Substrate-free removable rubber-based pressure-sensitive adhesive

A substrate-free, pressure-sensitive adhesive technology, used in pressure-sensitive films/sheets, adhesives, film/sheet-like adhesives, etc., to solve problems such as incomplete removal, contamination by stickers, and strong insensitivity , to achieve a good user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

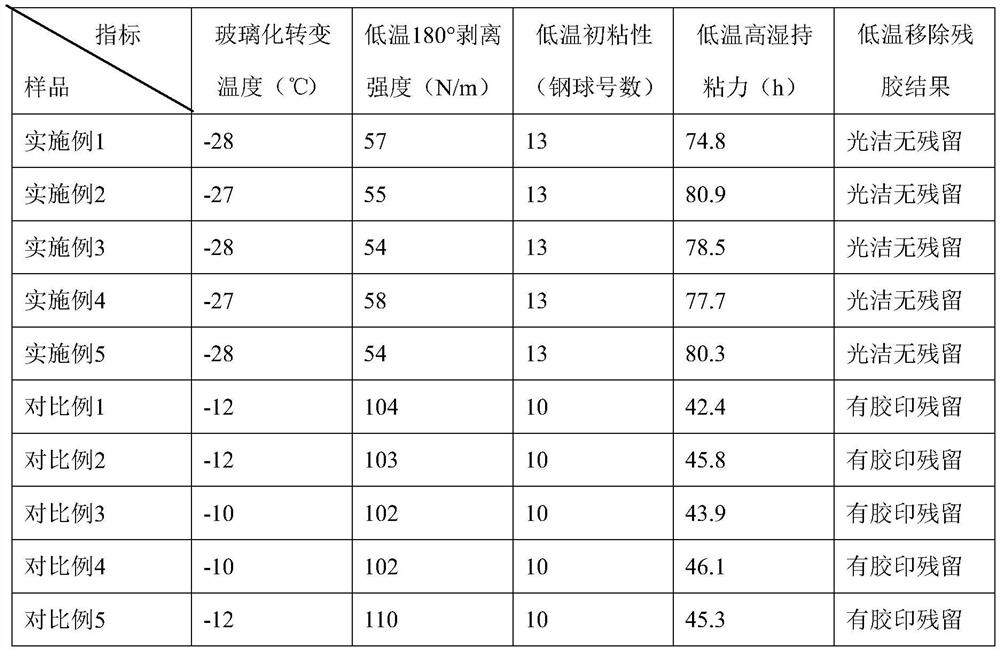

Examples

Embodiment 1

[0020]40 parts of SIS, 12 parts of 4010, 40 parts of terpene resin, 4 parts of rosin glycerides, 1 part of nano silica, 1682 parts of antioxidants, 10102 parts of antioxidants. The relative molecular weight of elastomer SIS is 10×104, S / I block ratio is 20%.

[0021]The preparation steps of the above pressure-sensitive adhesive are:

[0022]1) Glue making: under the protection of nitrogen, first add the formula amount of naphthenic oil, elastomer and antioxidant into the reactor, control the material temperature at 180-200℃, stir at the speed of 120r / min to melt, and then add Rosin glyceride, terpene resin and nano-silica were stirred for 2 hours until it became transparent and then continued stirring for 0.5 hours.

[0023]2) Coating: Pour the pressure-sensitive adhesive into the glue box of the hot melt pressure-sensitive adhesive coating machine. The glue box maintains a constant temperature of 180°C, the temperature of the hose is 170°C, the coating temperature is 175°C, and the multilay...

Embodiment 2

[0025]20 parts of SIS, 5 parts of 4010, 20 parts of terpene resin, 1 part of rosin glyceride, 0.2 part of nano-silica, 168 1 part of antioxidant, and 1010 1 part of antioxidant. The relative molecular weight of elastomer SIS is 12×104, S / I block ratio is 20%.

[0026]The preparation steps of the pressure-sensitive adhesive are the same as in Example 1.

Embodiment 3

[0028]SIS 75 parts, 4010 40 parts, terpene resin 60 parts, rosin glyceride 10 parts, nano silica 1.5 parts, antioxidant 168 4 parts, antioxidant 10104 parts. The relative molecular weight of elastomer SIS is 8×104, S / I block ratio is 20%.

[0029]The preparation steps of the pressure-sensitive adhesive are the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com