Method for producing agricultural calcium-magnesium fertilizer by utilizing byproduct sulfuric acid

A sulfuric acid production and by-production technology, applied in the direction of magnesium fertilizer, calcium fertilizer, application, etc., can solve problems such as difficult operation, large investment, and environmental safety threats

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

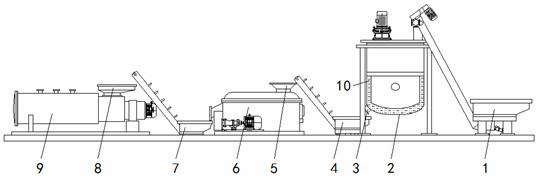

[0023] A kind of method utilizing by-product sulfuric acid to produce agricultural calcium magnesium fertilizer, comprises the following steps:

[0024] 1) Use the vertical feeder 1 to place a certain proportion of by-product sulfuric acid and the mixture of calcined dolomite or magnesite and marble ore in the mixing tank 2 for reaction. .

[0025] 2) Cool down to below 60 degrees after the reaction, add a certain amount of borax, zinc sulfate, and then add the mixture of microorganisms and organic matter.

[0026] 3) Then it is fully mixed through the mixing tank 2, and the material is exported to the conveyor 4 after the mixing is completed.

[0027] 4) The material is then introduced into the crusher 6 through the conveyor 4 for crushing, and after the crushing is completed, the material is introduced from the crusher 6 into the granulation feeder 7 .

[0028] 5) The material is introduced into the granulator 9 through the granulation feeding machine 7 for uniform granula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com