Road and bridge engineering concrete crack control method

A technology of road and bridge engineering and control methods, applied in roads, bridges, roads, etc., can solve the problems of reducing structural durability, easy corrosion, and endangering the safe use of roads and bridges, and achieve excellent ductility and resilience, and good low-temperature embrittlement resistance performance, good high temperature stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

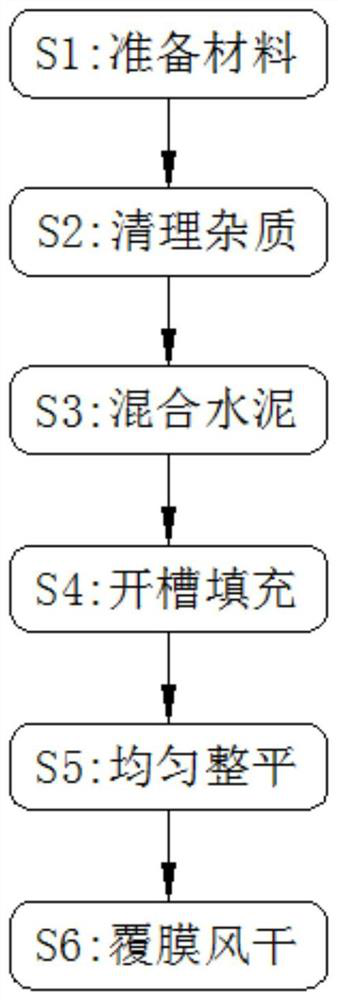

[0018] The invention provides a technical solution: a method for controlling concrete cracks in road and bridge engineering, the production steps include the following: S1, preparation materials: prepare portland cement, stabilizer, additive, sand and gravel, acrylamide polymer and epoxy resin slurry material ; S2, clean up impurities: clean the surface of the concrete cracks, use a high-power vacuum cleaner to remove impurities inside or around the concrete cracks, and then use a high-pressure cleaner to wash the inside of the concrete cracks or around the concrete cracks , will continue to use the dryer to blow and dry the inside of the concrete crack or around the concrete crack; S3, mixed cement: put portland cement, stabilizer, additive and sand into the mixer respectively, and then add an appropriate amount of water , start the mixer to control high-speed mixing and stirring, the stirring speed of the stirring rod is controlled at 360r / min, and the time is controlled at 3...

example 2

[0020] The invention provides a technical solution: a method for controlling concrete cracks in road and bridge engineering, the production steps include the following: S1, preparation materials: prepare portland cement, stabilizer, additive, sand and gravel, acrylamide polymer and epoxy resin slurry material ; S2, clean up impurities: clean the surface of the concrete cracks, use a high-power vacuum cleaner to remove impurities inside or around the concrete cracks, and then use a high-pressure cleaner to wash the inside of the concrete cracks or around the concrete cracks , will continue to use the dryer to blow and dry the inside of the concrete crack or around the concrete crack; S3, mixed cement: put portland cement, stabilizer, additive and sand into the mixer respectively, and then add an appropriate amount of water , start the mixer to control high-speed mixing and stirring, the stirring speed of the stirring rod is controlled at 480r / min, and the time is controlled at 5...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com