Ultraviolet light-emitting diode epitaxial wafer and manufacturing method thereof

A technology for light-emitting diodes and a manufacturing method, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of increased V-shaped pit density, weakened carrier confinement capability, and reduced potential barrier height.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to make the purpose, technical solution and advantages of the present disclosure clearer, the implementation manners of the present disclosure will be further described in detail below in conjunction with the accompanying drawings.

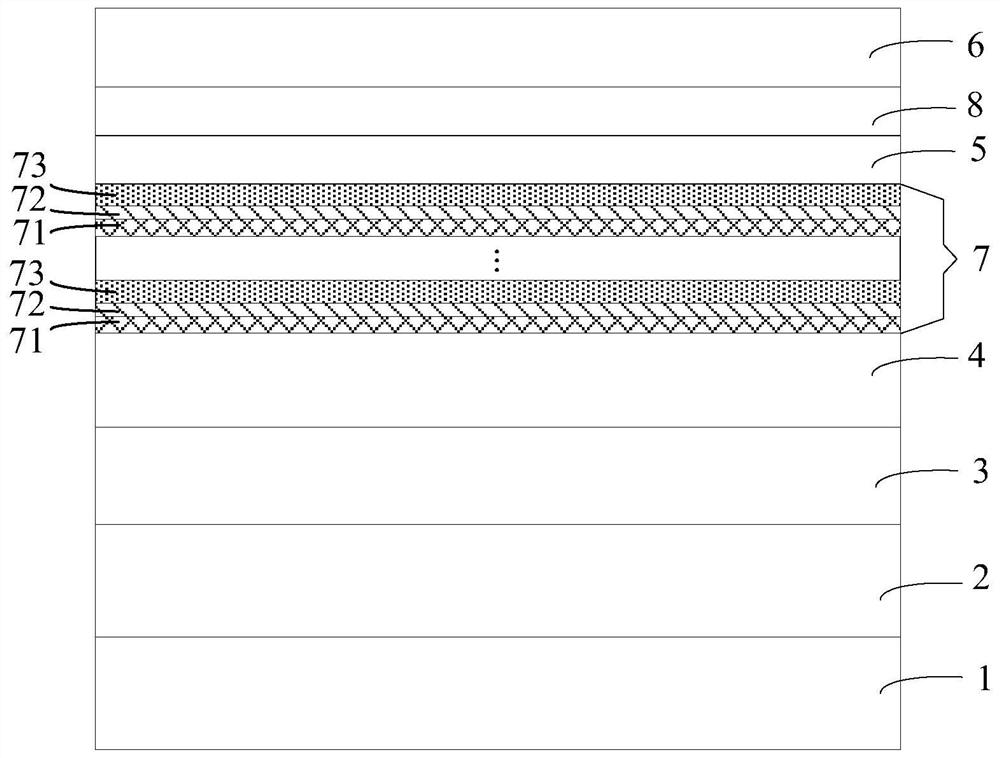

[0028] figure 1 It is a schematic structural diagram of an ultraviolet light-emitting diode epitaxial wafer provided by an embodiment of the present disclosure, as shown in figure 1 As shown, the ultraviolet light emitting diode epitaxial wafer includes a substrate 1 , a buffer layer 2 , an undoped AlGaN layer 3 , an N-type layer 4 , an active layer 5 and a P-type layer 6 stacked on the substrate 1 in sequence.

[0029] The UV light emitting diode further includes a stress release layer 7 disposed between the N-type layer 4 and the active layer 5 , and the stress release layer 7 includes a first sub-layer 71 , a second sub-layer 72 and a third sub-layer 73 stacked in sequence. The first sublayer 71 is a low temperature InGaN subla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com