A split type constant pressure cylindrical honing structure and using method

A constant pressure, split-type technology, applied in the field of mechanical honing, can solve the problems of inconvenient fit between the whetstone bar and the workpiece, poor floating of the honing head, and lack of floating structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

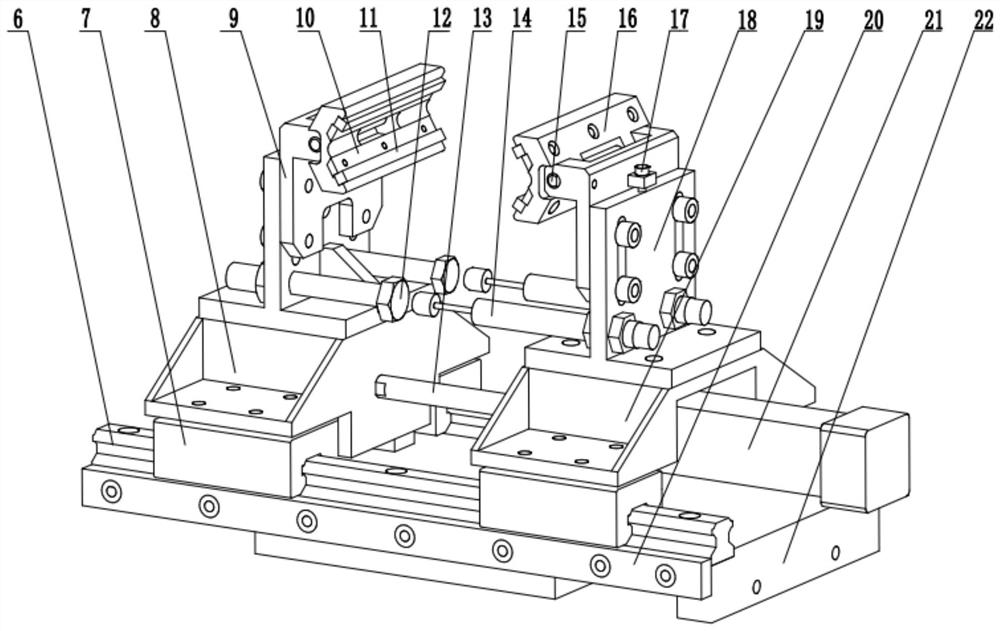

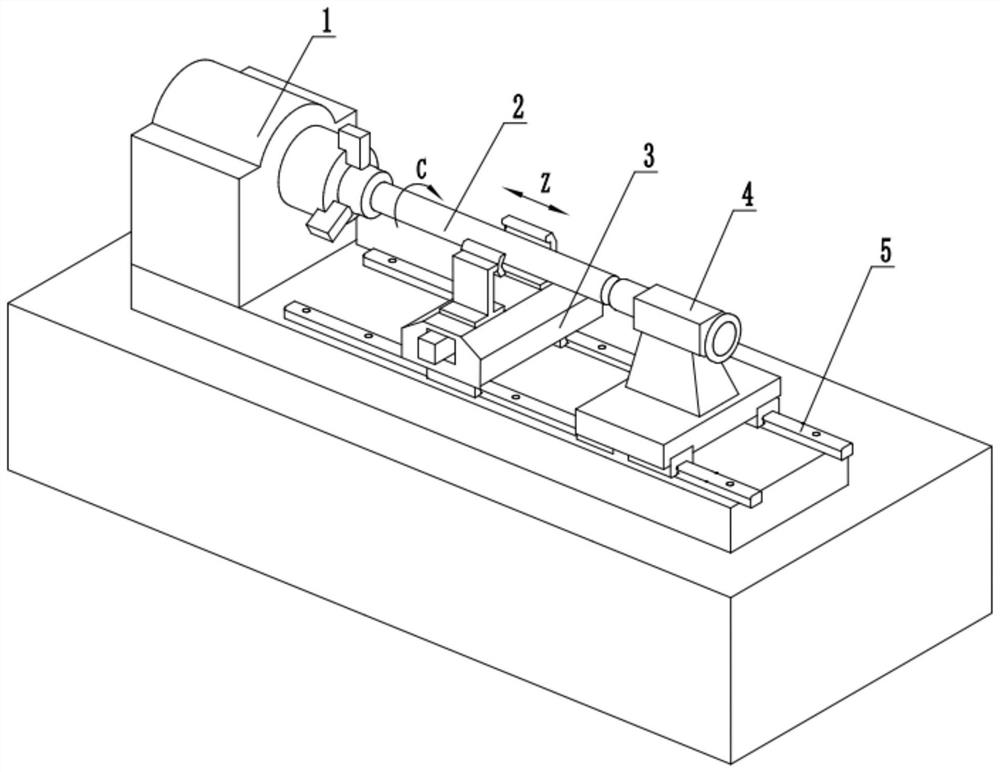

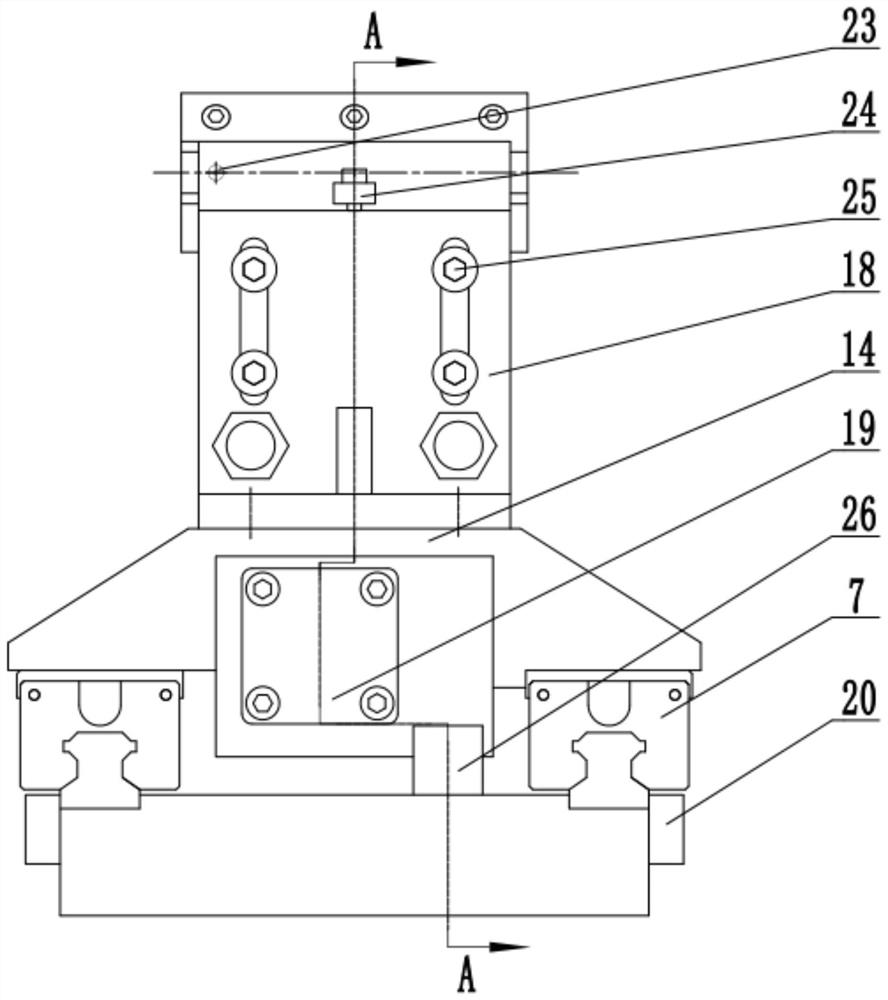

[0030] The present invention will be further described below in conjunction with the accompanying drawings.

[0031] Such as Figure 1-5 As shown, the present invention clamps the workpiece 2 between the headstock 1 and the tailstock 4 before starting machining, and the workpiece 2 should pass between the two honing heads. After the clamping is completed, supply air to the cylinder and adjust the air intake rate of the cylinder so that the piston rod 13 shrinks at a slower speed. At this time, the two honing heads will move toward each other along the direction of the guide rail 6 under the action of the cylinder. The buffer structure added on the two honing heads can cause the damped displacement of the two honing heads. When the two honing heads move toward each other to a certain position, The buffer head 32 of the buffer 14 is in contact with the bolt head of the adjusting bolt 12 to generate damping, which again slows down the speed of the two honing heads moving toward ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com