Preparation method of dendritic-based nitrogen-doped mesoporous carbon and NiO-CoS2 composite electrode material

A nitrogen-doped mesoporous carbon and composite electrode technology, which is applied in the preparation/purification of carbon, chemical instruments and methods, cobalt compounds, etc., can solve the problems of harsh process conditions, uncontrollable reaction ratio, large particle size, etc. The preparation process is simple, the electrocatalytic activity is high, and the process conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1: A Dendrobium Nitrogen Doped Mesoporous Carbon and NiO-CoS 2 The preparation method of the composite electrode material is specifically completed according to the following steps:

[0019] 1. Pretreatment of tree tongue: take 80g tree tongue, add 100mL 0.5mol / L NaOH solution, soak in a water bath at 40°C for 30-50 minutes, control the ultrasonic frequency to 50kHz for 40 minutes, wash with distilled water until neutral, and put it in an oven Dry at 80°C, then pulverize, add 0.5mol / L HNO 3 solution, stirred at a constant speed for 7 to 10 hours, washed with distilled water until neutral, and dried in vacuum at 60°C for use;

[0020] 2. Preparation of composites of nitrogen-doped mesoporous carbon and NiO: put the sample obtained in step 1 into 1.0 mol / L Ni(NO 3 ) 2 In solution, the tongue and Ni(NO 3 ) 2 The mass ratio is 4:1, after stirring at a constant speed for 12 to 24 hours, vacuum-dry at 60°C, then put the sample into a tube furnace, and gradually h...

Embodiment 2

[0026] Example 2: A Dendrobium Nitrogen Doped Mesoporous Carbon and NiO-CoS 2 The preparation method of the composite electrode material is specifically completed according to the following steps:

[0027] 1. Pretreatment of tree tongue: Take tree tongue as carbon source, add 150mL 0.5mol / L NaOH, soak in water bath at 40°C for 30-50min, control ultrasonic frequency at 50kHz for 50min, wash with distilled water until neutral, put Dry in an oven at 80°C, then pulverize, add 1.0mol / L HNO 3 solution, stirred at a constant speed for 7 to 10 hours, washed with distilled water until neutral, and dried in vacuum at 60°C for use;

[0028] 2. Preparation of composites of nitrogen-doped mesoporous carbon and NiO: put the sample obtained in step 1 into 1.0 mol / L Ni(NO 3 ) 2 In solution, the tongue and Ni(NO 3 ) 2 The mass ratio is 5:1, after stirring at a constant speed for 12 to 24 hours, vacuum-dry at 60°C, then put the sample into a tube furnace, and gradually heat up to an air at...

Embodiment 3

[0034] Example 3: A Dendrobium Nitrogen Doped Mesoporous Carbon and NiO-CoS 2 The preparation method of the composite electrode material is specifically completed according to the following steps:

[0035] 1. Pretreatment of tree tongue: Take tree tongue as carbon source, add 200mL 0.5mol / L NaOH, soak in water bath at 40°C for 30-50min, control ultrasonic frequency to 50kHz for 60min, wash with distilled water until neutral, put Dry in an oven at 80°C, then pulverize, add 2.0mol / L HNO 3 solution, stirred at a constant speed for 7 to 10 hours, washed with distilled water until neutral, and dried in vacuum at 60°C for use;

[0036] 2. Preparation of composites of nitrogen-doped mesoporous carbon and NiO: put the sample obtained in step 1 into 1.0 mol / L Ni(NO 3 ) 2 In solution, the tongue and Ni(NO 3 ) 2 The mass ratio is 6:1, after stirring at a constant speed for 12 to 24 hours, vacuum-dry at 60°C, then put the sample into a tube furnace, and gradually increase the tempera...

PUM

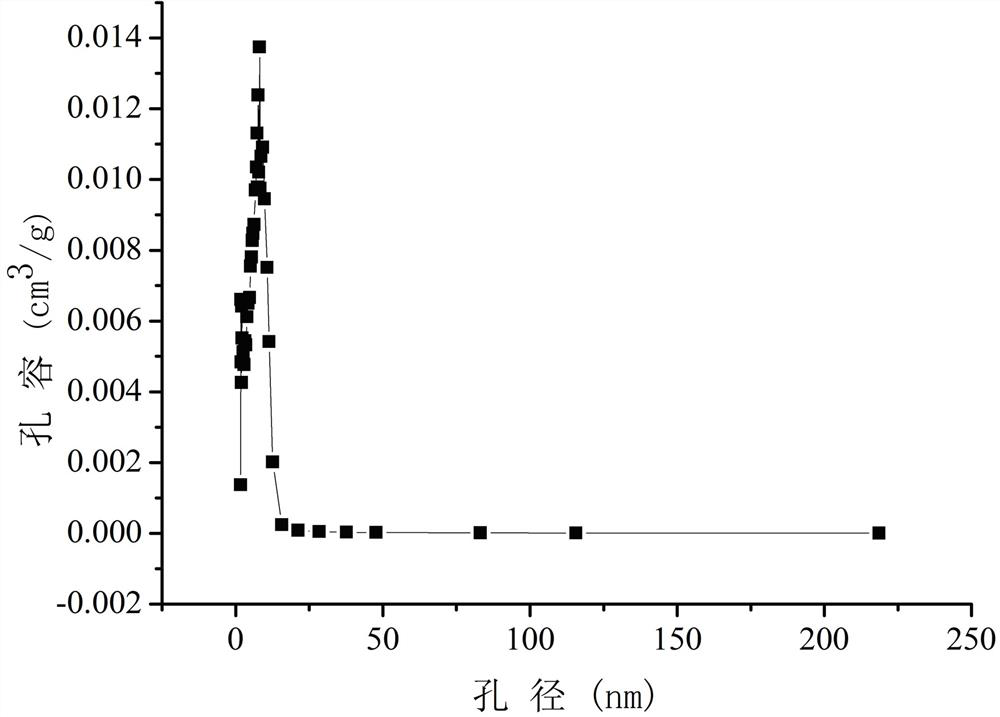

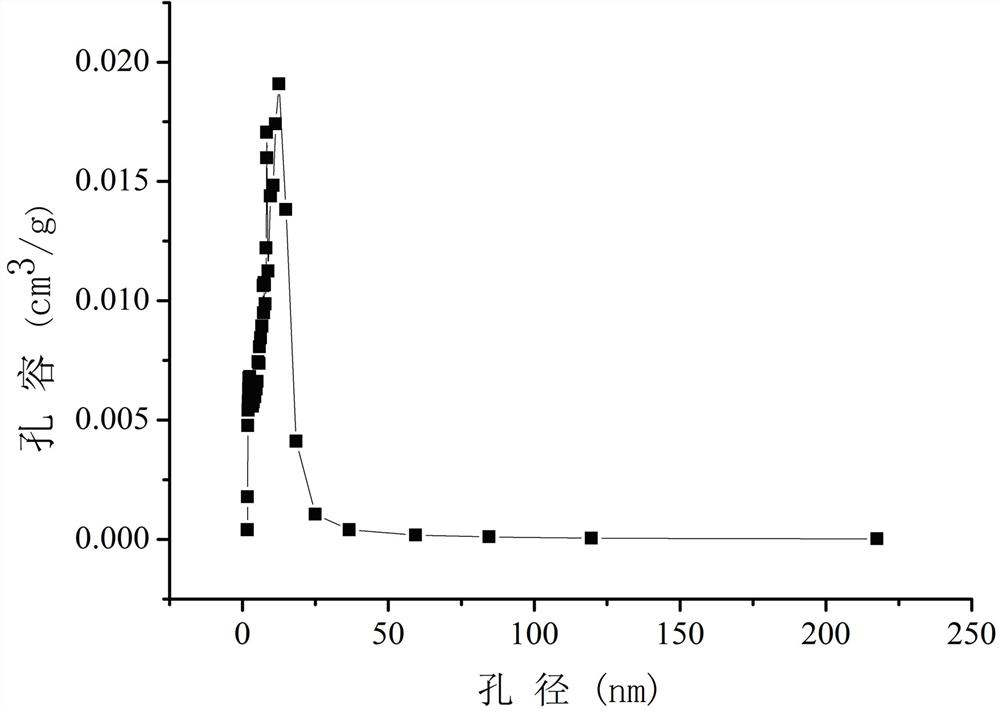

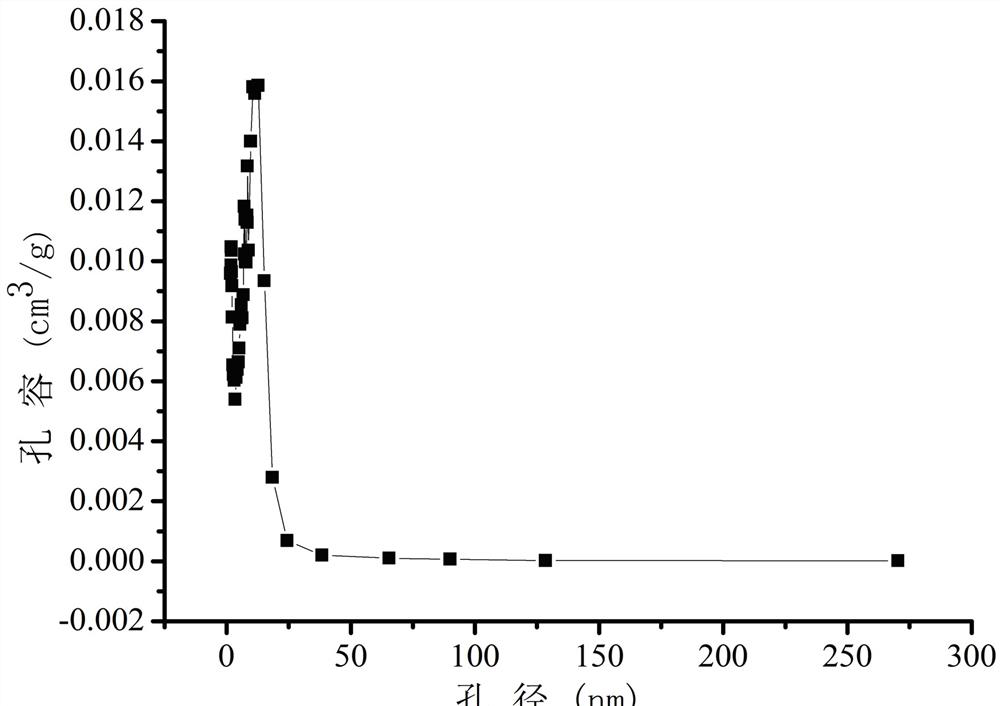

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com