Underground cable protection pipe

A technology for underground cables and protective tubes, applied in the field of power cables, can solve problems such as poor flame retardancy and mechanical properties that need to be improved, and achieve the effect of prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

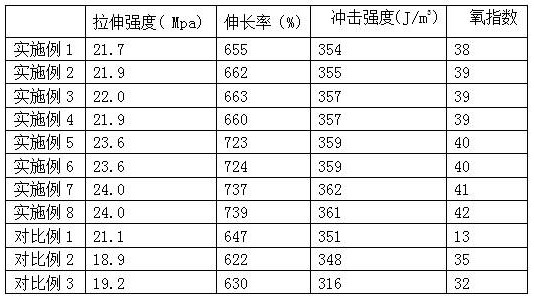

Examples

Embodiment 1

[0023] An underground cable protection tube includes a metal mesh and rubber layers wrapped on both sides of the metal mesh.

[0024] The rubber layer is made of the following raw materials in parts by weight: 25 parts of ethylene-propylene rubber, 12 parts of styrene-butadiene rubber, 4 parts of hydrogenated rosin glyceride, 1.5 parts of white carbon black, 0.8 parts of flame retardant, and 5.5 parts of attapulgite , 80 parts of acetone, 1.8 parts of filler. The flame retardant is triphenyl phosphate. The filler is zinc oxide. The particle size of the attapulgite is 200 mesh.

Embodiment 2

[0026] An underground cable protection tube includes a metal mesh and rubber layers wrapped on both sides of the metal mesh.

[0027] The rubber layer is made of the following raw materials in parts by weight: 27 parts of ethylene-propylene rubber, 15 parts of styrene-butadiene rubber, 6 parts of hydrogenated rosin glyceride, 1.8 parts of white carbon black, 1 part of flame retardant, and 6 parts of attapulgite , 85 parts of acetone, 2 parts of filler.

[0028] The flame retardant is ammonium polyphosphate.

[0029] The filler is a mixture of silicon nitride, nanometer titanium dioxide and zinc oxide, and the weight ratio of silicon nitride: nanometer titanium dioxide: zinc oxide is 1:0.3:2. The particle size of the attapulgite is 200 mesh.

Embodiment 3

[0031] An underground cable protection tube includes a metal mesh and rubber layers wrapped on both sides of the metal mesh.

[0032] The rubber layer is made of the following raw materials in parts by weight: 28 parts of ethylene-propylene rubber, 16 parts of styrene-butadiene rubber, 7 parts of hydrogenated rosin glyceride, 2.2 parts of white carbon black, 1.2 parts of flame retardant, and 7 parts of attapulgite , 90 parts of acetone, 2.2 parts of filler.

[0033] The flame retardant is triphenyl phosphate or ammonium polyphosphate.

[0034] The filler is a mixture of silicon nitride, nanometer titanium dioxide and zinc oxide, and the weight ratio of silicon nitride: nanometer titanium dioxide: zinc oxide is 1:0.4:2.5. The particle size of the attapulgite is 300 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com