Flame-retardant adhesive for surface of artificial board as well as preparation method and application thereof

A technology of wood-based panels and flame-retardant adhesives, which is applied in the direction of adhesives, adhesive additives, film/sheet adhesives, etc., can solve the problems of unstable flame-retardant performance, cumbersome preparation process, and increased process difficulty, and achieve compactness good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

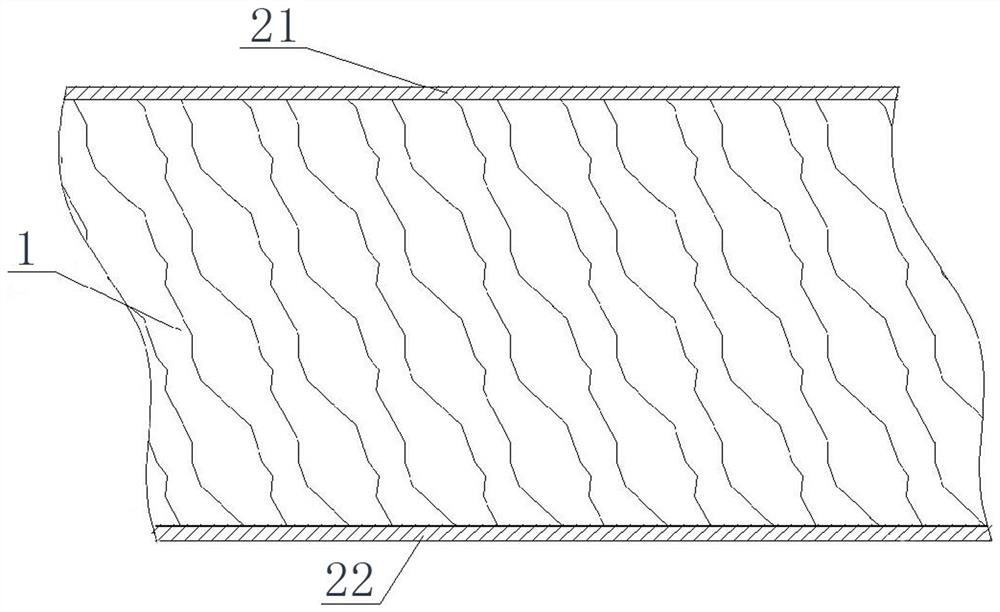

[0027] Embodiment 1 A kind of preparation method of surface flame retardant wood-based panel

[0028] 1) A method for preparing a flame-retardant adhesive used on the surface of wood-based panels

[0029] Take 100kg of melamine formaldehyde resin, add 100g of methylcellulose and 5kg of urea, stir until the methylcellulose and urea are completely mixed with the melamine formaldehyde resin, then slowly add 60kg of flame retardant, continue stirring until all materials are completely mixed evenly, that is The flame retardant adhesive (marked as M1) used on the surface of wood-based panels is obtained, and the obtained flame retardant adhesive M1 is generally controlled to be used up within 3 hours.

[0030] The flame-retardant adhesive M1 prepared in this example for the surface of the wood-based panel is used to coat the surface of the wood-based panel to prepare the flame-retardant wood-based panel N1 with visualized wood grain texture.

[0031] 2) A preparation method of surf...

Embodiment 2~11

[0038] Embodiment 2~11 the preparation method of surface flame-retardant wood-based panel

[0039] Examples 2 to 11 are respectively a method for preparing a surface flame-retardant wood-based panel. Their steps are basically the same as in Example 1. The only difference lies in the amount of raw materials and process parameters. For details, see Table 1:

[0040] Table 1 List of process parameters

[0041]

[0042]

[0043] The content of the other parts of Examples 2-11 is the same as that of Example 1.

Embodiment 12

[0044] Embodiment 12 Performance test experiment of surface flame-retardant wood-based panel

[0045] 1) Preparation of flame-retardant adhesives for the surface of wood-based panels and surface flame-retardant wood-based panels of comparative examples D1-D4

[0046] Comparative Examples D1-D4 respectively prepared a surface flame-retardant wood-based panel. The steps of their preparation methods were basically the same as those in Example 1, the only difference being the amount of raw materials and process parameters. See Table 2 for details:

[0047] Table 2 List of process parameters

[0048]

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap