High-ductility repair mortar with self-healing function and preparation method thereof

A high ductility and functional technology, applied in the field of reinforcement and repair mortar, can solve the problem that cement-based composite materials do not have self-healing properties, and achieve the effect of improving the repair level, improving the strength and ductility of mortar, and ensuring durability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

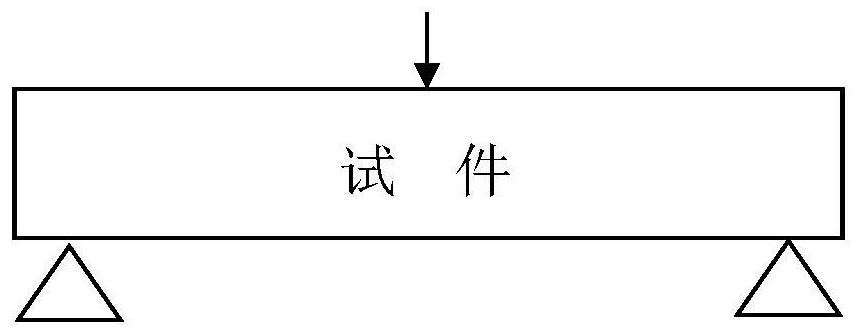

Image

Examples

Embodiment 1

[0033] A high-ductility repair mortar with self-healing function is prepared according to the following steps:

[0034] 1) According to the mass ratio of gel material: quartz sand: water: concrete expansion agent: PM109 polycarboxylate superplasticizer: polyvinyl alcohol fiber: 10.37: 4.75: 2.6: 0.0518: 0.02375: 0.1685, weigh the raw materials respectively; Among them, the gel material is P.O.42.5 cement and first-class fly ash, and the first-class fly ash accounts for 58% of the gel material;

[0035] 2) Mix P.O.42.5 cement, first-grade fly ash, quartz sand, PM109 polycarboxylate superplasticizer and concrete expansion agent, and stir for 10 minutes at a speed of 30-50 rpm to make the materials evenly mixed;

[0036] 3) Add water to the homogeneously mixed material obtained in step 2), and stir for 15 minutes at a speed of 30-50 rpm to obtain the base material;

[0037] 4) Under stirring at a speed of 30-50 rpm, put the polyvinyl alcohol fiber into the substrate obtained in ...

Embodiment 2

[0039] A high-ductility repair mortar with self-healing function is prepared according to the following steps:

[0040] 1) According to the mass ratio of gel material: quartz sand: water: concrete expansion agent: PM109 polycarboxylate superplasticizer: polyvinyl alcohol fiber: 10.37: 4.75: 2.6: 0.0518: 0.02375: 0.1800, weigh the raw materials respectively; Among them, the gel material is P.O.42.5 cement and first-class fly ash, and the first-class fly ash accounts for 58% of the gel material;

[0041] 2) Mix P.O.42.5 cement, first-grade fly ash, quartz sand, PM109 polycarboxylate superplasticizer and concrete expansion agent, and stir for 10 minutes at a speed of 30-50 rpm to make the materials evenly mixed;

[0042] 3) Add water to the homogeneously mixed material obtained in step 2), and stir for 15 minutes at a speed of 30-50 rpm to obtain the base material;

[0043] 4) Under stirring at a speed of 30-50 rpm, put the polyvinyl alcohol fiber into the substrate obtained in ...

Embodiment 3

[0045] A high-ductility repair mortar with self-healing function is prepared according to the following steps:

[0046] 1) According to the mass ratio of gel material: quartz sand: water: concrete expansion agent: PM109 polycarboxylate superplasticizer: polyvinyl alcohol fiber: 10.37: 4.75: 2.6: 0.0518: 0.02375: 0.2022, weigh the raw materials respectively; Among them, the gel material is P.O.42.5 cement and first-class fly ash, and the first-class fly ash accounts for 58% of the gel material;

[0047] 2) Mix P.O.42.5 cement, first-grade fly ash, quartz sand, PM109 polycarboxylate superplasticizer and concrete expansion agent, and stir for 10 minutes at a speed of 30-50 rpm to make the materials evenly mixed;

[0048] 3) Add water to the homogeneously mixed material obtained in step 2), and stir for 15 minutes at a speed of 30-50 rpm to obtain the base material;

[0049] 4) Under stirring at a speed of 30-50 rpm, put the polyvinyl alcohol fiber into the substrate obtained in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com