Ozone electrolytic bath

An electrolytic cell and ozone technology, applied in the electrolysis process, electrolysis components, electrodes, etc., can solve the problems of unsuitability for industrial-scale mass production, the diamond sheet is easily broken, and the qualified rate of finished products is low. Processing and molding, the effect of improving electrolysis efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

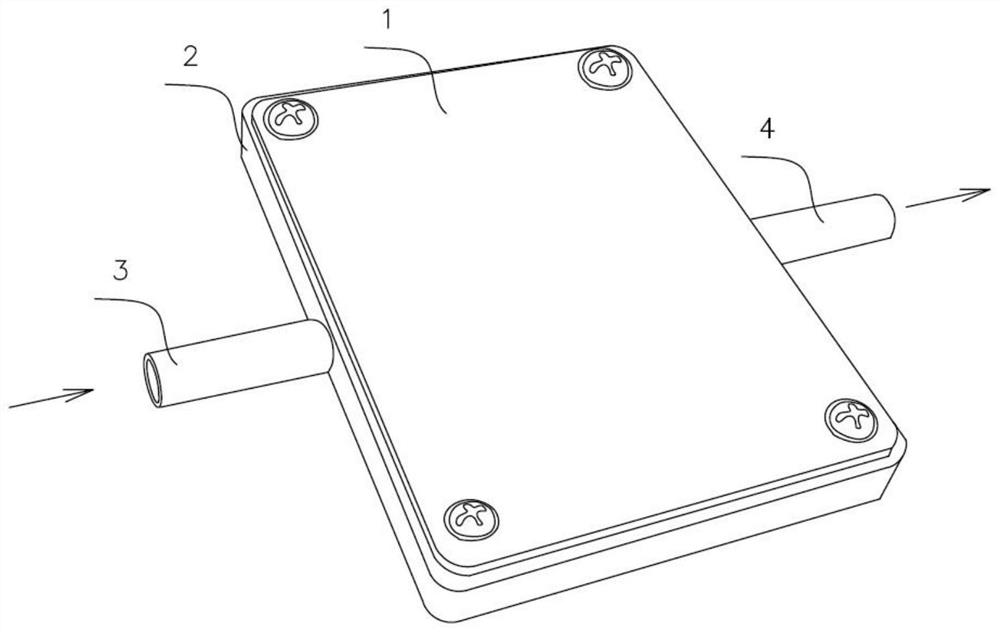

[0032] figure 1 Shows the external structure of the electrolytic cell of the present invention, the first electrode metal sheet 1, the insulating frame 2, and the second electrode metal sheet 12 are fastened by bolts to form an electrolytic cell cavity capable of withstanding water pressure, and the insulating frame 2 is provided with The water inlet 3 and the water outlet 4, the direction of water flow in the electrolytic cell is the direction from the water inlet 3 to the water outlet 4.

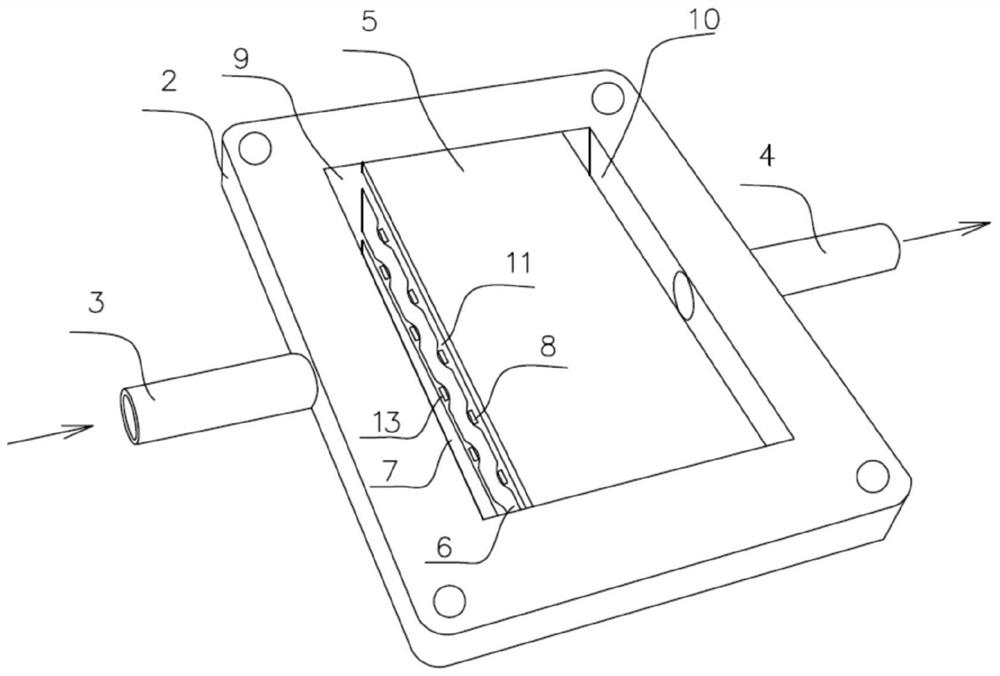

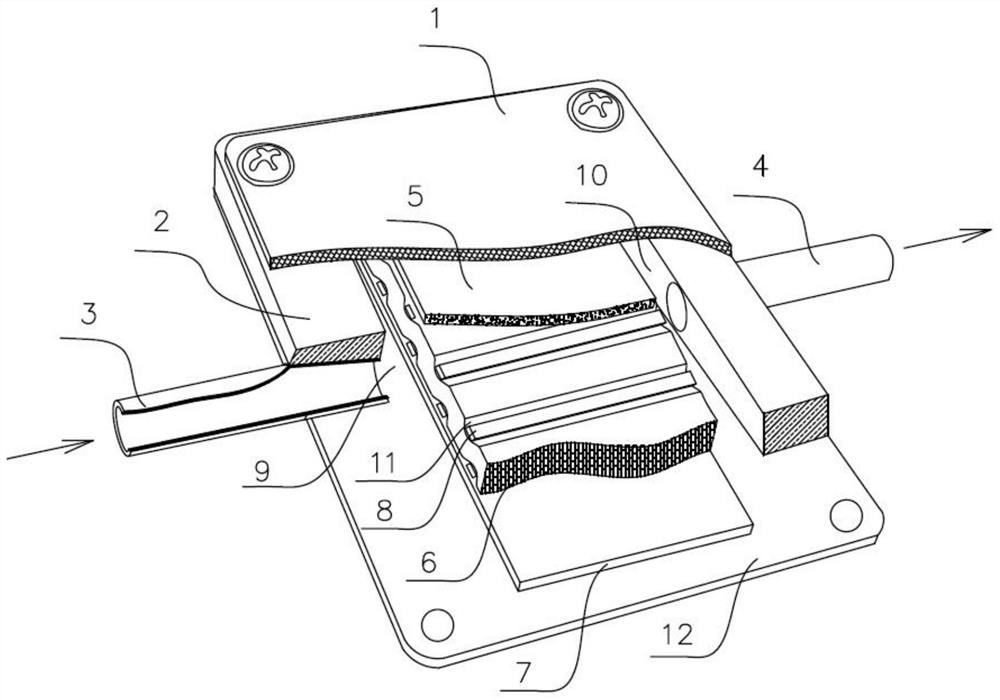

[0033] figure 2 and image 3 The internal structure and layered structure of the electrolytic cell of the present invention are shown, including an insulating frame 2, a first electrode, a second electrode, a first electrode support device, a second electrode support device, and an electrolyte membrane 6; the first electrode support device includes Several first electrode support strips 8; the second electrode support device includes several second electrode support strips 13; each firs...

no. 2 example

[0044] The difference between this embodiment and the first embodiment is that: the materials of the first electrode metal sheet 1 and the second electrode metal sheet 12 are stainless steel; the materials of the electrolyte membrane 6, the first electrode support bar 8 and the second electrode support bar 13 The same, both are perfluorinated cation exchange membrane material Fumasep-F10120. Compared with the first embodiment, the material cost of some parts used in this embodiment is lower, and the electrolysis efficiency that can be achieved is similar.

no. 3 example

[0046] The difference between this embodiment and the first embodiment is that the electrolyte membrane 6 is made of perfluorinated cation exchange membrane material Fumasep-F10120, the first electrode support bar 8 and the second electrode support bar 13 are made of perfluorosulfonic acid material Nafion-N117. The solution in this embodiment is a compromise between the first embodiment and the second embodiment. This embodiment can also achieve similar electrolysis efficiency, indicating that the materials of the first electrode support bar 8 and the second electrode support bar 13 are not the same as the electrolyte membrane 6 but belong to the same type of material, and can also achieve similar electrolytic efficiency as the first and second electrode support bars. Beneficial effects of the second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com