Inorganic lead-free double perovskite thin film, solar cell and preparation method thereof

A lead-free double perovskite and double perovskite technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of battery device performance degradation, incompleteness, composition deviation, etc., and achieve good photoluminescence response, The effect of high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

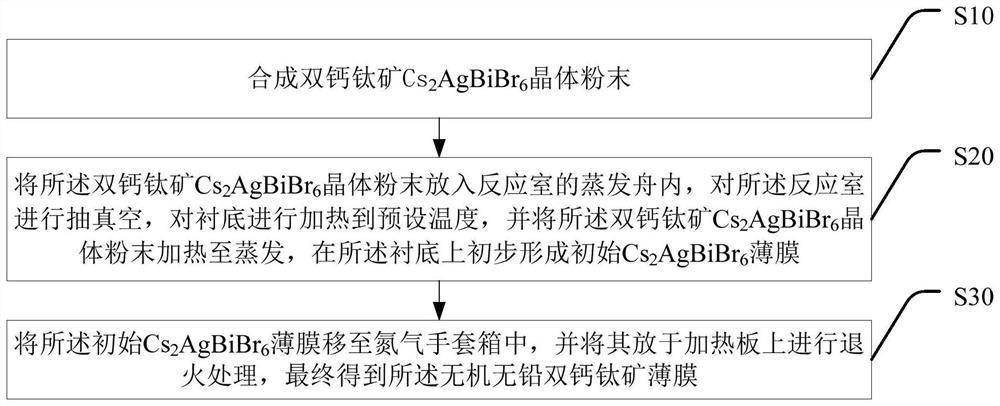

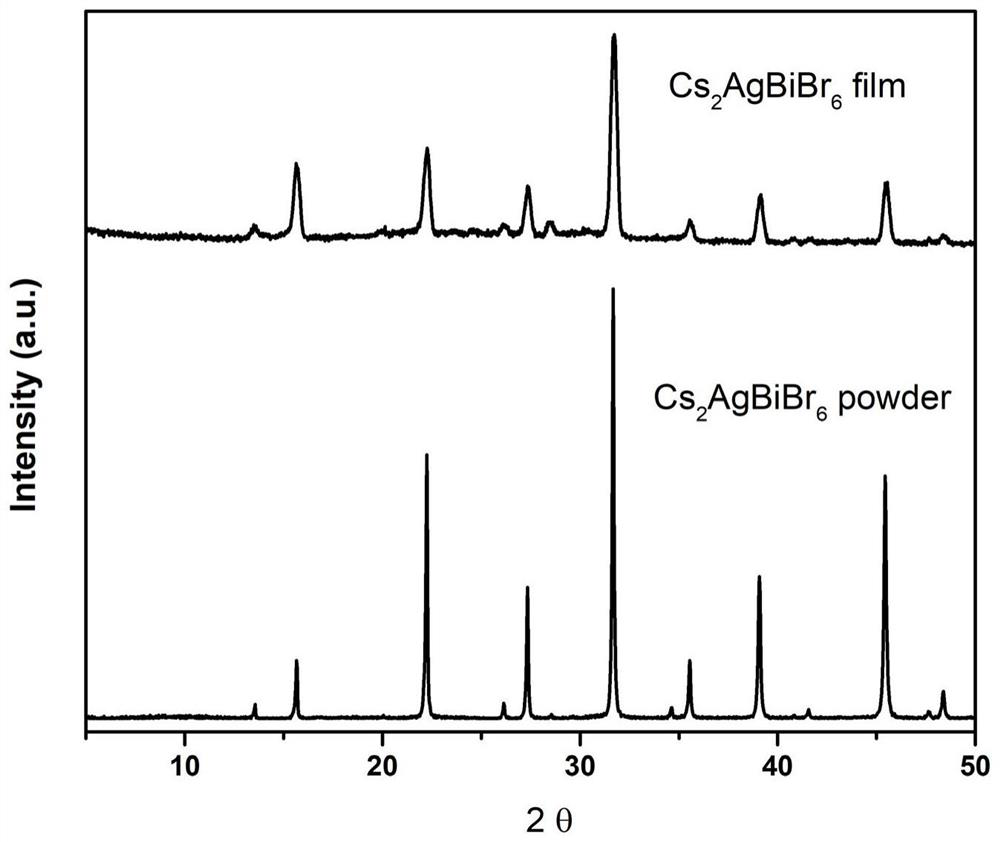

[0051] In this example, FTO glass was used as the substrate, and double perovskite Cs with smooth, dense, high crystallinity, good photoluminescence response and ideal stoichiometric ratio was prepared by vacuum single-source thermal evaporation method. 2 AgBr 6 film.

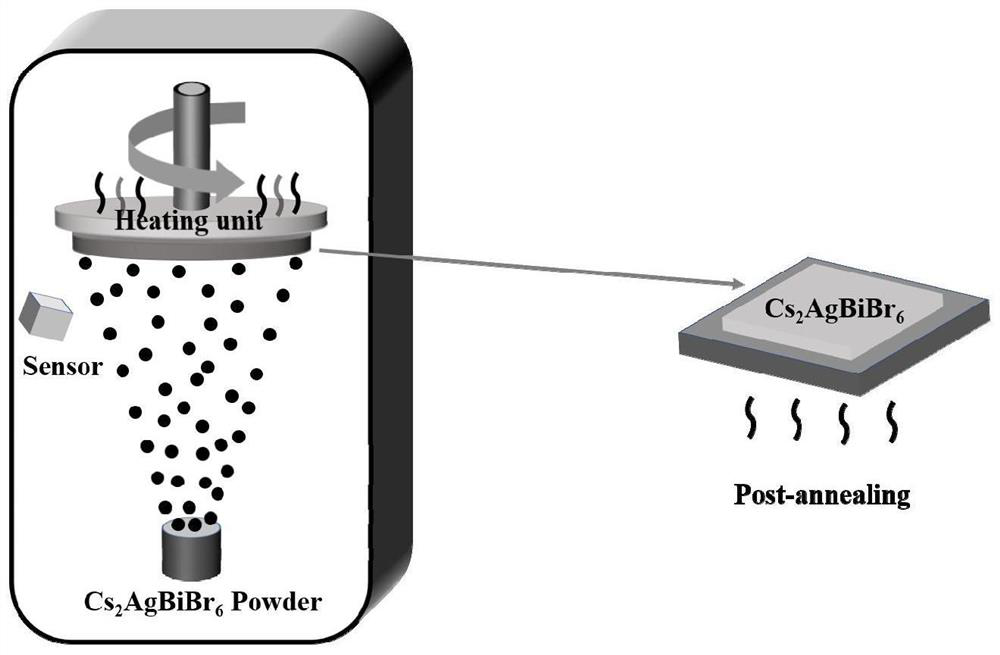

[0052] The synthesized Cs 2 AgBr 6 powder into the figure 2 Cs is directly heated in the vacuum single-source thermal evaporation device shown 2 AgBr 6 powder, the powder is vaporized and deposited directly on the FTO glass substrate to form Cs 2 AgBr 6 film. Its specific preparation process is as follows:

[0053] First, clean the FTO glass substrate and weigh 0.40g Cs 2 AgBr 6 powder, put the powder into the evaporation boat, the distance between the substrate and the evaporation source is 25cm, and vacuumize the reaction chamber until the vacuum degree reaches 5.0×10 -4 After Pa, heat the substrate to 100°C, adjust the substrate speed to 20r / min, then turn on the evaporation power supply, gradual...

Embodiment 2

[0059] In this embodiment, the double perovskite thin-film solar cell adopts a flat solar cell structure such as: FTO / cl-TiO 2 / Cs 2 AgBr 6 / Spiro-OMeTAD / Ag, the FTO glass was cleaned first, and the dense TiO 2 Spin-coat on the FTO glass substrate (3000r / 30s), put it in a muffle furnace for sintering at 450°C for 1 hour, cool down to room temperature for later use; 2 The substrate of the film is transferred to the reaction chamber of the vacuum single-source thermal evaporation device, adopting the same Cs as in Example 1 2 AgBr 6 Thin film preparation method on dense TiO 2 Preparation of Cs on film 2 AgBr 6 film; then in Cs 2 AgBr 6 Spiro-OMeTAD (3000r / 30s) was spin-coated on the film, and finally the Ag electrode was evaporated to form a device structure of FTO / cl-TiO 2 / Cs 2 AgBr 6 / Spiro-OMeTAD / Ag solar cells. The performance of the solar cell prepared in this embodiment is as follows:

[0060] 1. Under AM1.5 simulated sunlight conditions, the double perovskit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com