Preparation method of corrosion-resistant sliding bearing lubricant for magnetic drive pump

A sliding bearing, corrosion-resistant technology, used in the field of lubricants, can solve the problems of heat can not be quickly taken away, more oil leakage, poor bearing lubrication, etc., to achieve good chemical inertness and non-flammability, low shear strength, Good adhesion and continuity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

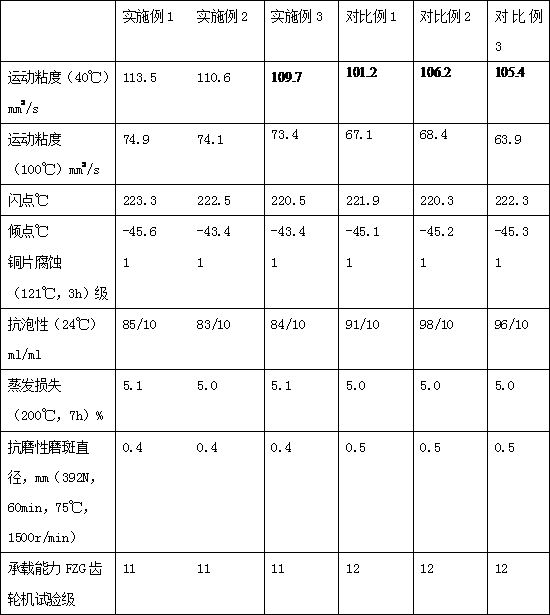

Examples

Embodiment 1

[0022] A preparation method of a corrosion-resistant sliding bearing lubricant for a magnetic pump, a preparation method of a corrosion-resistant sliding bearing lubricant for a magnetic pump, comprising the following steps: (1) weighing the following raw materials in parts by weight: base oil 102 15 parts of thickener, 5 parts of solid lubricant, 0.5 parts of structural stabilizer, 5 parts of extreme pressure antiwear agent, 3 parts of antioxidant, 1 part of tackifier; (2) Mix 2 / 3 of the base oil 1. Put the thickener into the reaction kettle according to the mass, stir and heat to 90~120°C, and keep it for 60 minutes; (3) Add a certain amount of water into the reaction kettle, continue to stir and react, and the amount of water added is the weight of the thickener 15%, the temperature is controlled at 140°C, and the reaction time is controlled at 30 minutes; (4) Heated to 220°C for high-temperature refining, and the reaction time is controlled at 20 minutes; (5) Add the remain...

Embodiment 2

[0024] A method for preparing a corrosion-resistant sliding bearing lubricant for a magnetic pump, comprising the following steps: (1) Weighing the following raw materials in parts by weight: 95 parts of base oil, 5 parts of thickener, 0.5 parts of solid lubricant, structure 0.1 parts of stabilizer, 4.5 parts of extreme pressure antiwear agent, 2.5 parts of antioxidant, 0.8 parts of tackifier;

[0025] (2) Put 2 / 3 of the base oil and thickener into the reactor by mass, stir and heat to 90~120°C, and keep it for 40~min; (3) Add a certain amount of water into the reactor, Continue to stir and react, wherein the amount of water added is 8% of the mass of the thickener, the temperature is controlled at 130~140°C, and the reaction time is controlled at 20~30min; (4) Heating to 190°C for high temperature refining, the reaction time is controlled at 10~ 20min; (5) Add the remaining 1 / 3 of the base oil, and add solid lubricants, tackifiers, structural stabilizers, and antioxidants for...

Embodiment 3

[0027] A method for preparing a corrosion-resistant sliding bearing lubricant for a magnetic pump, comprising the following steps: (1) Weighing the following raw materials in parts by weight: 102 parts of base oil, 15 parts of thickener, 5 parts of solid lubricant, structure 0.5 parts of stabilizer, 5 parts of extreme pressure antiwear agent, 3 parts of antioxidant, 1 part of tackifier; (2) Put 2 / 3 of base oil and thickener into the reaction kettle by mass, stir and heat to 90°C and keep it for 40~60min; (3) Add a certain amount of water to the reaction kettle and continue to stir the reaction, wherein the amount of water added is 8% of the mass of the thickener, the temperature is controlled at 130°C, and the reaction time is controlled at 20min ; (4) Heat to 190~220°C for high temperature refining, and the reaction time is controlled at 10 minutes; (5) Add the remaining 1 / 3 of the base oil, and add solid lubricants, tackifiers, structural stabilizers, and antioxidants Carry ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com