Preparation method of ethylene propylene diene monomer plate

A technology of EPDM rubber and EPDM, which is applied in the field of rubber, can solve the problems of difficult mixing of EPDM rubber, and achieve the effects of improving poor compatibility, increasing strength and toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

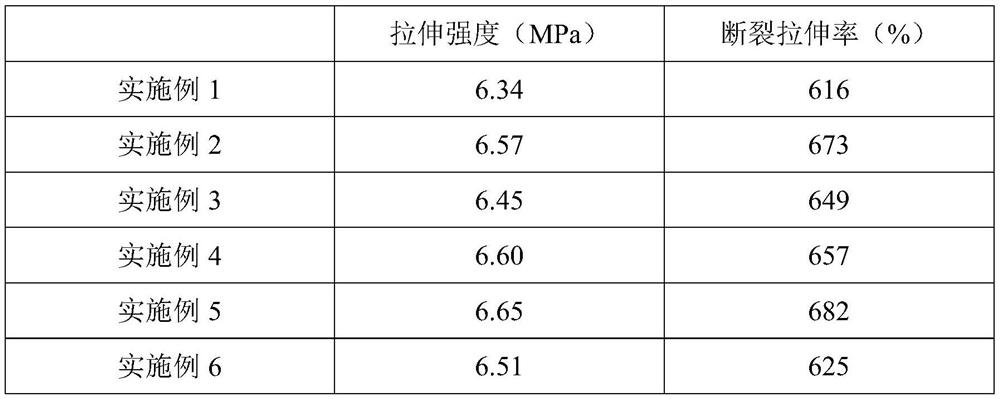

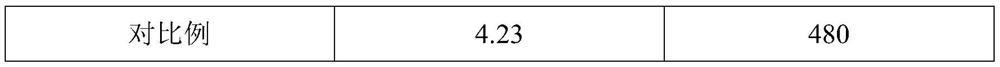

Examples

Embodiment 1

[0023] A kind of preparation method of EPDM sheet is as follows:

[0024] Step 1, adding EPDM rubber, natural rubber and maleic anhydride to a pulverizer for pulverization, and stirring uniformly to form a mixture, the pulverization pressure is 2MPa, and the temperature is 20°C;

[0025] Step 2, adding the mixture and the initiator to the mixing equipment and kneading to obtain a mixed cross-linked resin, wherein the mixing temperature is 170°C, the mixing speed is 1000r / min, and the mixing time is 10min;

[0026] Step 3, adding the mixed cross-linked resin and antioxidant into the reactor and kneading to obtain the modified EPDM rubber; wherein, the kneading temperature is 160°C, the kneading stirring speed is 500r / min, and the time is 10min;

[0027] Step 4: Put the vulcanizing agent and filler into the reactor and stir evenly, then vulcanize and extrude to make EPDM sheet. The temperature of the vulcanization treatment is 160°C, the pressure is 10MPa, and the time is 60min...

Embodiment 2

[0035] A kind of preparation method of EPDM sheet is as follows:

[0036] Step 1, adding EPDM rubber, natural rubber and maleic anhydride to a pulverizer for pulverization, and stirring evenly to form a mixture, the pulverization pressure is 5MPa, and the temperature is 40°C;

[0037] Step 2, adding the mixture and the initiator to the mixing equipment and kneading to obtain a mixed cross-linked resin, wherein the mixing temperature is 170°C, the mixing speed is 1500r / min, and the mixing time is 30min;

[0038] Step 3, adding the mixed cross-linked resin and antioxidant into the reactor and kneading to obtain the modified EPDM rubber; wherein, the kneading temperature is 160°C, the kneading stirring speed is 1000r / min, and the time is 30min;

[0039] Step 4: Put the vulcanizing agent and filler into the reactor and stir evenly, then vulcanize and extrude to make EPDM sheet. The temperature of vulcanization is 160°C, the pressure is 10MPa, and the time is 90min.

[0040] Amon...

Embodiment 3

[0047] A kind of preparation method of EPDM sheet is as follows:

[0048] Step 1, adding EPDM rubber, natural rubber and maleic anhydride to a pulverizer for pulverization, and stirring evenly to form a mixture, the pulverization pressure is 4MPa, and the temperature is 30°C;

[0049] Step 2, adding the mixture and the initiator to the mixing equipment and kneading to obtain a mixed cross-linked resin, wherein the mixing temperature is 170°C, the mixing speed is 1400r / min, and the mixing time is 15min;

[0050] Step 3, adding the mixed cross-linked resin and antioxidant into the reactor and kneading to obtain the modified EPDM rubber; wherein, the kneading temperature is 160°C, the kneading stirring speed is 800r / min, and the time is 20min;

[0051] Step 4: Put the vulcanizing agent and filler into the reactor and stir evenly, then vulcanize and extrude to make EPDM sheet. The temperature of vulcanization is 160°C, the pressure is 10MPa, and the time is 70min.

[0052] Among...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com