Preparation method and application of core-shell structure microcapsule particles

A core-shell structure and microcapsule technology is applied in the field of preparation of core-shell structure microcapsule particles, which can solve the problems of difficulty in assembly and single shape of the microcapsule, and achieve the effects of good digestion effect, slow digestion effect and application prospect improvement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038]Example 1: Preparation of spherical hydrophilic-hydrophobic core-shell microcapsule particles.

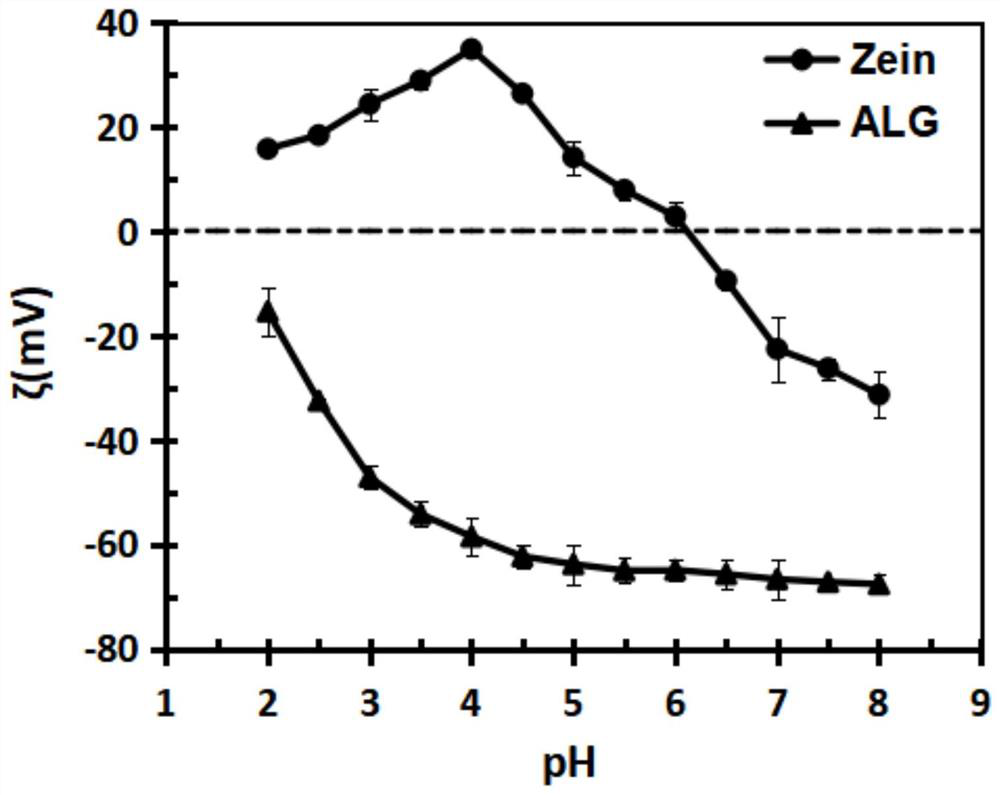

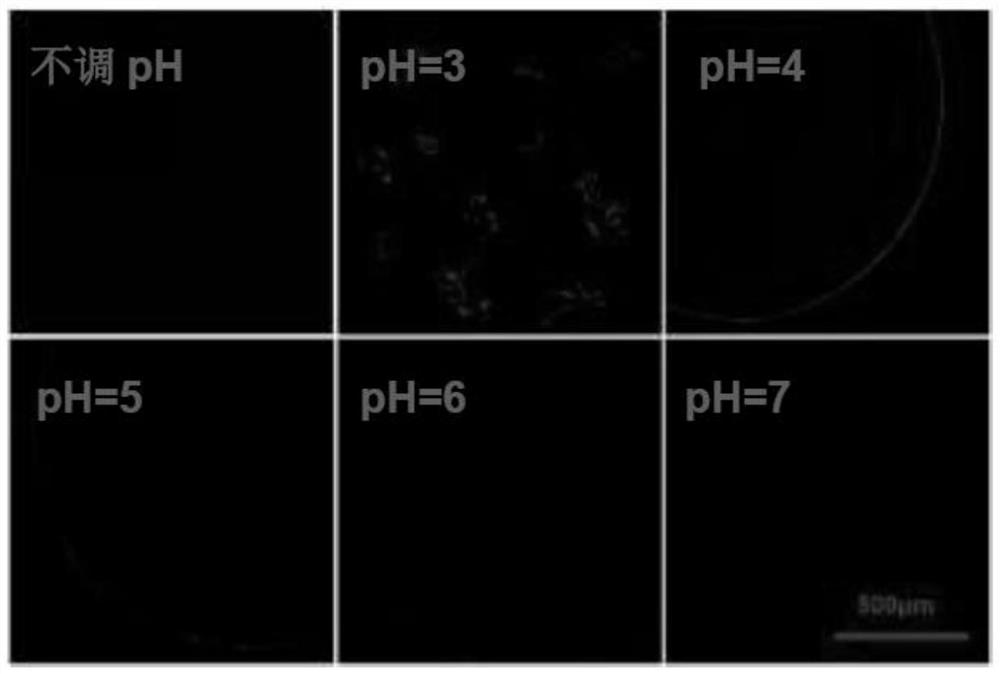

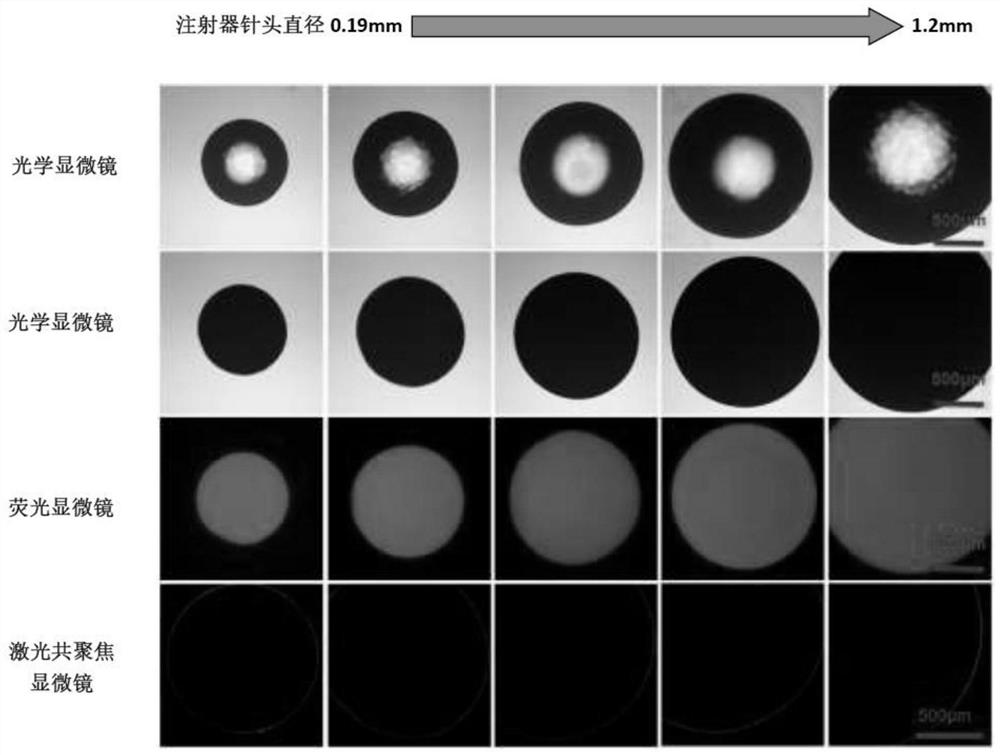

[0039] 1) Preparation of hydrophilic nucleosome gel particles: prepare 100 g (1% w / w) of sodium alginate solution with ultrapure water (the concentration of sodium alginate can be 1-3% (w / w), the present embodiment Preferred 1% (w / w)) and calcium chloride solution 200g (5% w / w) (the concentration of calcium chloride solution can be 5-10% (w / w), the preferred 5% (w / w) of present embodiment w)), and adjust the pH of the prepared sodium alginate and calcium chloride solution to 4 (the pH range can be 3-5, preferably 4 in this embodiment). Draw the sodium alginate solution through a syringe (the needle diameter is 0.19mm, 0.3mm, 0.45mm, 0.6mm and 1.2mm), and drop it drop by drop at 0.3mL / min at a distance of 5cm from the surface of the 5% (w / w) calcium chloride solution , standing still for 30 minutes to prepare spherical hydrophilic nucleosome gel particles of different sizes. ...

Embodiment 2

[0043] Example 2: Preparation of ellipsoidal hydrophilic-hydrophobic core-shell microcapsule particles.

[0044] 1) Preparation of hydrophilic nucleosome gel particles: prepare 100 g (1% w / w) of sodium alginate solution with ultrapure water (the concentration of sodium alginate can be 1-3% (w / w), the present embodiment Preferred 1% (w / w)), high concentration calcium chloride solution 200g (5% w / w) (the concentration of calcium chloride solution can be 5-10% (w / w), the preferred 5% of the present embodiment ( w / w)) and low concentration calcium chloride solution 200g (0.2%w / w) (the concentration of calcium chloride solution can be 0.1-0.3% (w / w), the preferred 0.2% (w / w) of the present embodiment ), and the pH of the prepared sodium alginate and calcium chloride solution is adjusted to 4 (the pH range can be 3-5, preferably 4 in this embodiment). Draw the sodium alginate solution through a syringe (needle diameters of 0.19mm, 0.3mm, 0.45mm, 0.6mm and 1.2mm), drop in 0.2% (w / w)...

Embodiment 3

[0047] Example 3: Preparation of fibrous hydrophilic-hydrophobic core-shell microcapsule particles.

[0048] 1) Preparation of hydrophilic nucleosome gel particles: prepare 100 g (1% w / w) of sodium alginate solution with ultrapure water (the concentration of sodium alginate can be 1-3% (w / w), the present embodiment Preferred 1% (w / w)) and calcium chloride solution 200g (5% w / w) (the concentration of calcium chloride solution can be 5-10% (w / w), the preferred 5% (w / w) of present embodiment w)), and adjust the pH of the prepared sodium alginate and calcium chloride solution to 4 (the pH range can be 3-5, preferably 4 in this embodiment). Draw the sodium alginate solution through a syringe (needle diameters of 0.6mm, 0.7mm, 0.8mm, 0.9mm and 1.2mm), and extend it into the 5% (w / w) calcium chloride solution below the liquid surface for continuous extrusion. Let stand for 30min to prepare fibrous hydrophilic nucleosome gel particles of different sizes. The first row and the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com