High-efficiency and low-cost sulfate system electrodeposition process for preparing 4N indium

A high-efficiency and low-cost technology, applied in the low-cost sulfate system electrodeposition process, in the high-efficiency field, can solve the problems of difficult to handle toxic exhaust gas, difficult to expand, complex process, etc., to achieve a short preparation period and speed up the reaction. , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

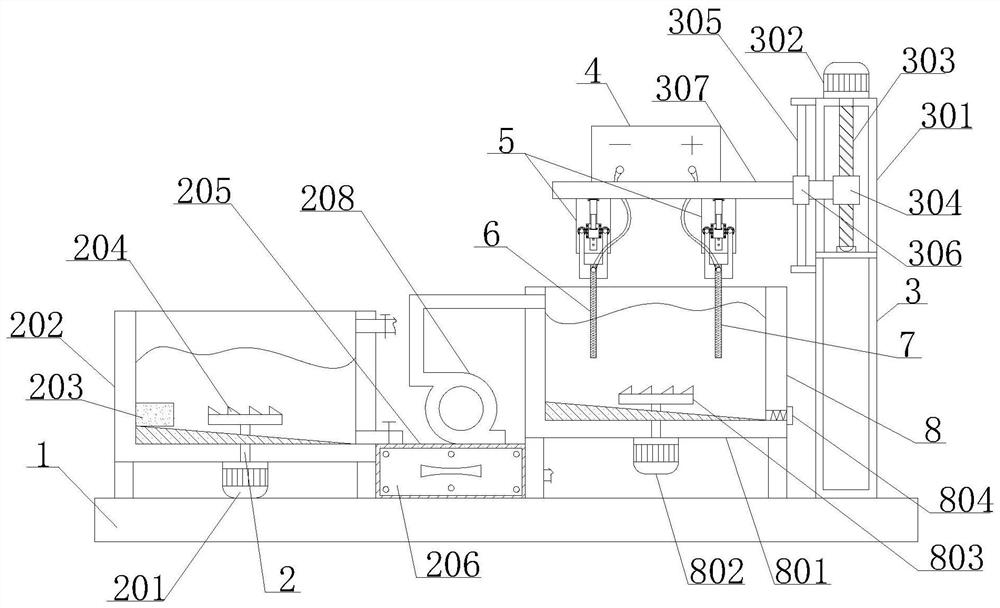

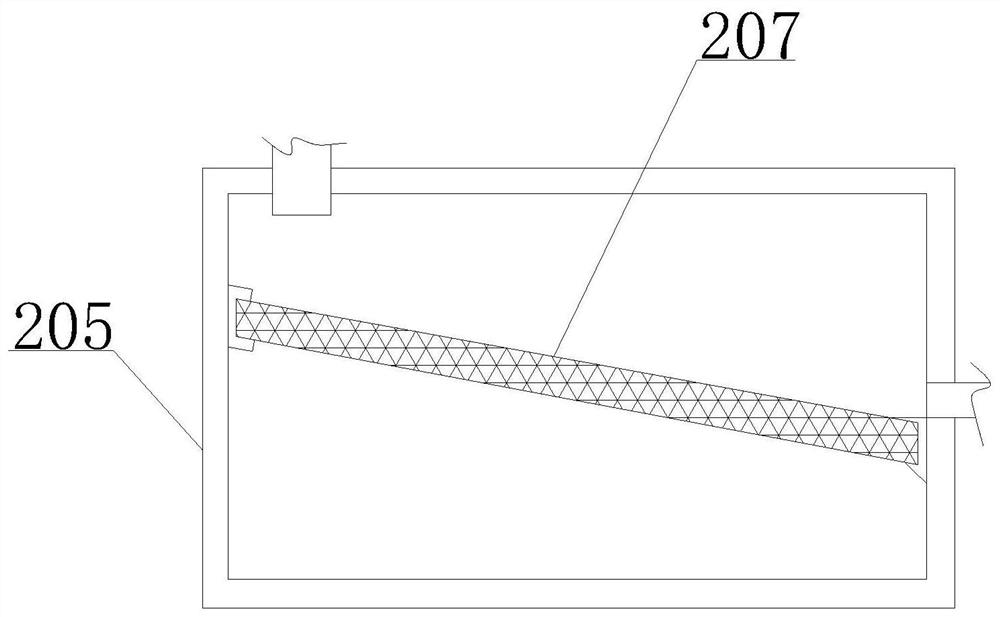

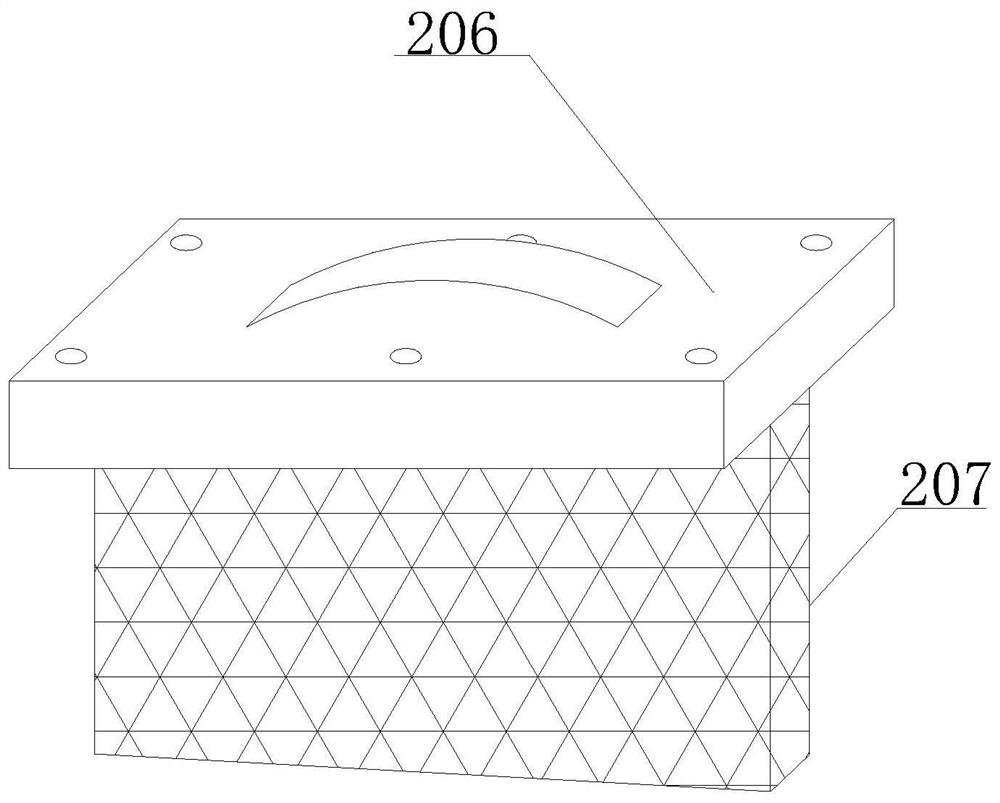

[0037] see Figure 1-7 , the present invention provides a technical solution: a high-efficiency, low-cost sulfate system electrodeposition process for preparing 4N indium, including a bottom plate 1, an electrolyte preparation component 2 is fixedly installed on the top of the bottom plate 1, and the electrolyte preparation component 2 The right side is provided with a lifting device 3, the surface of the lifting device 3 is fixedly installed with a power supply 4, the bottom of the lifting device 3 is provided with a clamping assembly 5, the surface of the clamping assembly 5 is provided with a negative electrode plate 6 and a positive electrode plate 7, and the bottom plate 1 A preparation assembly 8 is fixedly installed on the top.

[0038] The electrolyte mixing assembly 2 includes a mixing motor 201, a mixing box 202 is fixedly installed on the top of the bottom plate 1, a mixing motor 201 is fixedly installed at the bottom of the mixing box 202, and a first stirring blad...

Embodiment 2

[0048] see Figure 1-7 , the present invention provides a technical solution: a high-efficiency, low-cost sulfate system electrodeposition process for preparing 4N indium, including a bottom plate 1, an electrolyte preparation component 2 is fixedly installed on the top of the bottom plate 1, and the electrolyte preparation component 2 The right side is provided with a lifting device 3, the surface of the lifting device 3 is fixedly installed with a power supply 4, the bottom of the lifting device 3 is provided with a clamping assembly 5, the surface of the clamping assembly 5 is provided with a negative electrode plate 6 and a positive electrode plate 7, and the bottom plate 1 A preparation assembly 8 is fixedly installed on the top.

[0049] The electrolyte mixing assembly 2 includes a mixing motor 201, a mixing box 202 is fixedly installed on the top of the bottom plate 1, a mixing motor 201 is fixedly installed at the bottom of the mixing box 202, and a first stirring blad...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap