Alkene co-cracking catalyst and alkene mixed catalytic cracking method

A catalyst and co-cracking technology, applied in the field of alkene co-cracking catalyst and its alkene mixed catalytic cracking, can solve the problems of catalyst loss, high coking amount, low total conversion rate and low propylene selectivity yield, etc., so as to improve the adsorption capacity , Low coking amount, and the effect of improving the total conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

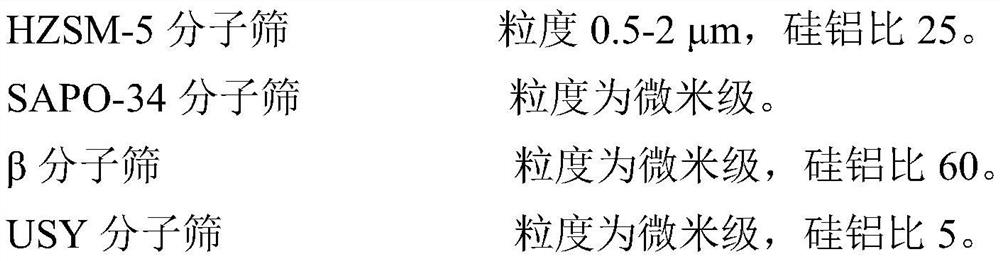

[0061] (1) Handling of active ingredients

[0062] Mix the HZSM-5 molecular sieve and the USY molecular sieve according to the mass ratio of 3:1 to obtain the composite molecular sieve, and then add the composite molecular sieve to the NaOH solution with a concentration of 0.4mol / L and a temperature of 90°C, according to the mass ratio of the composite molecular sieve to NaOH: Mix 1:6, wash the composite molecular sieve to neutrality, then dry at 120°C for 12h and calcinate at 540°C for 2h. Then add the composite molecular sieve into the 1mol / L ammonium nitrate solution, mix according to the mass ratio of the composite molecular sieve and the ammonium nitrate solution at 1:10, exchange the ammonium at 90°C for 4 hours, then wash until neutral, and then in sequence Drying at 120°C for 12h and calcining at 540°C for 4h yields an alkali-treated composite molecular sieve.

[0063] Mix the alkali-treated composite molecular sieve with the composite metal oxide at a mass ratio of 4...

Embodiment 2

[0071] The catalyst was prepared according to the same process as in Example 1, except that the composition of the composite molecular sieve was mixed according to the mass ratio of HZSM-5:USY:β:SAPO-34=25:7:5:3.

[0072] All the other operations are the same as in Example 1.

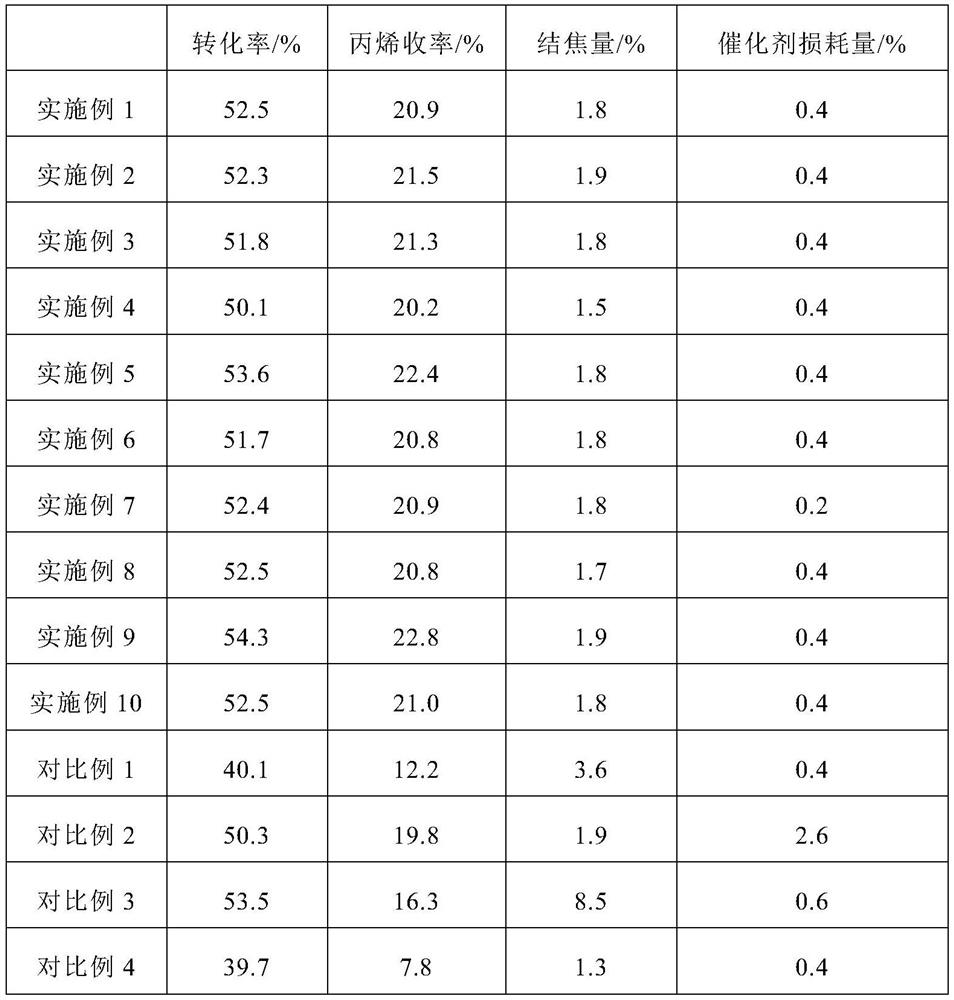

[0073] The catalytic effect evaluation experiment of the catalyst is the same as in Example 1, and the results are shown in Table 2.

Embodiment 3

[0075] The catalyst was prepared according to the same process as in Example 1, except that the composition of the composite molecular sieve was mixed according to the mass ratio of HZSM-5:USY:SAPO-34=27:9:4.

[0076] All the other operations are the same as in Example 1.

[0077] The catalytic effect evaluation experiment of the catalyst is the same as in Example 1, and the results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com