Treatment method of high-iron material containing nickel-cobalt-manganese hydroxide

A hydroxide and treatment method technology, applied in nickel compounds, chemical instruments and methods, inorganic chemistry, etc., can solve the problems of difficult treatment technology, cumbersome process, high production site requirements, etc., and achieve low treatment technology difficulty and high treatment equipment Simple, site-friendly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

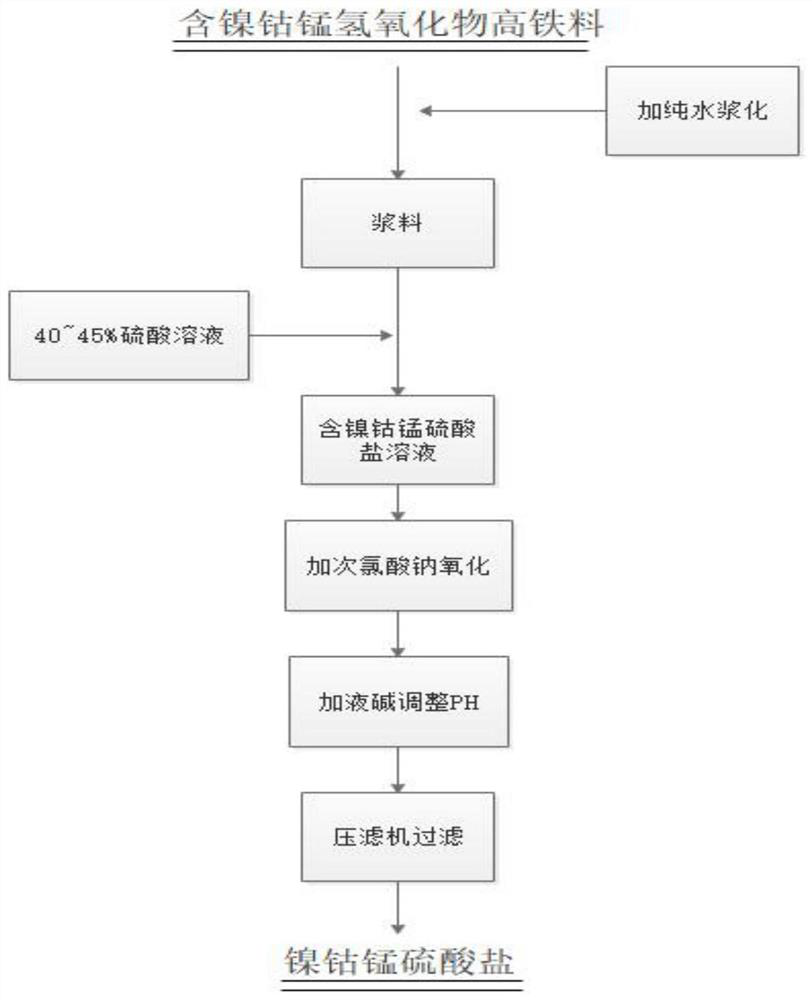

Method used

Image

Examples

Embodiment 1

[0027] Treat the nickel-cobalt-manganese hydroxide high-iron material as follows:

[0028] S1, confirmation 5m 3 The integrity of the dissolution kettle, the solution overflow conduit and piping accessories such as sulfuric acid and pure water are unobstructed.

[0029] S2, add about 1m to the kettle 3 The hot pure water (measured temperature 79 ℃), start stirring, slowly add 250kg nickel-cobalt-manganese hydroxide high-iron material from the still mouth and carry out slurrying.

[0030] S3. After slurrying, turn on the concentrated sulfuric acid injection pump, slowly inject concentrated sulfuric acid with a mass concentration of 45% at a rate of 200L / h, and observe the boiling state of the dissolution kettle to prevent the slurry from escaping until the slurry is completely dissolved.

[0031] S4. After dissolving, overflow the solution to the oxidation tank, keep the temperature at 70-90°C, add an appropriate amount of sodium hypochlorite, and continuously pipette an appr...

Embodiment 2

[0036] Treat the nickel-cobalt-manganese hydroxide high-iron material as follows:

[0037] S1, confirm 10m 3 The integrity of the dissolution kettle, the solution overflow conduit and piping accessories such as sulfuric acid and pure water are unobstructed.

[0038] S2, add about 3m to the kettle 3 The hot pure water (measured temperature 78 ℃), start stirring, slowly add 750kg nickel-cobalt-manganese hydroxide high-iron material from the still mouth and carry out slurrying.

[0039] S3. After slurrying, turn on the concentrated sulfuric acid injection pump, slowly inject concentrated sulfuric acid with a mass concentration of 45% at a rate of 200L / h, and observe the boiling state of the dissolution kettle to prevent the slurry from escaping until the slurry is completely dissolved.

[0040] S4. After dissolving, overflow the solution to the oxidation tank, keep the temperature at 70-90°C, add an appropriate amount of sodium hypochlorite, and continuously pipette an appropri...

Embodiment 3

[0045] Treat the nickel-cobalt-manganese hydroxide high-iron material as follows:

[0046] S1, confirm 10m 3 The integrity of the dissolution kettle, the solution overflow conduit and piping accessories such as sulfuric acid and pure water are unobstructed.

[0047] S2, add about 5m to the kettle 3The hot pure water (measured temperature 78 ℃), start stirring, slowly add 1250kg nickel-cobalt-manganese hydroxide high-iron material from the still mouth and carry out slurrying.

[0048] S3. After slurrying, turn on the concentrated sulfuric acid injection pump, slowly inject concentrated sulfuric acid with a mass concentration of 45% at a rate of 200L / h, and observe the boiling state of the dissolution kettle to prevent the slurry from escaping until the slurry is completely dissolved.

[0049] S4. After dissolving, overflow the solution to the oxidation tank, keep the temperature at 70-90°C, add an appropriate amount of sodium hypochlorite, and continuously pipette an appropri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com