Micro-liquid node surface extractant and application thereof in surface extraction and mass spectrometry of photoinitiator sample of cigarette material

A technology of photoinitiator and extraction agent, applied in the field of mass spectrometry detection pretreatment, to reduce false negatives, improve universality and detection rate, and avoid false negatives

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

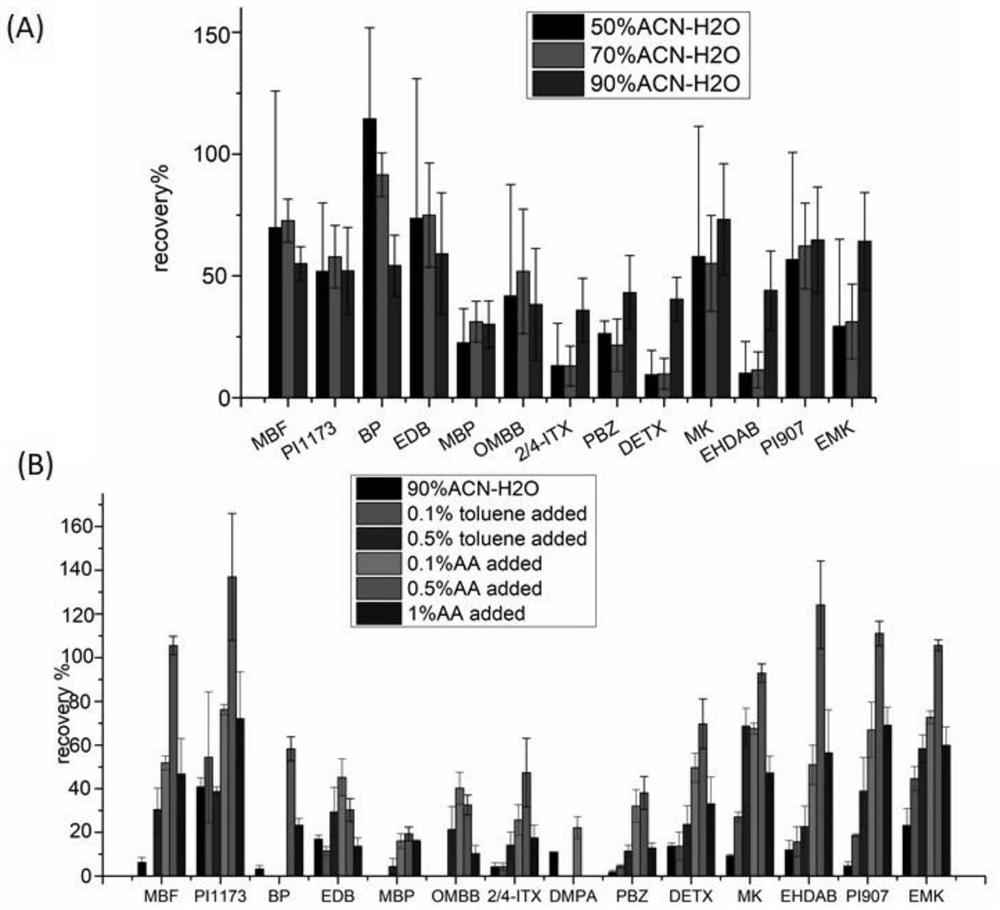

[0076] The optimum extraction solvent composition was determined by condition screening experiments. The specific steps are as follows:

[0077] (1) Extraction solvent preparation: prepare 50% acetonitrile water, 70% acetonitrile water and 90% acetonitrile water respectively. Additive selection 0.1%, 0.5% toluene, 0.1%, 0.5%, 1% acetic acid, 0.1%, 0.5%, 1% benzoic acid

[0078] (2) Production of simulated paper: add a certain concentration of photoinitiator to the ink without photoinitiator, and use a wire bar coater to coat the paper, based on the area coated, the amount of ink used, and the amount added to the standard sample The content of photoinitiator in the simulated paper can be calculated (mg / m 2 ).

[0079] (4) Microfluidic node scanning of simulated paper under different solvent conditions: the simulated paper was placed on a three-axis platform and fixed in a single-point extraction mode. The syringe pump pumps the extract into the probe at a rate of 5 μL / min. ...

Embodiment 2

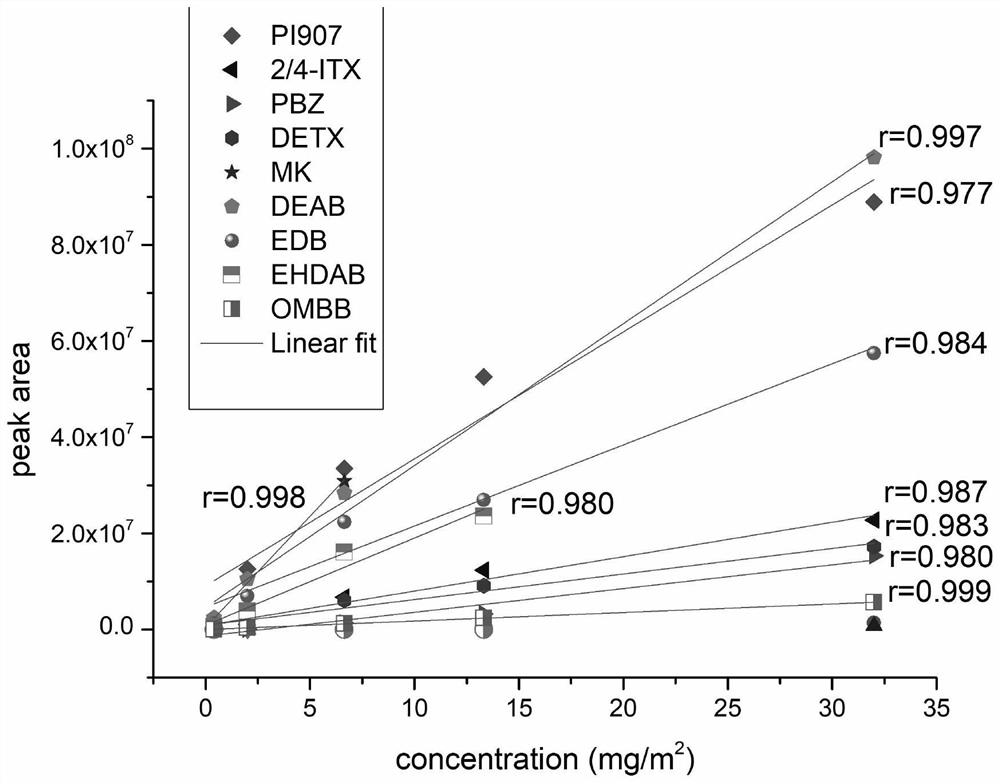

[0083] Detection of Photoinitiators in Quantitative Gradient Spiked Mimic Paper Using Microliquid Junction Mass Spectrometry. The specific steps are as follows:

[0084] (1) Production of simulated paper: add a photoinitiator with a certain concentration gradient to the ink without photoinitiator, use a wire bar coater to coat the paper, and use the coated area, the amount of ink and the amount added by the standard sample The amount can be calculated to simulate the content of photoinitiator in the paper (mg / m 2 ) are 0.4, 2, 6.64, 13.3 respectively.

[0085] (2) Scanning of simulated paper microfluidic nodes: place the simulated paper on a three-axis platform and fix it. The microfluidic junction probe scans the selected rectangular area in zigzag at a speed of 500 μm / s. At the same time, the syringe pump pumped the extraction solution (0.5% acetic acid-90% acetonitrile-water) onto the probe at a speed of 10 μL / min. The extract is drawn into the quantitative loop by the ...

Embodiment 3

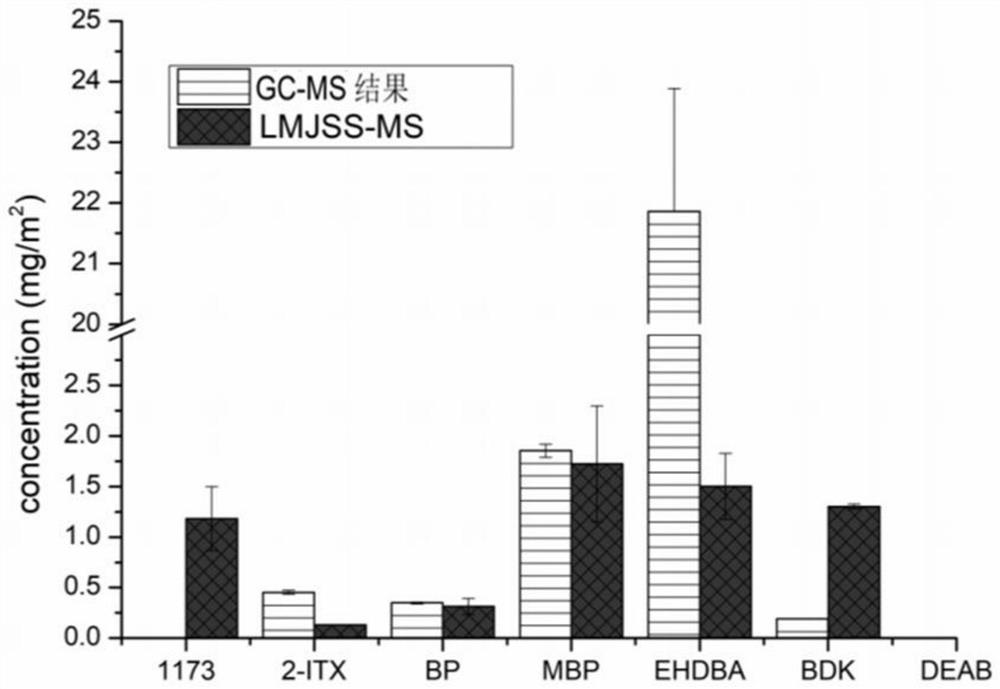

[0094] Real samples were detected by microliquid junction mass spectrometry. The specific steps are as follows:

[0095] (1) Actual sample: The actual sample for this test is a cigarette case of a certain brand.

[0096] (2) Scanning of simulated paper microfluidic nodes: place the simulated paper on a three-axis platform and fix it. The microfluidic junction probe scans the selected rectangular area in zigzag at a speed of 500 μm / s. At the same time, the syringe pump pumped the extract solution (0.5% acetic acid-90% acetonitrile water) to the probe at a speed of 10 μL / min. The extract is drawn into the quantitative loop by the vacuum pump.

[0097] (3) On-line mass spectrometry detection of the photoinitiator: After the probe scans for 1 min, the six-way valve switches the valve position so that the liquid phase pump pushes the analyte in the quantitative loop into the mass spectrometer for detection. At the same time the probe stops scanning. The detection condition of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com