Neodymium-iron-boron magnet and preparation method thereof

A technology of NdFeB and magnetic materials, which is applied in the manufacture of permanent magnets, magnets, magnetic objects, etc., can solve the problems of decreased magnetic field strength, magnetic induction intensity and magnetic energy product, etc., to reduce magnetic attenuation, increase coercive force, and improve Effects of corrosion resistance and wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0064] An NdFeB magnetic material comprises a magnetic material body and a composite coating arranged on the surface of the magnetic material body, and the composite coating includes an inner coating and an outer coating.

[0065] The magnetic body contains the following elements by weight: Nd: 17wt%, B: 0.6wt%, Pr: 6.0wt%, Dy: 2wt%, Al: 0.3wt%, Cu: 0.1wt%, Co: 0.1wt%, The rest is Fe.

[0066] The inner coating includes Cr: 7.3wt%, B: 2.4wt%, Dy: 4.25wt%, Gd: 2.7wt%, and the rest are Fe; the outer coating includes graphite: 17.3wt%, Nb: 2.82wt%; Ti : 23wt%; SiC: 6.7%; Mo: 1.13wt%, and the rest are Ni.

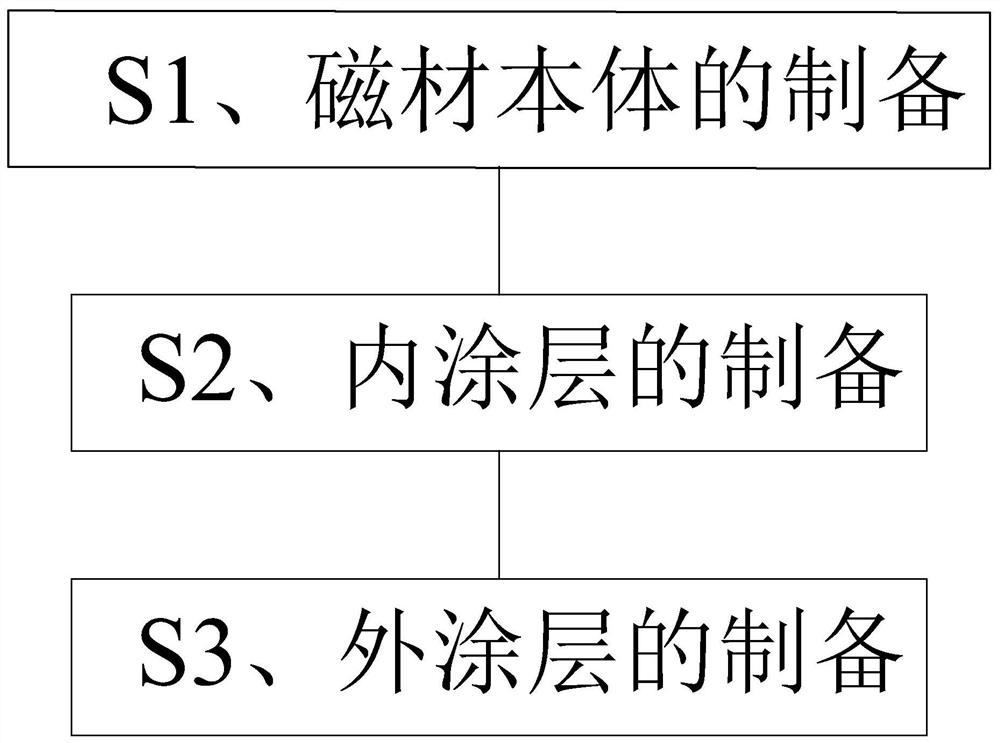

[0067] A method for preparing an NdFeB magnetic material, comprising S1, the preparation of a magnetic material body, and its specific steps include:

[0068] S1.1, mixing materials:

[0069] Pre-purchase the raw materials required for the main body of the magnetic material, and mix Nd, B, Pr, Dy, Al, Cu, Fe, Co in the above proportions to form a magnetic material mixed powd...

Embodiment 2-4

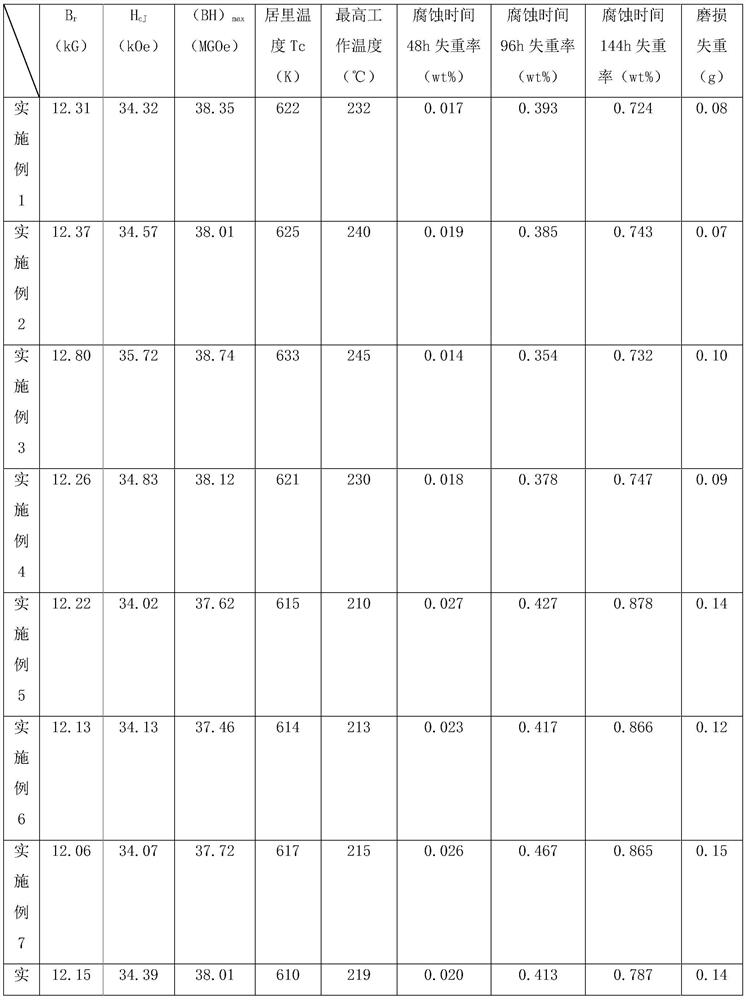

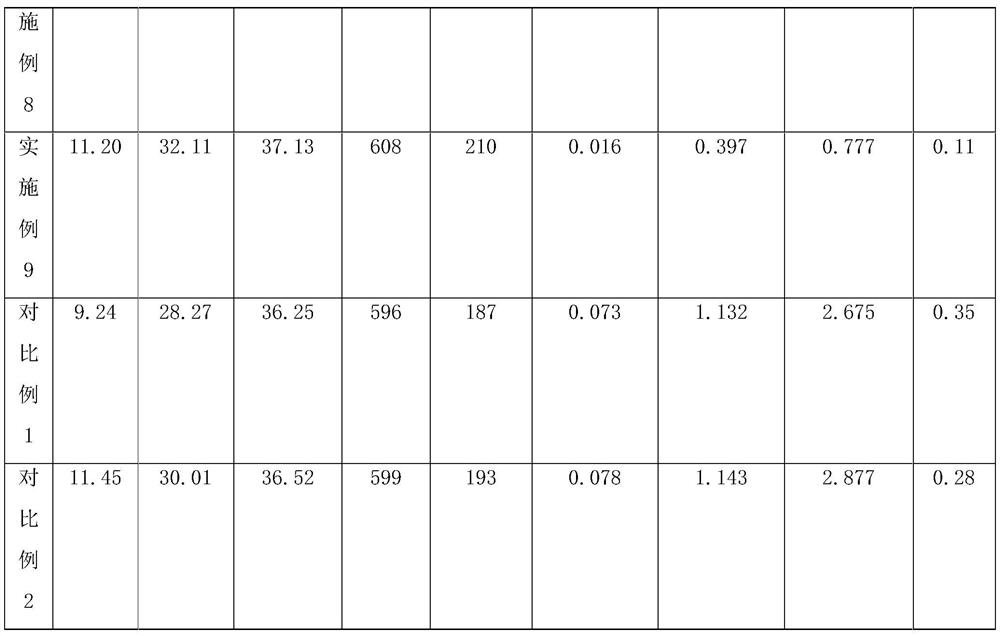

[0097] Embodiment 2-Embodiment 4 are all based on the method of Embodiment 1, and the content of each component of the magnetic material body is adjusted, and the specific adjustment is shown in Table 1 below.

[0098] Table 1 Component and component content table of embodiment 1-4

[0099] Example 1 Example 2 Example 3 Example 4 Nd 17 19 21 23 B 0.6 0.5 1.0 1.2 Pr 6 7 9 10 Dy 2 3 4 5 Al 0.3 0.4 0.6 0.9 Cu 0.1 0.12 0.17 0.20 co 0.1 0.12 0.13 0.15 Fe 73.9 69.86 64.1 59.55

Embodiment 5

[0101] The difference from Example 1 is that the magnetic material body does not undergo S1.7 nitriding treatment after S1.6 aging treatment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com