Suspension oil drop mouthwash and preparation method thereof

A technology for suspending oil and mouthwash, which is applied in the field of oral health care, can solve the problem of not being able to add a large amount of oil-soluble functional ingredients, and achieve the effects of avoiding impurities or solution stratification, ensuring stability, and improving the use effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

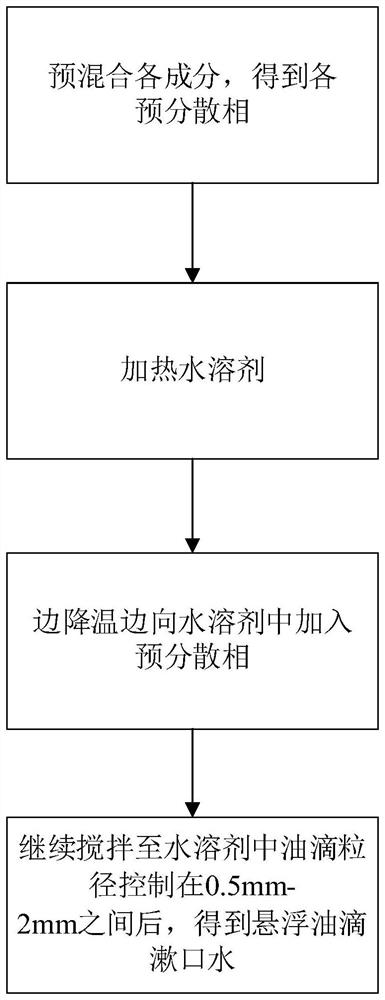

[0070] see figure 2 , the preparation method of suspended oil drop mouthwash provided by the application, comprises the following steps:

[0071] A. After pre-mixing the components, obtain pre-dispersed phase B, pre-dispersed phase D, pre-dispersed phase F, pre-dispersed phase G, pre-dispersed phase H, and pre-dispersed phase J;

[0072] B. After heating the water to 80-85°C, add the pre-dispersed phase B, 0.025 parts by weight of galactose, 0.5 parts by weight of xylitol, and 0.1 parts by weight of allantoin into the water and stir for 20 minutes, then stir Dissolve the translucent water agent without solid particles, and filter through 400 mesh to obtain the water phase components;

[0073] C. When the temperature of the water phase components drops to 40-48°C, add the pre-dispersed phase F to the water phase components; when the temperature of the water phase components drops to 35-40°C, mix the pre-dispersed phase E with the pre-dispersed phase D and add In the water ph...

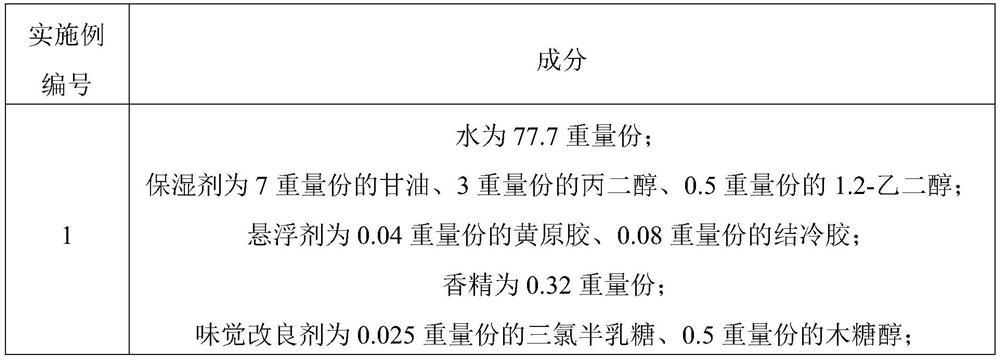

Embodiment 1~3

[0094] Gained mouthwash samples in Examples 1 to 3 are all prepared according to the following steps:

[0095] A. After pre-mixing the components, obtain pre-dispersed phase B, pre-dispersed phase D, pre-dispersed phase F, pre-dispersed phase G, pre-dispersed phase H, and pre-dispersed phase J;

[0096] Wherein, pre-dispersed phase B, pre-dispersed phase D, pre-dispersed phase F, pre-dispersed phase G, pre-dispersed phase H, pre-dispersed phase J mixing method comprises the following steps:

[0097] Pre-dispersed phase B: add the suspending agent to the humectant and mix, the pre-dispersed uniform, no particle agglomeration, to obtain the pre-dispersed phase B;

[0098] Pre-dispersed phase D: Mix the humectant and formulation stabilizer and dissolve in water, heat to 55-60°C, pre-disperse uniformly, confirm complete dissolution and transparency, cool down to room temperature, and obtain pre-dispersed phase D;

[0099] Pre-dispersed phase F: Pre-dispersed phase F is obtained a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com