Casting system for casting production based on Internet of Things

A technology of the Internet of Things and castings, which is applied in the field of castings, can solve the problems of cracks, loss, and easy peeling of the coating on the end face of the castings, and achieve the effects of easy dispersion, high stability, wear resistance and weather resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

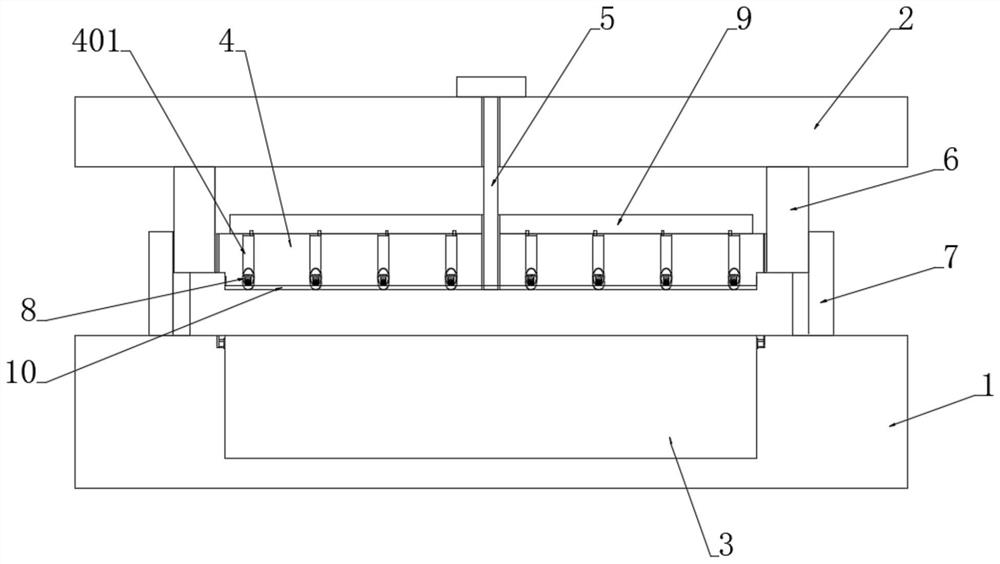

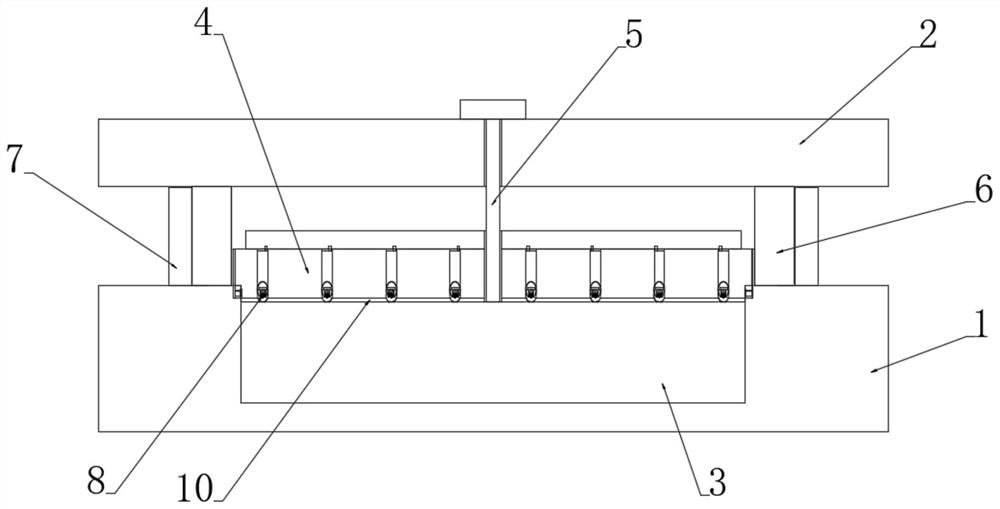

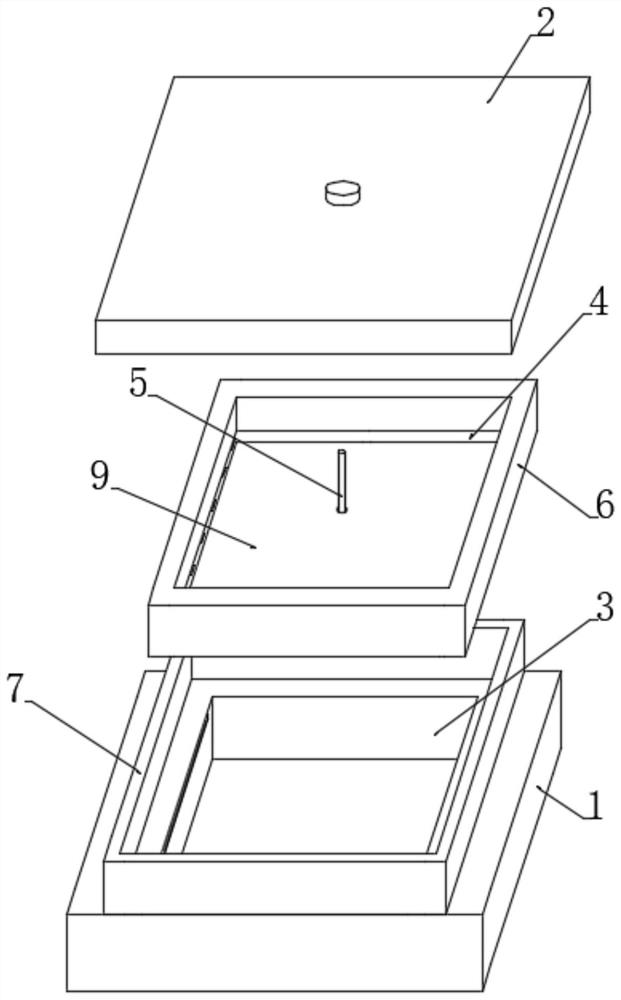

[0043] see Figure 1-4 , a casting system for casting production based on the Internet of Things, a casting mold, a secondary material distribution system, and a pressurization control system. The casting mold includes a lower mold 1 and an upper mold 2. The lower mold 1 has a cavity 3 inside, and the upper mold 2 The bottom end is fixedly connected with an inner limiting platform 6, and the secondary material distribution system includes a distribution platform 4 fixedly connected to the inner side of the inner limiting platform 6, and the bottom end of the distribution platform 4 is fixedly connected with a model 10 matching the cavity 3, and The upper end of the mold 1 is provided with an outer limiting platform 7 which is slidingly embedded and connected with the inner limiting platform 6, and the upper mold 2 is provided with a pouring channel 5 in the middle of the top, and the bottom end of the pouring channel 5 runs through the upper mold 2 and the distribution table 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com