Power battery pack fatigue life calculation method

A power battery pack, fatigue life technology, applied in calculation, computer-aided design, design optimization/simulation, etc., can solve the problems of actual working condition deviation, excluding torsional strength, etc., to reduce simulation errors, improve performance, and improve Effects on Modeling Efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

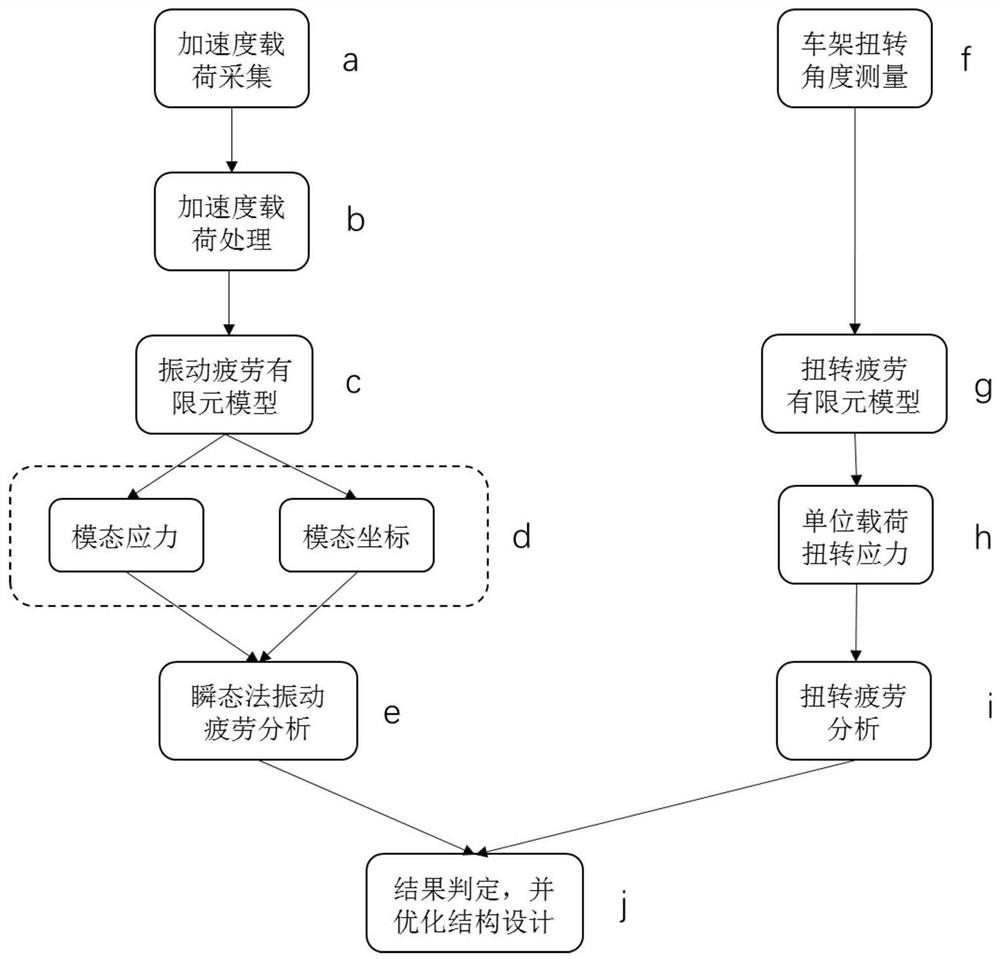

[0059] Embodiment 1: as figure 1 As shown, a method for calculating the fatigue life of a power battery pack includes the following steps:

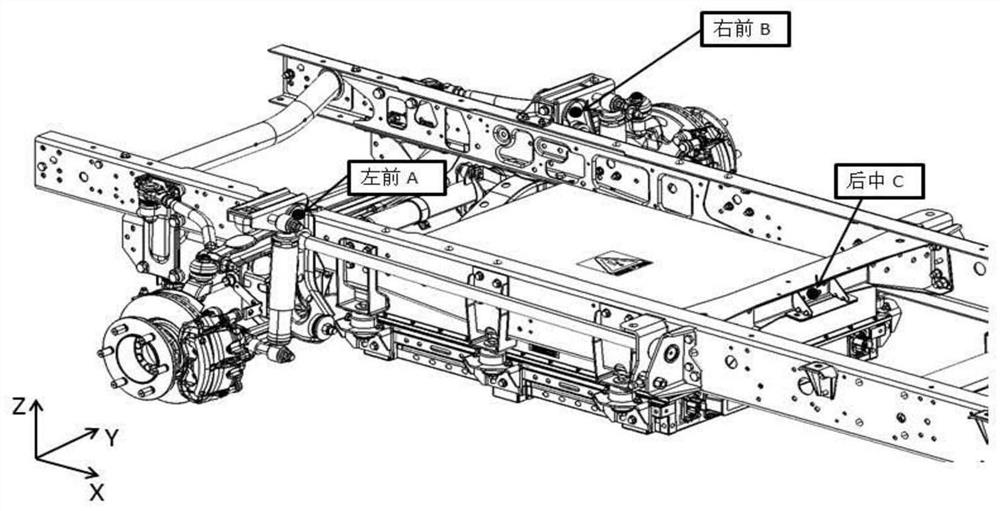

[0060] a. Acceleration load collection: Arrange three three-way acceleration sensors on the beam near the power battery pack. The acceleration sensor model is: PCB 356A26, and collect the acceleration load spectrum of the power battery pack on the typical road surface of the test site;

[0061] b. Acceleration load processing: check the data rationality of the measured acceleration load spectrum, select relevant channels for filtering, and eliminate low frequency and high frequency parts that have little effect on fatigue strength;

[0062] c. Establish a vibration fatigue finite element model: establish a finite element model of the frame truncated belt power battery pack, use shell elements to simulate the solder joints and welds in the key areas of the power battery pack, and perform constrained modal analysis to judge whether the mode...

example 1

[0093] Example 1: The node number 403826 on the welding seam of the power battery pack has a loss value of 1.6e for one cycle on the No. 1 Belgian road -5 , the loss value of one cycle on No. 2 shortwave road is 2.2e -6 , then the total damage value of node number 403826 is:

[0094] D. v =C 1 D. 1 +C 2 D. 2 ;

[0095] D. v : The total damage value on each unit of the power battery pack;

[0096] C 1 : Number of cycles on Belgian pavement No. 1, C 1 =20440;

[0097] C 2 : Number of cycles on No. 2 shortwave road, C 2 =4088;

[0098] D. v =20440×1.6e -5 +4088×2.2e -6 =0.33>0.2 does not meet the requirements.

example 2

[0099] Example 2: The loss value of the node number 1905295 on the welding seam of the power battery pack for one cycle on the No. 1 Belgian road is 2.81e -6 , the loss value of one cycle on No. 2 shortwave road is 1.05e -6 , then the total damage value of node number 1905295 is:

[0100] D. v =C 1 D. 1 +C 2 D. 2 ;

[0101] D. v : The total damage value on each unit of the power battery pack;

[0102] C 1 : Number of cycles on Belgian pavement No. 1, C 1 =20440;

[0103] C 2 : Number of cycles on No. 2 shortwave road, C 2 =4088;

[0104] D. v =20440×2.81e -6 +4088×1.05e -6 =0.062<0.2, meeting the requirements.

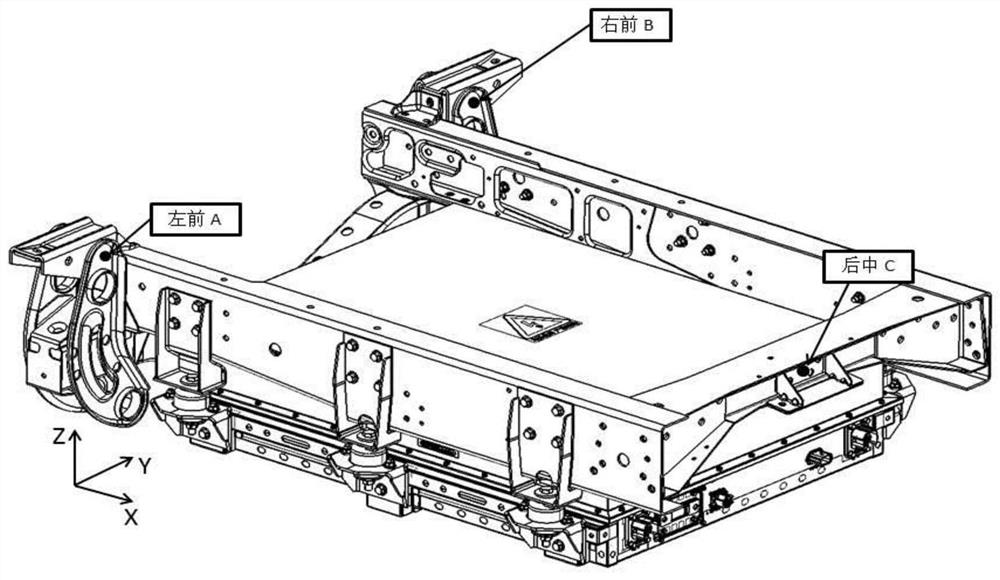

[0105] The limit torsion angle of the vehicle in step f is measured under quasi-static conditions. The working condition is that the left front wheel is raised by 150 mm, and the right rear wheel is raised by 150 mm. The measured torsion angle of the front and rear axles of the frame is θ=0.8°.

[0106] like Figure 9 As shown, the finite element mod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com