Method and equipment for reclaiming organic waste without pollution

A technology of organic waste and treatment device, which is applied in the removal of solid waste, educts, special forms of dry distillation, etc., can solve the problems of poor quality, long time and high temperature in the production of coke, to improve the reaction effect and reduce time, the effect of increasing the throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

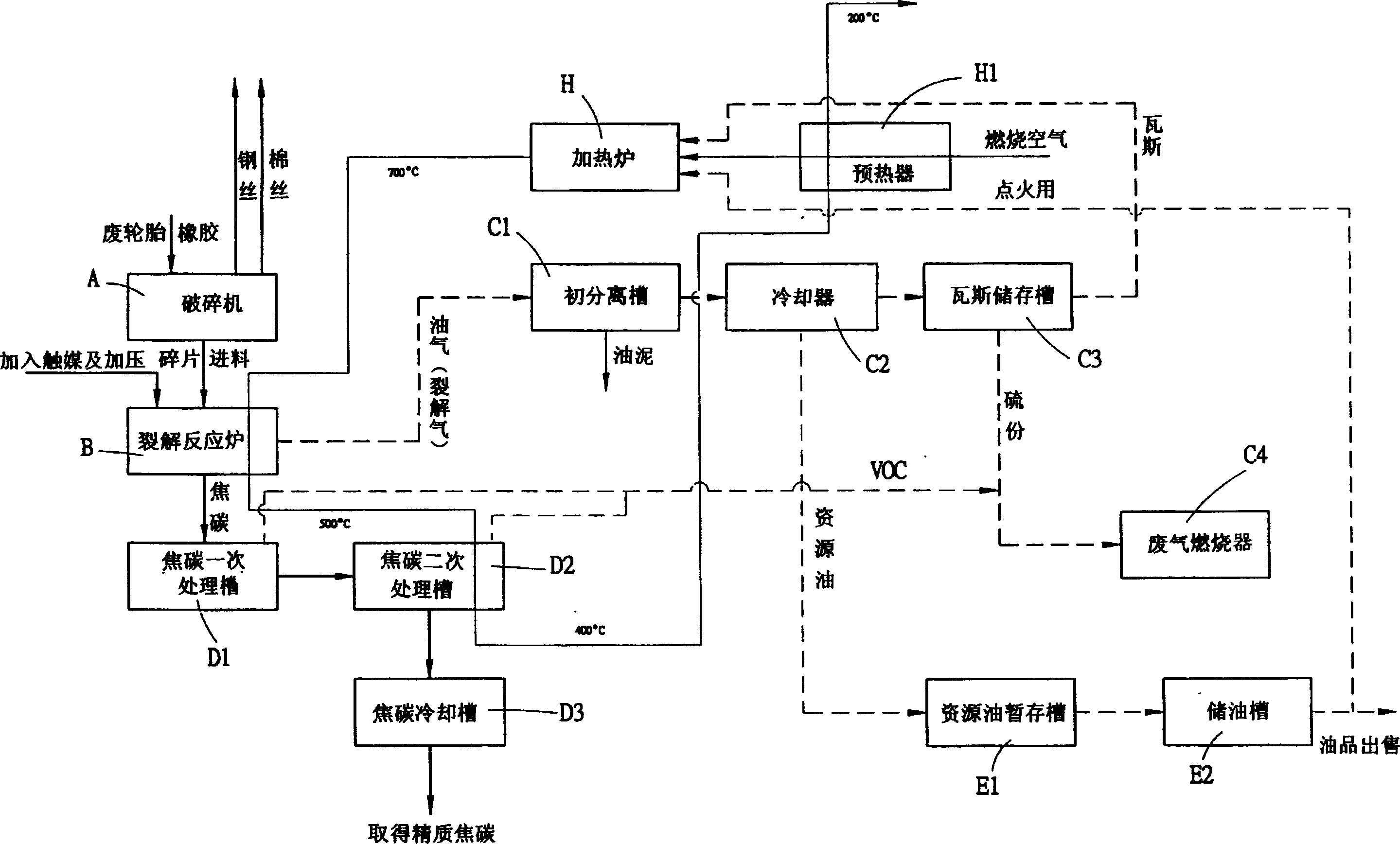

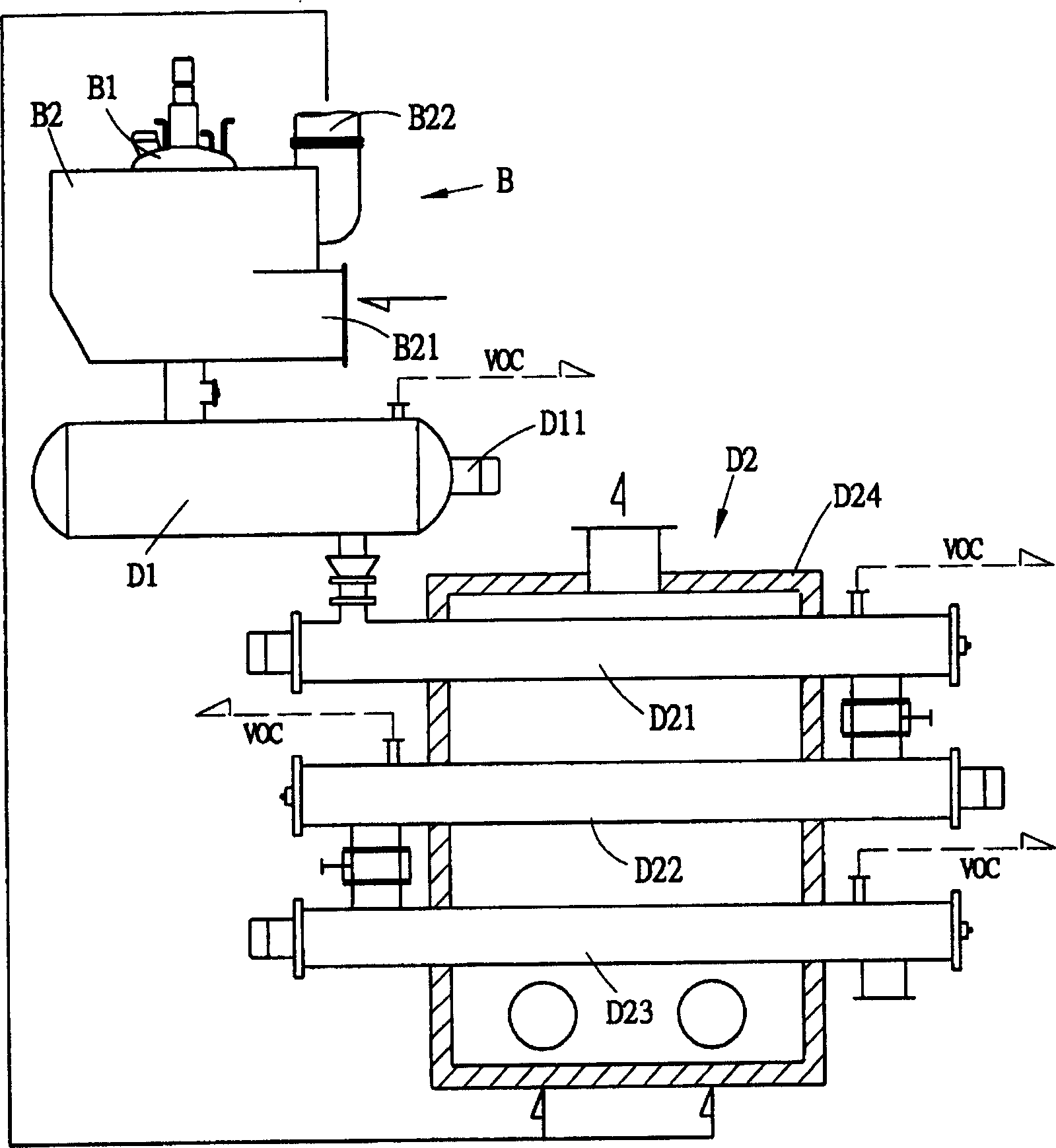

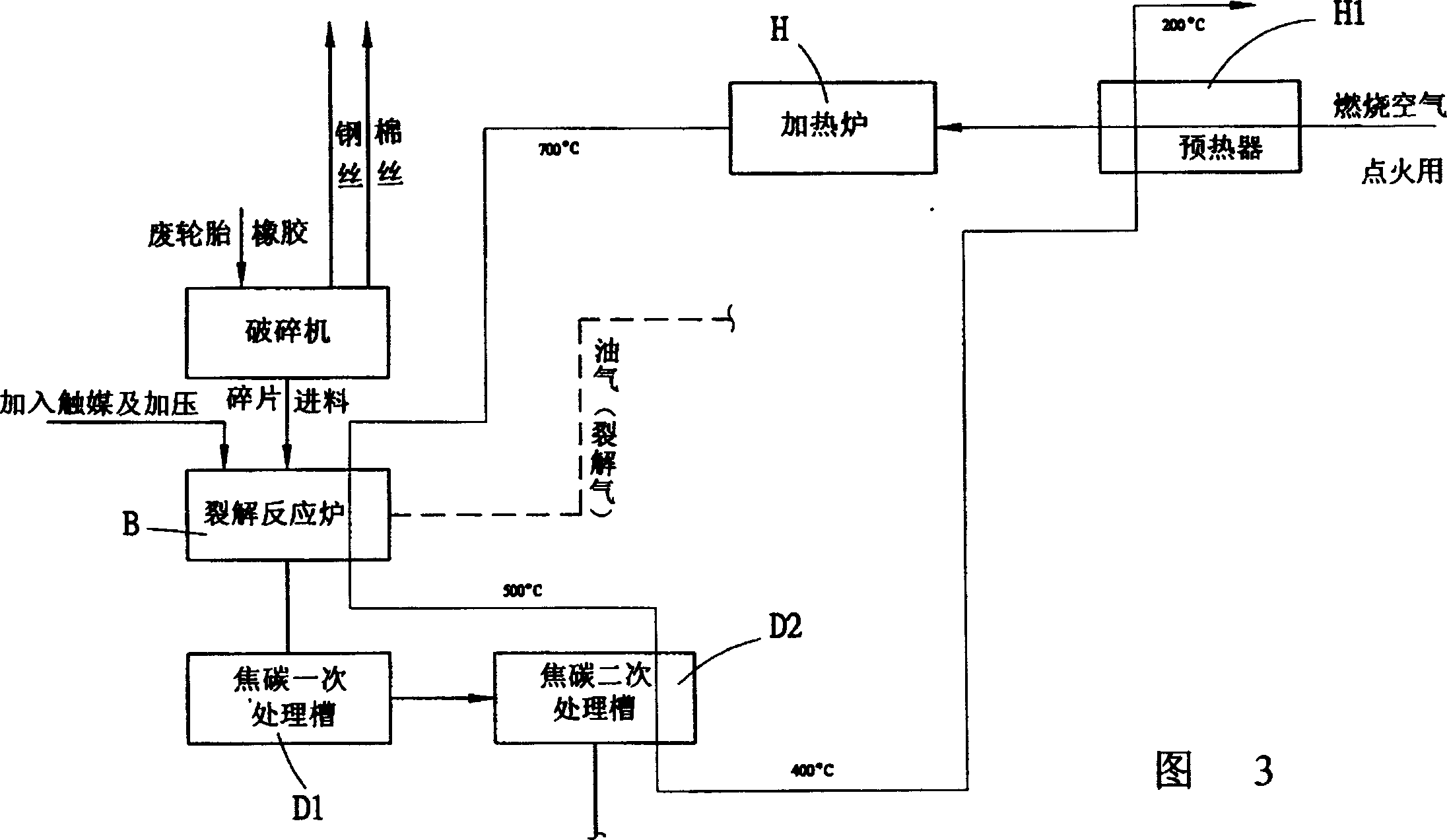

[0032] The non-pollution treatment method and device of the organic waste recycling of the present invention, the equipment and devices required in the cracking treatment process are as follows: figure 1 As shown, it is mainly based on the reaction furnace B, and is equipped with a heating furnace H to meet the needs of the cracking reaction, a primary separation tank C1 for processing the oil and gas generated by cracking, a condenser C2, and a gas storage tank C3; it is used for cooling the oil and gas Resource oil primary treatment tank E1 and oil storage tank E2 for generating resource oil; coke primary treatment tank D1, coke secondary treatment tank D2, and coke cooling tank D3 for processing cracked coke; and waste pyrolysis Crusher A for pre-operation; in the overall device, and connected to the above-mentioned units by various transportation pipelines to automatically complete the transportation of cracked gas, resource oil and coke.

[0033] The feature of the presen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com