Method for preparing rice-straw coarse feed

A technology for rice straw and roughage, which is applied in the field of preparation of rice straw roughage, can solve the problems of low nutrient utilization rate, difficulty in feeding, poor palatability, etc., and can solve the shortage of forage grass, improve physical and chemical properties, and satisfy taste and nutrition. effect of demand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

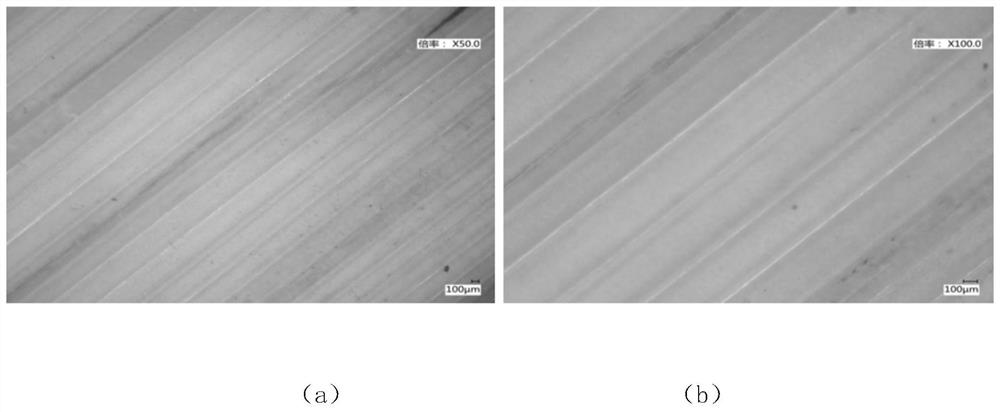

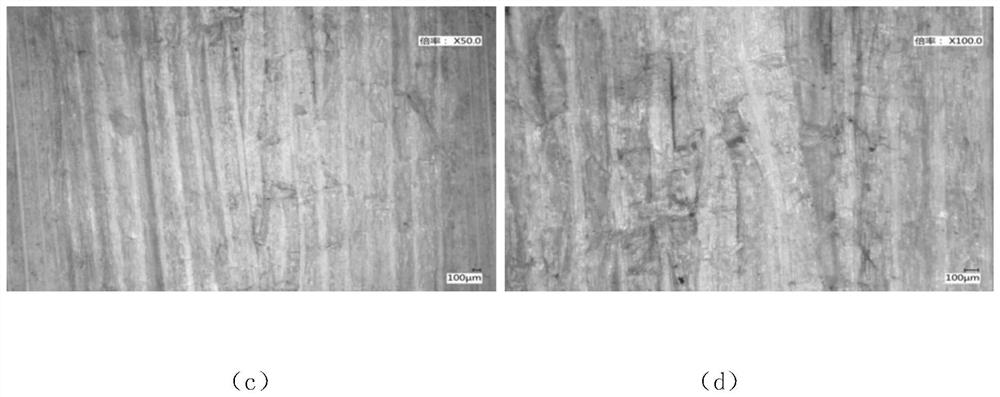

Image

Examples

Embodiment 1

[0024] (1) In the Shenyang rice area, the rice straw after being fully fed into the rice harvester to harvest the grains is used as raw material. If the straw is not harvested in time and dried, the moisture content will drop to 40% (crude protein 8%, crude fiber 55%), It is necessary to adjust the moisture content to about 60% for collection;

[0025] (2) Dissolve the bacterium-enzyme compound preparation in an appropriate amount of brown sugar that has been boiled and inactivated, and then the cooling temperature does not exceed 40°C in warm water; the mass ratio of the preparation to the sugar is 1:5, and the preparation and the sugar water are stirred evenly and then sealed for 3 days to activate the starter. use;

[0026] (3) Dilute the mixture of sugar water preparation with water 1:10, add it to the liquid storage box of the micro-storage baler, and use the rice straw micro-storage baler to carry out straw picking, fermentation agent spraying, bundling, and plastic seal...

Embodiment 2

[0031] (1) With the Shenyang rice field, the rice straw that is pulverized after fully feeding the rice harvester to harvest the grain is used as raw material, and the moisture content of the raw material is 65% (crude protein 9%, crude fiber 55%) to be collected;

[0032] (2) Dissolve the bacterium-enzyme compound preparation in an appropriate amount of brown sugar that has been boiled and inactivated, then the cooling temperature does not exceed 40°C in warm water; the mass ratio of the preparation to the sugar is 1:4, and the preparation and sugar water are stirred evenly and sealed for 3 days to activate the starter. use;

[0033] (3) Dilute the mixture of sugar and water preparation with water 1:8, add it to the liquid storage box of the micro-storage baler, and use the rice straw micro-storage baler to carry out straw picking, fermentation agent spraying, bundling, and plastic sealing operations; straw feeding speed 48kg / min, starter spraying speed 2.0L / min, round bale d...

Embodiment 3

[0038] (1) With the Shenyang rice field, the rice straw that is pulverized after fully feeding the rice harvester to harvest the grains is used as raw material, and the moisture content of the raw material is 50% (crude protein 9%, crude fiber 57%) to be collected;

[0039] (2) Dissolve the bacterium-enzyme compound preparation in warm water that has been boiled and inactivated with an appropriate amount of brown sugar, and the cooling temperature does not exceed 40°C; the mass ratio of the preparation to the sugar is 1:6, and the preparation and the sugar water are stirred evenly and sealed for 3 days to activate the starter use;

[0040] (3) Dilute the sugar water preparation mixture with water at a ratio of 1:15, add it to the liquid storage box of the micro-storage baler, and use the rice straw micro-storage baler to carry out straw picking, fermentation agent spraying, bundling, and plastic sealing operations; straw feeding speed 48kg / min, starter spraying speed 3.4L / min,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com