Racing boat with high polymer material and preparation method thereof

The technology of a polymer material and a manufacturing method, which is applied to a racing boat with a polymer material and its preparation, and the field of racing boat and its preparation, can solve the problems of complex production process, friction resistance, complicated process, etc., and achieve a simple production process. , low cost, simple adhesion process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

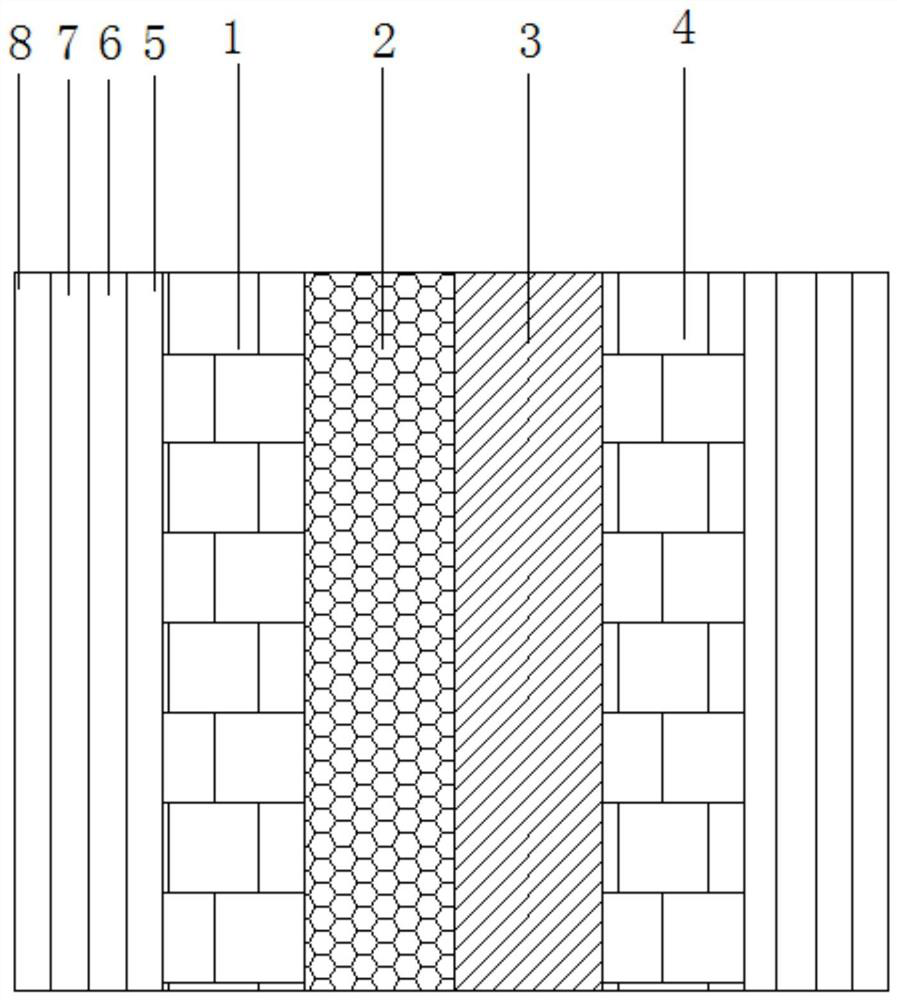

[0022] Embodiment 1: as figure 1 Shown is a specific embodiment of a racing boat with a polymer material, a racing boat with a polymer material, including a hull, and the hull includes inner fiber prepreg layers that are sequentially adhered from the inside to the outside 1. Aramid honeycomb sandwich core 2, PVC inner panel 3, outer fiber prepreg layer 4, the inner fiber prepreg layer 1, outer fiber prepreg layer 4 are sequentially provided with carbon and aromatic mixed prepreg Layer 5, aramid prepreg layer 6, carbon cloth 7, paint layer 8, the aramid prepreg layer 6 includes several radially arranged carbon fibers and several weftwise arranged aramid fibers;

[0023] A kind of manufacture method of the racing boat with polymer material of the present invention, the step of this manufacture method comprises:

[0024] Step 1): Laying and bonding the inner fiber prepreg layer 1, the aramid honeycomb sandwich core 2, the PVC inner panel 3, and the outer fiber prepreg layer 4 fr...

Embodiment 2

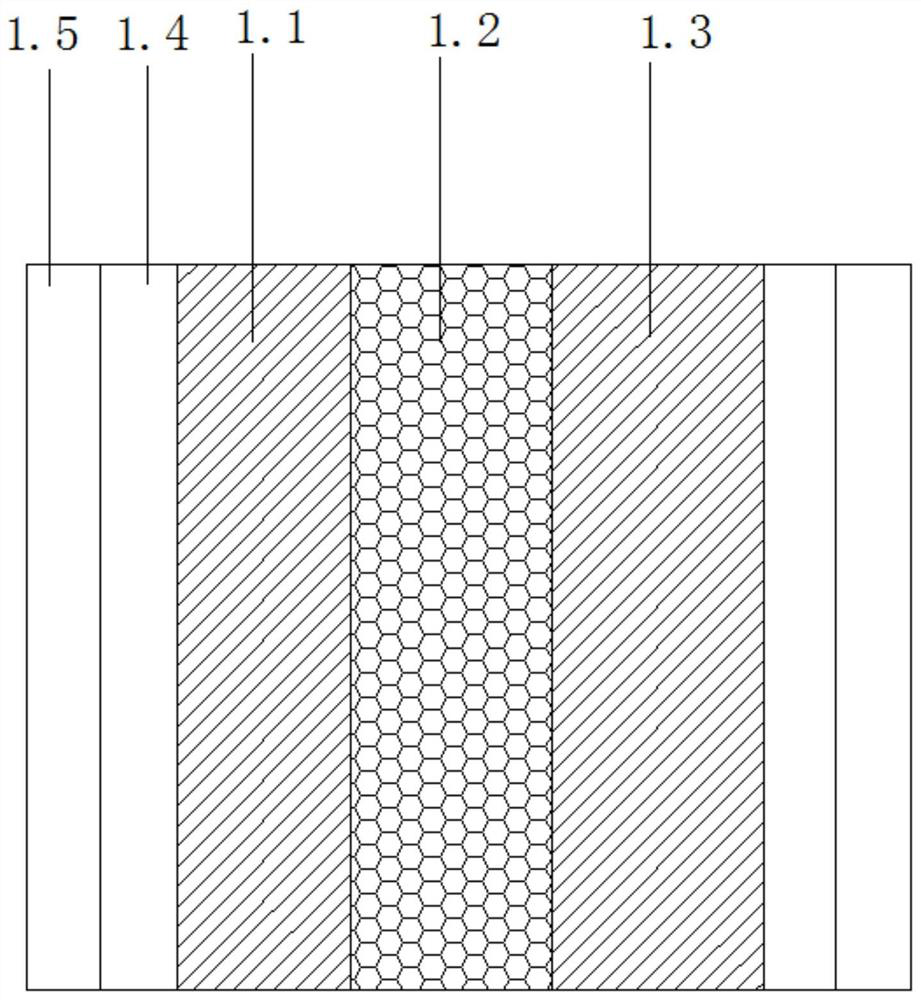

[0030] Embodiment 2: A rowing boat with a polymer material according to the present invention, including a hull. The hull includes an inner skin imported spun fabric 1.1, an aramid honeycomb sandwich core 1.2, and an outer sheath that are sequentially adhered from the inside to the outside. Imported textile cloth 1.3 for leather, carbon cloth 1.4 and carbon belt 1.5 for the inner skin imported textile cloth 1.1 and outer skin imported textile cloth 1.3.

Embodiment 3

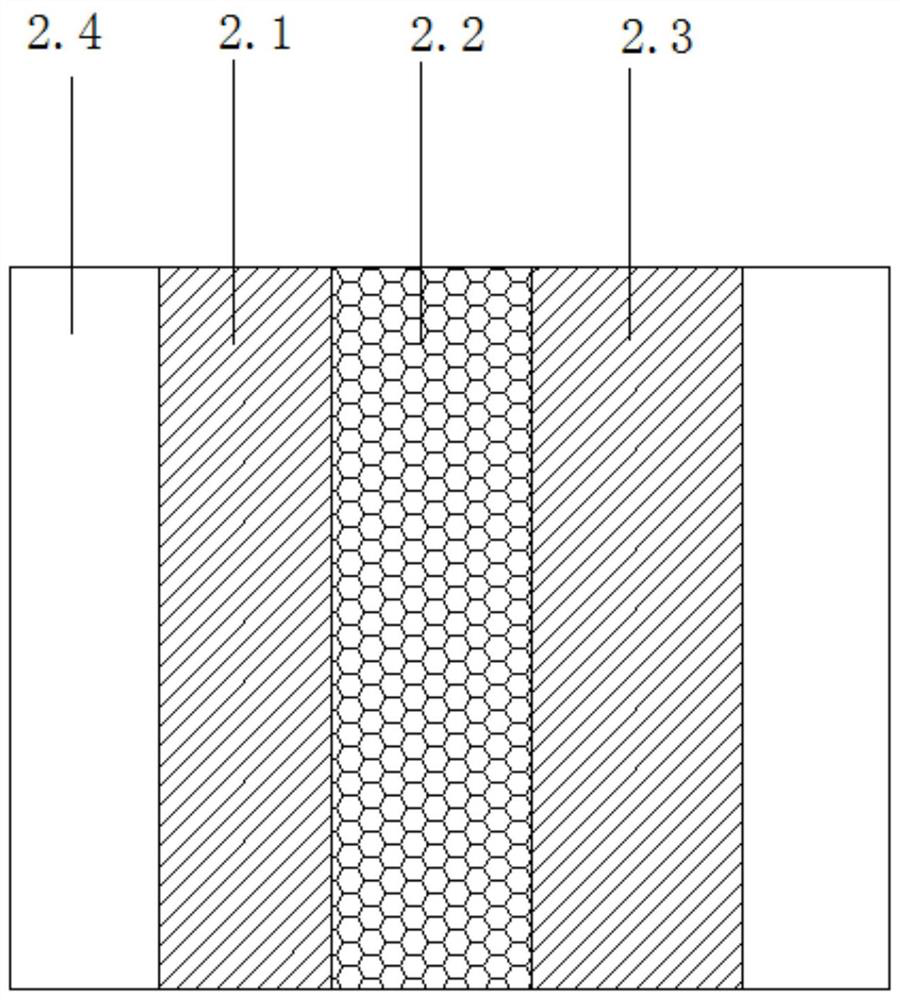

[0031] Embodiment 3: A racing boat with a polymer material according to the present invention, including a hull. The hull includes an inner full carbon fiber layer 2.1, an aramid honeycomb sandwich core 2.2, and an outer full carbon fiber layer 2.1 adhered sequentially from the inside to the outside. The carbon fiber layer 2.3, the inner full carbon fiber layer 2.1 and the outer full carbon fiber layer 2.3 are all provided with carbon belts for reinforcement.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com