Metallographic corrosive agent and corrosion method

A metallographic corrosion and etchant technology, which is applied to instruments, analytical materials, measuring devices, etc., can solve the problem of inability to complete the metallographic corrosion of the martensitic steel matrix and the coating at the same time, and achieve the coating structure and precipitation phase. The effect of clear imaging, clear observation and analysis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

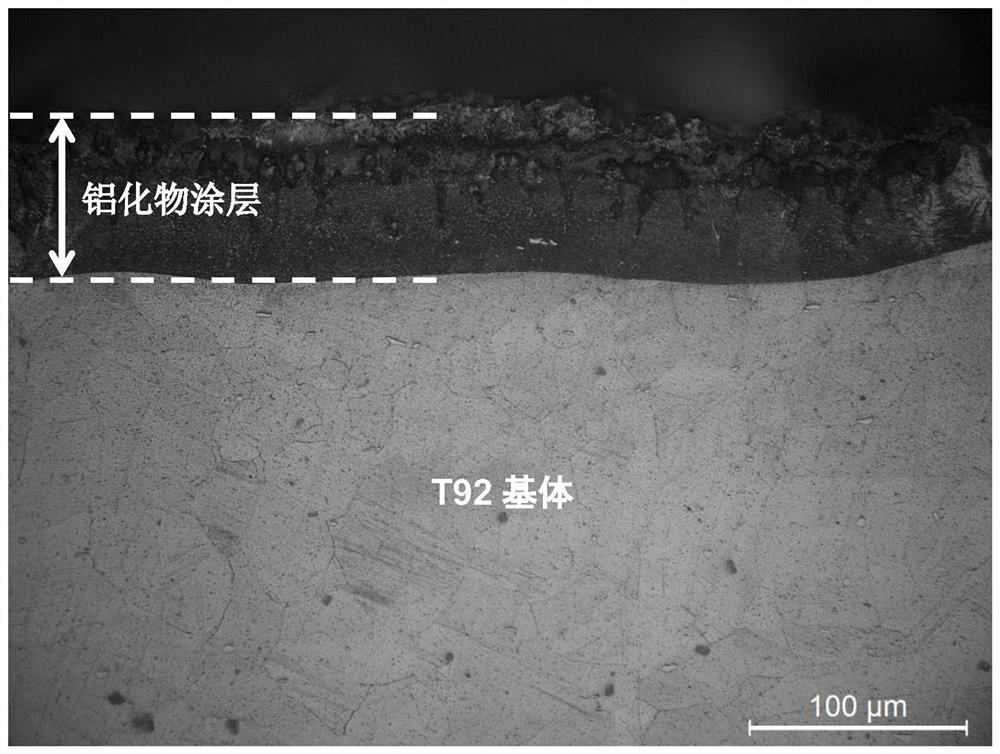

[0042] 1) Preparation of corrosion samples

[0043] The original martensitic steel aluminide coating sample was hot-mounted along the coating cross-section direction and marked on the sample with an electric engraving pen; , 1200# and 2000# water-grinding metallographic sandpaper to grind step by step; finally, use polishing cloth or flannelette on the polishing machine to polish the sample until the surface reaches the mirror-level brightness without visible coarse scratches to the naked eye; among them, the mounting powder is Conductive mounting powder, polishing paste is 1.5μm diamond spray polishing agent, and the grinding and polishing directions are perpendicular to the coating direction.

[0044] 2) Preparation of metallographic etchant

[0045] First measure the pure water of 39mL concentrated nitric acid (mass fraction 68.0%), 44mL, 9mL phosphoric acid (mass fraction 85%) and 8mL glycerol respectively according to volume percentage, take by weighing 4g iron trichlori...

Embodiment 2

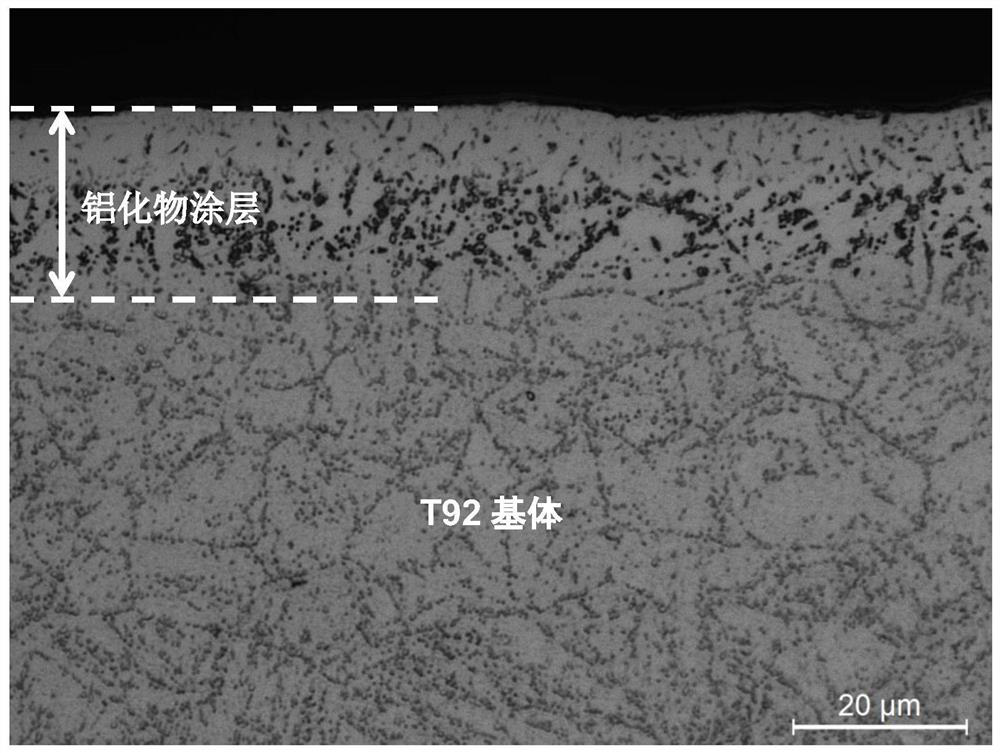

[0049] 1) Preparation of corrosion samples

[0050] Hot mount the martensitic steel aluminide coating sample in service state along the coating cross-section direction and mark on the sample with an electric engraving pen; then use 280#, 800# #, 1200#, 2000# Water-grinding metallographic sandpaper is ground step by step; finally, the sample is polished on a polishing machine with a polishing cloth or flannelette until the surface reaches a mirror-level brightness without visible coarse scratches to the naked eye; among them, the mounting powder It is conductive mounting powder, the polishing paste is 1.5μm diamond spray polishing agent, and the grinding and polishing directions are perpendicular to the coating direction.

[0051] 2) Preparation of metallographic etchant

[0052] First, measure 40mL of concentrated nitric acid, 40mL of pure water, 8mL of phosphoric acid and 12mL of glycerin according to the volume percentage, weigh 2g of ferric chloride and 10g of oxalic acid;...

Embodiment 3

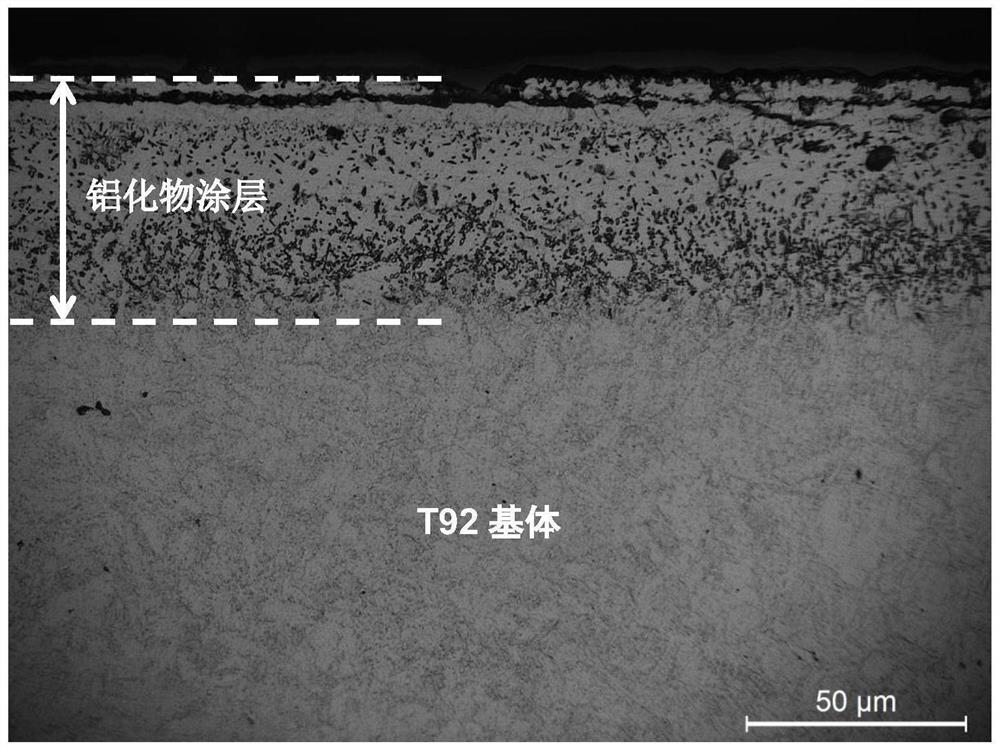

[0056] 1) Preparation of corrosion samples

[0057] The original martensitic steel aluminide coating sample was hot-mounted along the coating cross-section direction and marked on the sample with an electric engraving pen; , 1200# and 2000# water-grinding metallographic sandpaper to grind step by step; finally, use polishing cloth or flannelette on the polishing machine to polish the sample until the surface reaches the mirror-level brightness without visible coarse scratches to the naked eye; among them, the mounting powder is Conductive mounting powder, polishing paste is 1.5μm diamond spray polishing agent, and the grinding and polishing directions are perpendicular to the coating direction.

[0058] 2) Preparation of metallographic etchant

[0059] First measure respectively the pure water of 35mL concentrated nitric acid (mass fraction 68.0%), 48mL, 7mL phosphoric acid (mass fraction 85%) and 10mL glycerol according to volume percentage, take by weighing 3g iron trichlor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com