Composite pipe as well as preparation method and application thereof

A composite tube and composite sheet technology, applied in the field of medical materials, can solve problems such as the release time only covering one to three months, the metabolism of degradation products, and the increase in the amount of materials, so as to achieve lightweight, reduce metabolic burden, prevent mutual influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

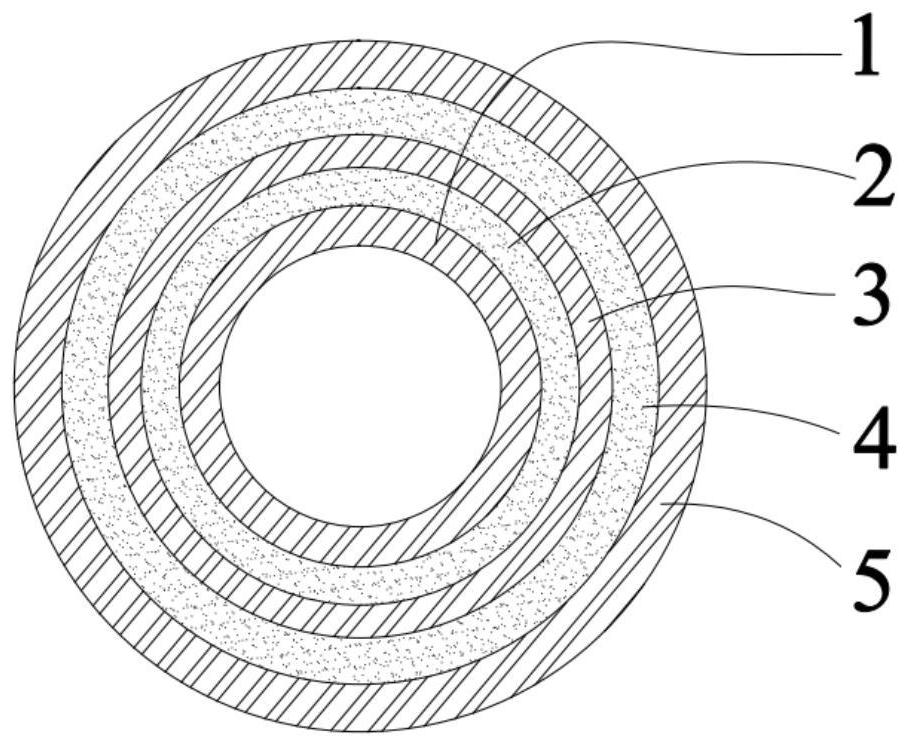

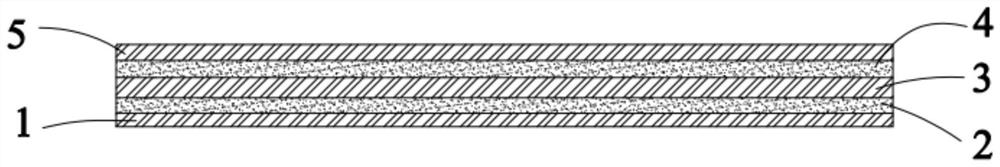

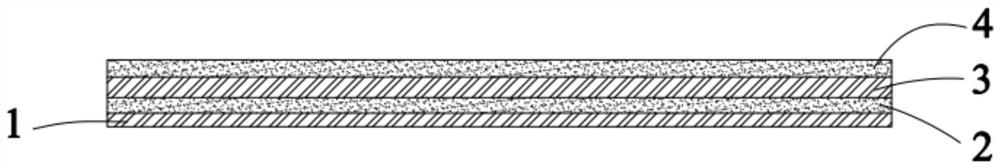

[0128] A composite pipe comprising three orientation layers and two drug-carrying layers, the orientation layers and the drug-carrying layers are arranged alternately, and the innermost and outermost layers of the pipe wall of the composite pipe are both orientation layers; each orientation layer The number of orientation directions is one, and each orientation layer is composed of a single-layer orientation film prepared from a uniaxially stretched film material (polylactic acid (PLLA) film material); The drug layer contains polycaprolactone and rapamycin, and the drug-carrying layer near the inner side of the tube wall of the composite tube contains polycaprolactone and sodium bicarbonate; the wall thickness of the composite tube is 0.06mm, and the drug-carrying amount of the composite tube is Rapamycin 1.5mg / g, sodium bicarbonate 0.5mg / g.

[0129] Its specific preparation method is as follows:

[0130] (1) 100g polycaprolactone is mixed with 0.5g sodium bicarbonate to obta...

Embodiment 2

[0135] A composite pipe comprising three orientation layers and two drug-carrying layers, the orientation layers and the drug-carrying layers are arranged alternately, and the innermost and outermost layers of the pipe wall of the composite pipe are both orientation layers; each orientation layer The number of orientation directions is one, and each orientation layer is made of a single-layer orientation film prepared by a uniaxially stretched film material (PLLA film material); Lactone and rapamycin, the drug-carrying layer near the inner side of the tube wall of the composite tube contains polycaprolactone and sodium bicarbonate; the wall thickness of the composite tube is 0.06mm, and the drug-carrying amount of the composite tube is 1.5% rapamycin mg / g, sodium bicarbonate 0.5mg / g.

[0136] The only difference between the preparation method and Example 1 is that in step (2), the superimposition of the orientation layers adopts alignment and superposition, so that the number ...

Embodiment 3

[0138] A composite pipe comprising three orientation layers and two drug-carrying layers, the orientation layers and the drug-carrying layers are arranged alternately, and the innermost and outermost layers of the pipe wall of the composite pipe are both orientation layers; each orientation layer The number of orientation directions is one, and each orientation layer is made of a single-layer orientation film prepared by a uniaxially stretched film material (PLLA film material); Lactone and rapamycin, the drug-carrying layer near the inner side of the tube wall of the composite tube contains polycaprolactone and sodium bicarbonate; the wall thickness of the composite tube is 0.05mm, and the drug-carrying amount of the composite tube is 1.5% rapamycin mg / g, sodium bicarbonate 0.5mg / g.

[0139] The only difference between the preparation method and Example 1 is that in step (4), it also includes applying a pulling force of 3N / mm to the two ends of the nascent composite pipe 2 T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com