Hydrogen overflow-based biomass catalytic hdyroprocessing rapid pyrolysis device and method

A biomass and overflow technology, which is used in the preparation of liquid hydrocarbon mixtures, the petroleum industry, and the treatment of hydrocarbon oil. Value utilization, enhance hydrocarbon generation performance, and promote the effect of supplementing and replacing traditional fossil energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0057] Include the following steps:

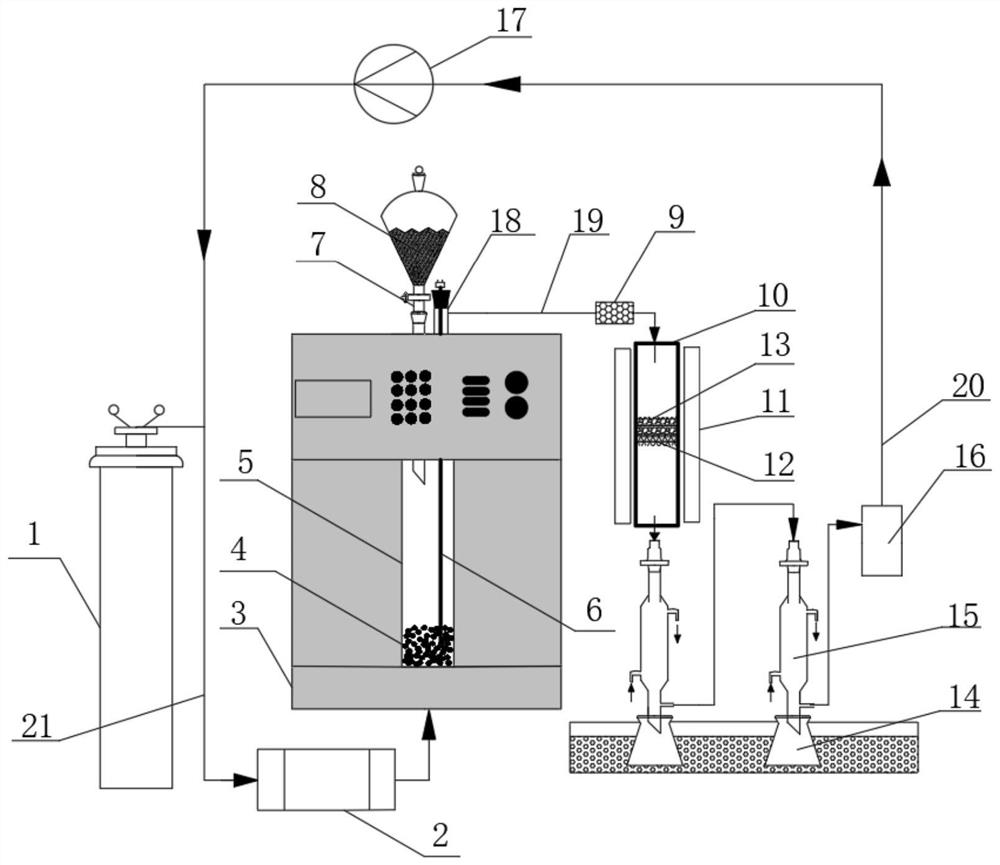

[0058] Step 1: Fill 50g of alumina particles 4 in the bubbling fluidized bed reactor, fill the feeder 7 with biomass raw material 8, Pt / TiO 2 The mixing ratio with ZSM-5 molecular sieve is 1:3, according to figure 1 The connection relationship shown connects the fast pyrolysis device;

[0059] Step 2: Open the valve of the hydrogen cylinder 1, adjust the hydrogen flow rate so that it flows through the carrier gas preheater 2 to preheat the hydrogen temperature to 275°C, and ensure that the alumina particles 4 in the bubbling fluidized bed reactor can be normal Fluidization, exhaust the air in the device;

[0060] Step 3: Send 10g of biomass raw material 8 into the bubbling fluidized bed reactor by using the feeder 7 to ensure that the composite catalyst 13 is 1 / 3 of the quality of the biomass raw material 8; start the pyrolysis reaction to generate pyrolysis gas, The pyrolysis temperature is 400°C, and the pyrolysis gas passes through t...

specific Embodiment 2

[0063] Include the following steps:

[0064] Step 1: Fill 50g of alumina particles 4 in the bubbling fluidized bed reactor, fill the feeder 7 with biomass raw material 8, Pt / TiO 2 The mixing ratio with ZSM-5 molecular sieve is 1:3, according to figure 1 The connection relationship shown connects the fast pyrolysis device;

[0065] Step 2: Open the hydrogen gas source 1 valve, adjust the hydrogen flow rate so that it flows through the carrier gas preheater 2 to preheat the hydrogen temperature to 275°C, and ensure that the alumina particles 4 in the bubbling fluidized bed reactor can be normal Fluidization, exhaust the air in the device;

[0066] Step 3: Send 10g of biomass raw material 8 into the bubbling fluidized bed reactor by using the feeder 7 to ensure that the composite catalyst 13 is 1 / 3 of the quality of the biomass raw material 8; start the pyrolysis reaction to generate pyrolysis gas, The pyrolysis temperature is 300°C, and the pyrolysis gas passes through the as...

specific Embodiment 3

[0069] Include the following steps:

[0070] Step 1: Fill 50g of alumina particles 4 in the bubbling fluidized bed reactor, fill the feeder 7 with biomass raw material 8, Pt / TiO 2 The mixing ratio with ZSM-5 molecular sieve is 3:1, according to figure 1 The connection relationship shown connects the fast pyrolysis device;

[0071] Step 2: Open the hydrogen gas source 1 valve, adjust the hydrogen flow rate so that it flows through the carrier gas preheater 2 to preheat the hydrogen temperature to 275°C, and ensure that the alumina particles 4 in the bubbling fluidized bed reactor can be normal Fluidization, exhaust the air in the device;

[0072] Step 3: Use the feeder 7 to send 10g of the biomass raw material 8 into the bubbling fluidized bed reactor to ensure that the composite catalyst 13 is three times the quality of the biomass raw material 8; start the pyrolysis reaction to generate pyrolysis gas, heat The pyrolysis temperature is 400°C, the pyrolysis gas passes throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com