Anti-cracking concrete and preparation method thereof

A concrete and anti-cracking technology, which is applied in the field of concrete, can solve the problems of concrete structure collapse and poor durability, and achieve the effects of improving cracking resistance, reducing alkali content, and inhibiting alkali-aggregate reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] A kind of anti-cracking concrete obtained by stirring and mixing the following raw materials in parts by mass,

[0045] 34kg of cement,

[0046] Aggregate 26kg,

[0047] 55kg of water,

[0048] Fly ash 13kg,

[0049] Anti-cracking auxiliary agent, wherein the anti-cracking auxiliary agent includes 20kg of amylose, 30kg of calcium formate and 13kg of acrylic acid, and the particle size of the anti-cracking auxiliary agent is 4mm.

[0050] Wherein the preparation steps of anti-cracking auxiliary agent are as follows,

[0051] W1: Spray granulation after mixing amylose with acrylic acid and water, and obtain starch balls in 20 minutes:

[0052] W2: Mix calcium formate with water to obtain a paste, spray it on the outside of the starch ball, and obtain an anti-cracking additive after drying.

[0053] A crack-resistant concrete and a preparation method thereof, comprising the steps of:

[0054] W1: Mix cement, water and aggregate in a small concrete mixer with a rated ...

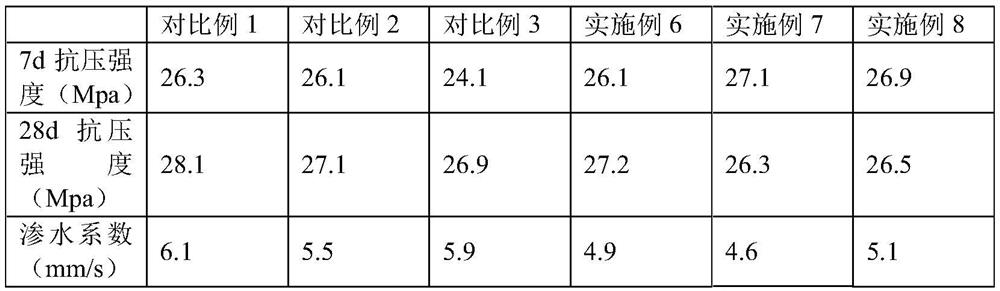

Embodiment 6

[0074] An anti-cracking concrete, based on the basis of Example 1, the starch is amylopectin, and the amount of amylopectin is the same as that of amylose in Example 1.

Embodiment 7

[0076] A kind of anti-cracking concrete, based on the basis of embodiment 1, triethanolamine is selected as the early strength agent, and the consumption of triethanolamine is the same as that of calcium formate in embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com