PtCo nano-alloy modified Co3O4-SiO2 flower-like multistage composite material and preparation method thereof

A technology of co3o4-sio2 and composite materials, applied in the direction of metal/metal oxide/metal hydroxide catalysts, chemical instruments and methods, carbon compounds, etc., can solve the problem that active substances and catalytic substrates cannot be fully contacted and cannot be effectively Inhibit the problems of agglomeration and sintering of active materials, not easy structural stability, etc., and achieve the effects of stable product morphology, convenient and simple product processing, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

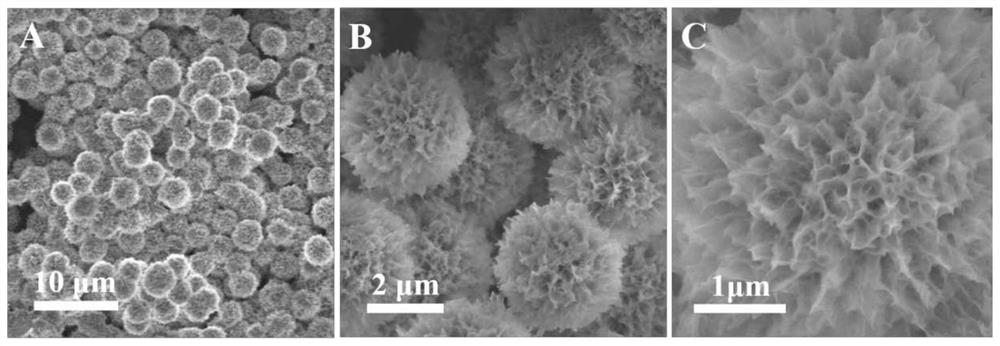

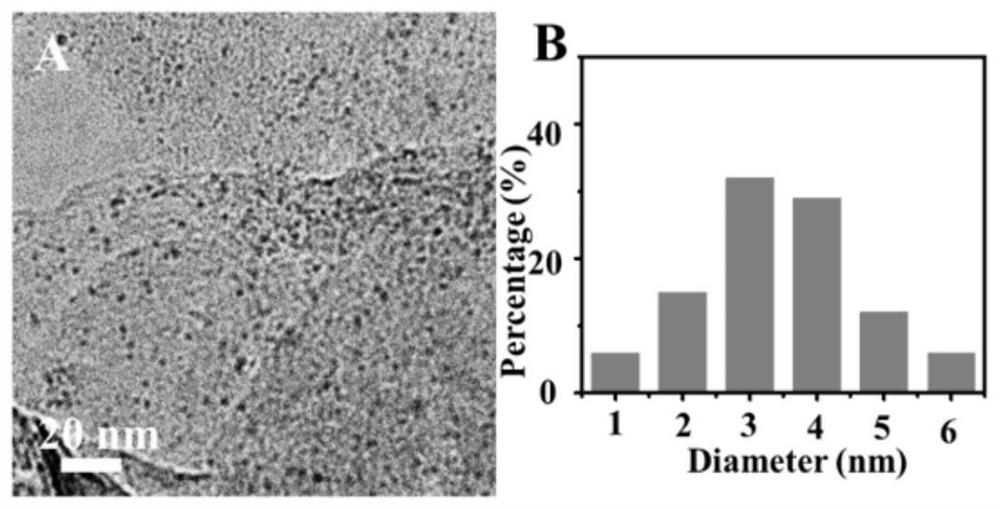

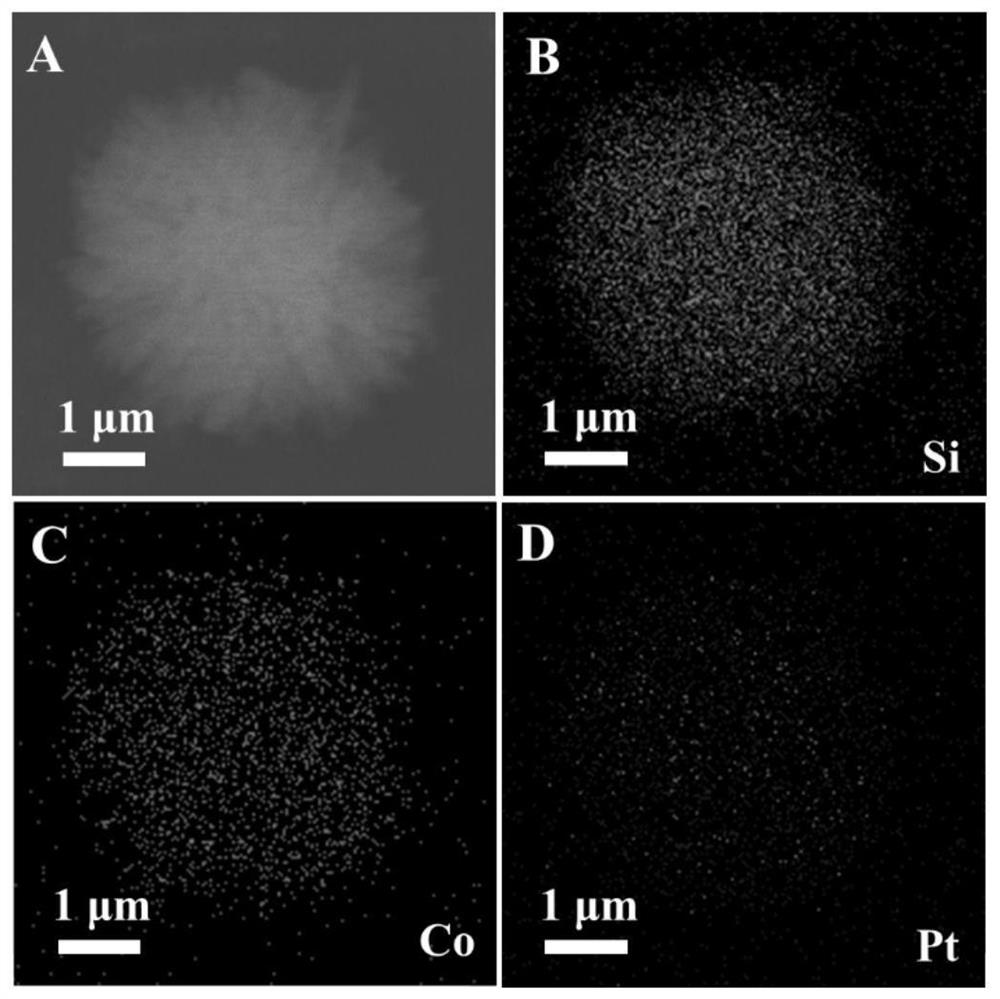

[0065] 1)Co 3 o 4 -SiO 2 Synthesis steps of composite materials:

[0066] Step 1: Weigh a certain mass of CuCl respectively 2 ·6H 2 O and CoCl 2 ·6H 2 O, configured at a concentration of 5 mM CuCl 2 aqueous solution and 5mM CoCl 2 aqueous solution. The silicon wafer was pretreated, cut into small square pieces of 1cm*1cm, and then ultrasonically washed with ethanol and acetone alternately until the solution was clear, then ultrasonicated three times with deionized water and stored in deionized water for later use.

[0067] The second step: add 5mL of CuCl to the 30mL polytetrafluoroethylene high temperature reaction kettle with a pipette gun 2 aqueous solution and 15 mL of CoCl 2 Aqueous solution, then add 200mg of urea and a piece of treated silicon chip, stir to dissolve.

[0068] Step 3: Cover and seal the reaction kettle and place it in an electric heating constant temperature blast drying oven at a temperature of 1°C min -1 The heating rate was increased from ...

Embodiment 2

[0083] 1)Co 3 o 4 -SiO 2 Synthesis steps of composite materials:

[0084] Step 1: Weigh a certain mass of CuCl respectively 2 ·6H 2 O and CoCl 2 ·6H 2 O configured as CuCl at a concentration of 5 mM 2 aqueous solution and 5mM CoCl 2 aqueous solution. The silicon wafer was pretreated, cut into small square pieces of 1cm*1cm, and then ultrasonically washed with ethanol and acetone alternately until the solution was clear, then ultrasonicated three times with deionized water and stored in deionized water for later use.

[0085] The second step: add 5mL of CuCl to the 30mL polytetrafluoroethylene high temperature reaction kettle with a pipette gun 2 aqueous solution and 15 mL of CoCl 2 Aqueous solution, then add 200mg of urea and a piece of treated silicon chip, stir to dissolve.

[0086] Step 3: Cover and seal the reaction kettle and place it in an electric heating constant temperature blast drying oven at a temperature of 1°C min -1 The heating rate is increased from...

Embodiment 3

[0096] 1)Co 3 o 4 -SiO 2 Synthesis steps of composite materials:

[0097] Step 1: Weigh a certain mass of CuCl respectively 2 ·6H 2 O and CoCl 2 ·6H 2 O, configured at a concentration of 5 mM CuCl 2 aqueous solution and 5mM CoCl 2 aqueous solution. The silicon wafer was pretreated, cut into small square pieces of 1cm*1cm, and then ultrasonically washed with ethanol and acetone alternately until the solution was clear, then ultrasonicated three times with deionized water and stored in deionized water for later use.

[0098] The second step: add 5mL of CuCl to the 30mL polytetrafluoroethylene high temperature reaction kettle with a pipette gun 2 aqueous solution and 15 mL of CoCl 2 Aqueous solution, then add 300mg ~ 500mg of urea and a piece of processed silicon chip, stir to dissolve.

[0099] Step 3: Cover and seal the reaction kettle and place it in an electric heating constant temperature blast drying oven at a temperature of 1°C min -1 The heating rate was incre...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com