A kind of flame-retardant hemp fiber/thermoplastic polymer composite board and preparation method thereof

A thermoplastic polymer and hemp fiber technology, which is applied in the field of flame retardant hemp fiber/thermoplastic polymer composite board and flame retardant sheet, can solve the problems of environmental protection requirements and poor mechanical properties of flame retardant sheets, and achieve both flame retardant performance and mechanical properties. performance, widening application range, remarkable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

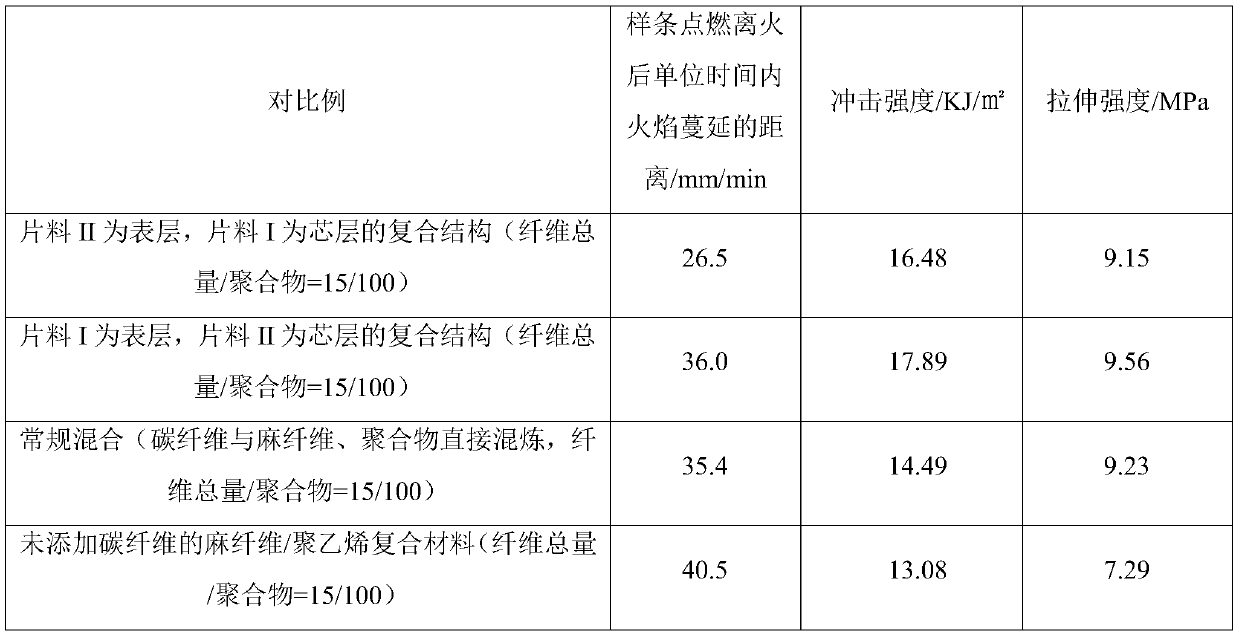

Embodiment 1

[0026] Soak the ramie fiber with 2% sodium hydroxide aqueous solution for 24 hours, then wash it with deionized water and dry it. Take by weighing the above-mentioned ramie fiber of 10g and 50g low-density polyethylene, put into the two-roll mill again and be mixed into composite sheet material and be sheet material I, wherein the front roller of the two-roll mill is 115 ℃, and the temperature of the back roller is 115°C. 110°C; 5g of recycled carbon fiber and 50g of low-density polyethylene were weighed, and then put into a two-roll mill to knead to form a composite material sheet, ie, sheet II. Among them, the temperature of the front roll of the double-roller mill is 115°C, and the temperature of the rear roll is 110°C; after cutting the sheet material I and sheet II according to the size of the mold, put the sheet material I between the two sheet materials II, Make it stacked into a composite structure of "sheet II-sheet I-sheet II", put it in a flat vulcanizer and heat-pr...

Embodiment 2

[0028] Soak the ramie fiber with 2% sodium hydroxide aqueous solution for 24 hours, then wash it with deionized water and dry it. Take by weighing the above-mentioned ramie fiber of 10g and 50g low-density polyethylene, put into the two-roll mill again and be mixed into composite sheet material and be sheet material I, wherein the front roller of the two-roll mill is 115 ℃, and the temperature of the back roller is 115°C. 110°C; 5g of recycled carbon fiber and 50g of low-density polyethylene were weighed, and then put into a two-roll mill to knead to form a composite material sheet, ie, sheet II. Among them, the temperature of the front roll of the double-roll mill is 115°C, and the temperature of the rear roll is 110°C; after the sheet I and sheet II are cut according to the size of the mold, the sheet II is placed between the two sheets I, Make it stacked into a composite structure of "sheet I-sheet II-sheet I", put it in a flat vulcanizer and heat-press it into a plate (hot...

Embodiment 3

[0030] Soak the ramie fiber with 2% sodium hydroxide aqueous solution for 24 hours, then wash it with deionized water and dry it. Take by weighing 10g of the above-mentioned ramie fiber, 5g of recycled carbon fiber, and 100g of low-density polyethylene and mix them into composite material flakes in a two-roll mill, wherein the temperature of the front roll of the two-roll mill is 115°C, and the temperature of the rear roll is 110°C . After the composite material sheet is cut according to the size of the mold, it is placed in a flat vulcanizer and hot-pressed into a plate (hot-pressing temperature is 140°C, hot-pressing time is 10min) and made into a sample, and its mechanical properties are tested and the ignition of the sample is recorded. The distance the flame spreads within 1 minute from the fire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com