Chain grate and rotary kiln pellet roasting flue gas denitration process

A technology of grate machine and rotary kiln, which is applied in the field of waste gas treatment and can solve the problems of stable operation of flue gas denitrification and knocking

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The technical solutions of the present invention will be further described below through specific embodiments. It should be clear to those skilled in the art that the embodiments are only for helping to understand the present invention, and should not be regarded as specific limitations on the present invention.

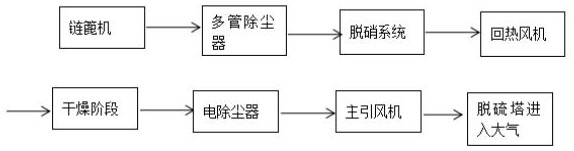

[0025] A chain grate-rotary kiln pellet roasting flue gas denitrification process, the process includes a chain grate, a multi-pipe dust collector, a denitrification system, a heat recovery fan, a drying stage, an electric dust collector, a main induced draft fan, and a desulfurization tower.

[0026] The denitrification system includes an SCR part and a combustion heat supplement part. A hot blast stove system is installed in front of the multi-tube dust collector to stabilize the flue gas temperature at 320~350°C.

[0027] The fuel used in the hot stove system is coke oven gas. The denitrification system adopts medium-high temperature SCR flue gas denitrif...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com