Multifunctional all-in-one machine for harmless treatment of livestock and poultry excrement

A technology for harmless treatment of livestock and poultry manure, applied in the fields of bio-organic part treatment, organic fertilizer, climate change adaptation, etc., can solve problems such as environmental pollution, demand growth, fresh material accumulation, etc., to reduce environmental sanitation, reduce stacked effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

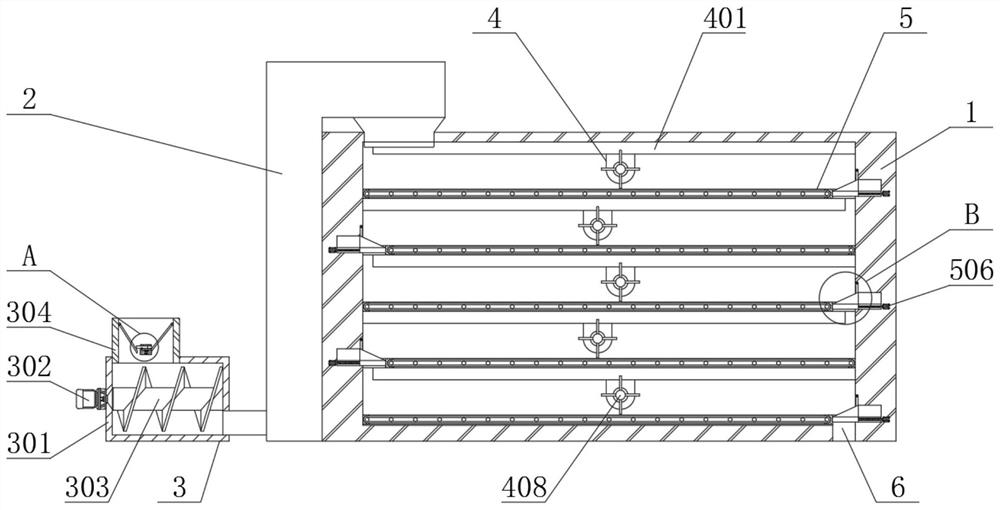

[0026] see Figure 1-6 , the present invention provides a technical solution:

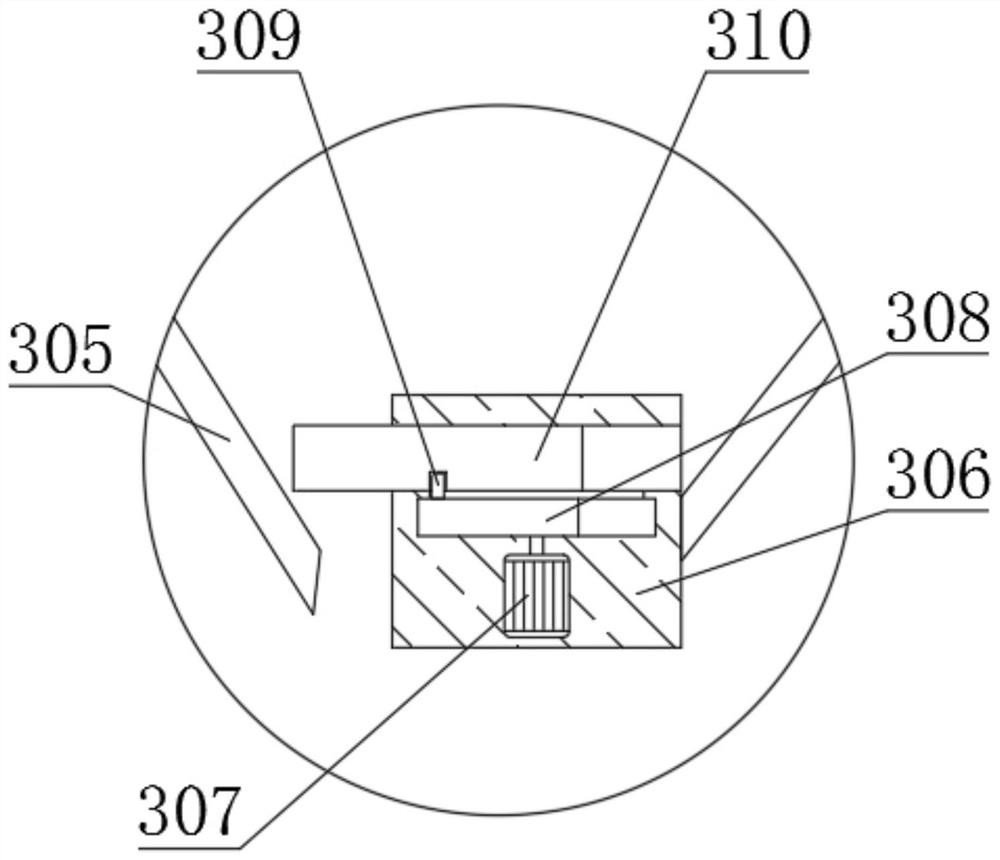

[0027] A multifunctional all-in-one machine for the harmless treatment of livestock and poultry feces, comprising a heat preservation treatment box main body 1, the left end of the heat preservation treatment box main body 1 is fixedly connected with a feed hoist 2, and the top of the feed hoist 2 is connected to the heat preservation treatment box main body 1 is connected to the top, and the left end of the feeding hoist 2 is connected to a stirring auxiliary material mechanism 3, which includes an auxiliary material bin 301, a stirring motor 302, a stirring shaft 303, a feeding bin 304, a material guide plate 305, a fixing bar 306, Reciprocating motor 307, eccentric wheel 308, limit rod 309 and reciprocating push rod 310, the inboard of heat preservation treatment box main body 1 is provided with mobile turning mechanism 4 and automatic blanking device 5, and moving turning mechanism 4 comprises ...

Embodiment 2

[0031] see Figure 1-6 , the present invention provides a technical solution:

[0032] A multi-functional all-in-one machine for the harmless treatment of livestock and poultry excrement. The parts in Embodiment 2 that are the same as those in Embodiment 1 will not be repeated in the present invention, and the difference lies in the working process.

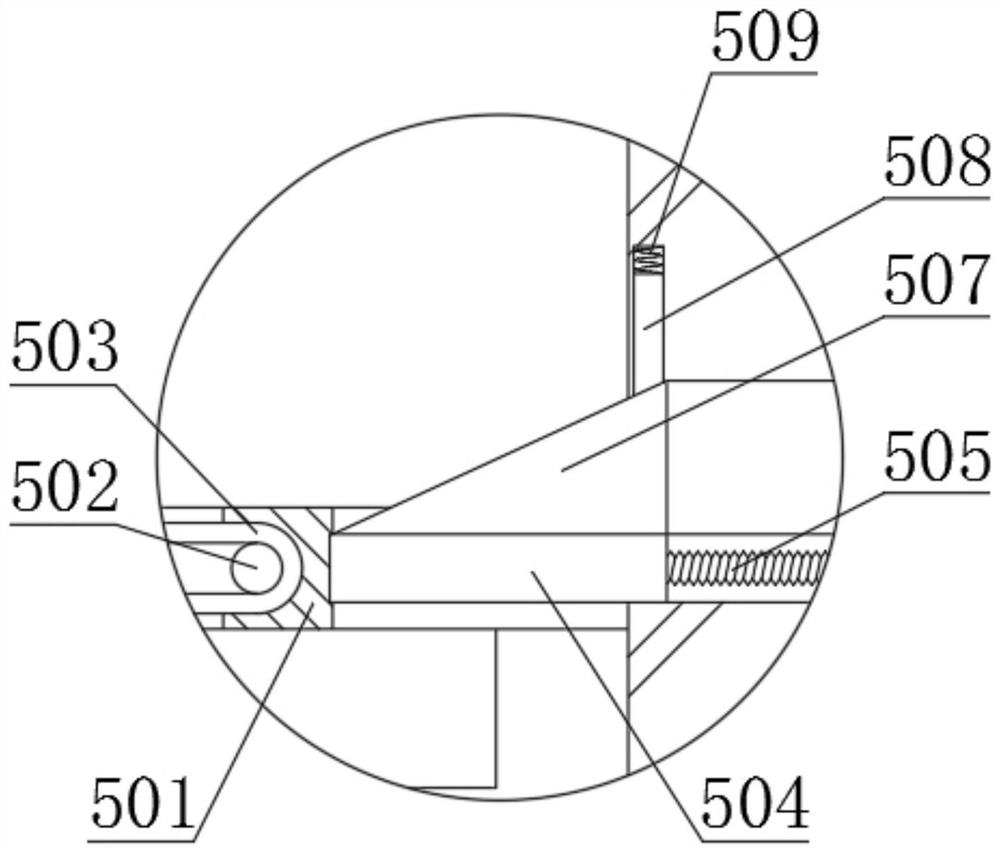

[0033] Working process: In the present invention, when the feces material inside the main body 1 of the thermal insulation treatment box is less and no fresh material enters, the electric spindle 502 can drive the mesh bag 503 to move, and the mesh bag 503 will drive the feces material above it to the same place as At the opposite end of the sealing plate 504, the materials of the same layer are concentrated at one end of the mesh bag 503, and the material will not be dropped from the position of the sealing plate 504, and then the operation of the automatic blanking mechanism 5 is stopped, and the driving motor 406 is started to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com