In-furnace de-coking anti-corrosive agent and preparation and use method thereof

A technology of chemicals and boilers, which is applied in the field of flue gas denitrification, can solve the problems of unreasonable distribution ratio of effective components of solvent-based decoking agents, difficulty in obtaining raw materials of solvent-based decoking agents, and complex components of solvent-based decoking agents. Achieve the best decoking effect, wide application range, and improve the effect of structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0022] The preparation method of the decoking and anticorrosion agent in the furnace of the present invention: weigh the content of each component according to the formula, mix and stir after weighing, and at the same time, add the ingredients while stirring at a stirring speed of 400 to 500 rpm. For the required water, the stirring time is 20 to 50 minutes. After it is fully dissolved, it is left to room temperature and put into a container for use.

[0023] Method of use: There are two ways to use the decoking and anticorrosion agent in the furnace of the present invention, which can be used not only when the boiler is running, but also after the boiler stops running. The first method of use, when the boiler is running, put the prepared decoking and anticorrosion agent into the spraying device, and spray according to the combustion situation inside the boiler; the second method of use, after the boiler stops running, put the prepared The decoking and anticorrosion agent is p...

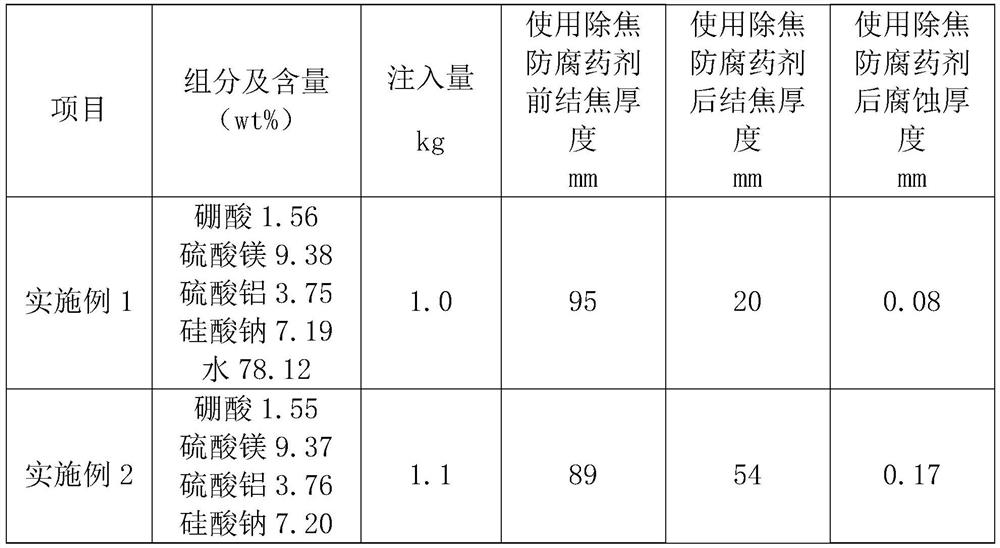

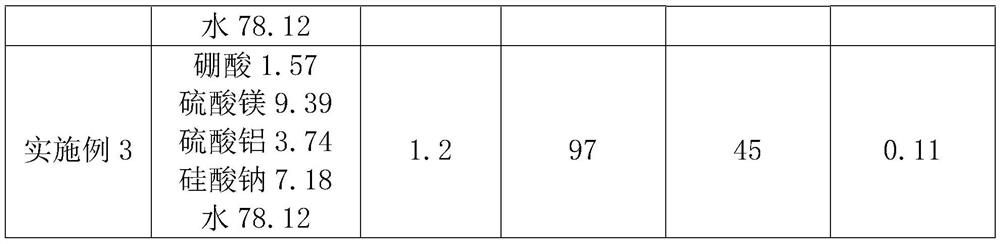

Embodiment 1

[0026] Weigh boric acid 1.56wt% by mass percentage, magnesium sulfate 9.38wt%, aluminum sulfate 3.75wt%, sodium silicate 7.19wt%, then add 78.12wt% water, at a temperature of 36°C at a speed of 450 rpm Stir for 40 minutes to fully dissolve the solute. After placing it at room temperature, take 1.0 kg of the prepared coking and antiseptic agent in the furnace and put it into the spraying device, and spray the coking and antiseptic agent on the coking part inside the boiler through the boiler observation port. . The boiler used in this embodiment is a coal-fired boiler.

Embodiment 2

[0028] Weigh 1.55wt% of boric acid, 9.37wt% of magnesium sulfate, 3.76wt% of aluminum sulfate, 7.20wt% of sodium silicate, and then add 78.12wt% of water. Embodiment 2 is the same as the preparation method and usage method of embodiment 1. The boiler used in this embodiment is a garbage incinerator, and the amount of decoking and anticorrosion agent in the furnace is 1.1kg.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com