Nano titanium-doped modified graphene high-performance anticorrosive coating and preparation method thereof

An anti-corrosion coating, graphene technology, applied in anti-corrosion coatings, epoxy resin coatings, coatings, etc., can solve the problems of difficult to achieve layer-by-layer protection effect, compactness and integrity effects, and difficult to uniformly disperse anti-corrosion coatings. , to achieve the effects of excellent chemical stability, strong film formation, and improved anti-oxidative corrosion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

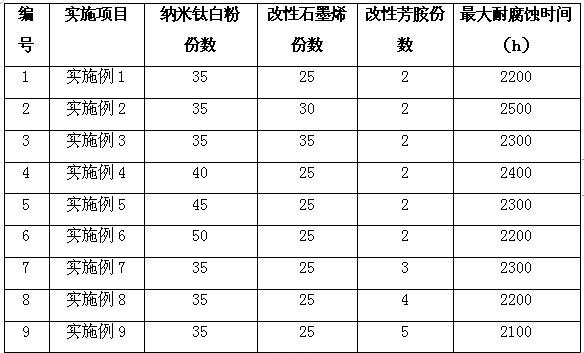

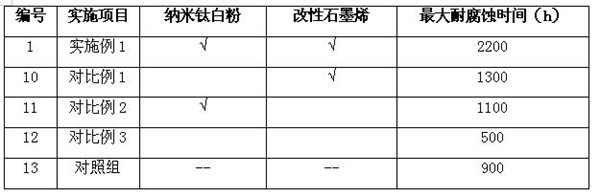

Examples

preparation example Construction

[0033] In an embodiment of the present invention, the preparation method of the modified graphene comprises the following steps:

[0034] 1) Mix the graphene raw material, co-solvent and coupling agent, and stir in an ultrasonic reactor to obtain a graphene suspension;

[0035] 2) Mix the graphene suspension with water and heat at 100-120°C for 2 hours to obtain crude modified graphene;

[0036] 3) The crude modified graphene is sequentially subjected to solid-liquid separation, washing and drying to obtain modified graphene.

[0037] The embodiment of the present invention also provides a preparation method of the nano-titanium-doped modified graphene high-performance anti-corrosion coating, comprising the following steps:

[0038] 1) Mix nano-titanium dioxide and epoxy resin, and use a high-speed disperser to pre-disperse it to obtain a dispersion;

[0039] 2) Grinding the dispersion sufficiently to obtain a grinding product;

[0040] 3) Mix the abrasive, modified graphen...

Embodiment 1

[0046] Mix 25 parts of graphene raw materials, 3 parts of sodium benzoate and 3 parts of titanate, and stir through an ultrasonic reactor to obtain a graphene suspension;

[0047] Mix the prepared graphene suspension with 40 parts of water, and heat at 120° C. for 2 hours to obtain crude modified graphene;

[0048] The obtained modified graphene crude product is subjected to solid-liquid separation, washing and drying in sequence to obtain modified graphene;

[0049] 35 parts of nano-titanium dioxide and 250 parts of epoxy resin are mixed, and a high-speed disperser is used to pre-disperse it to obtain a dispersion;

[0050] Fully grinding the obtained dispersion to obtain a ground product;

[0051] Mix the prepared grind, modified graphene and 2 parts of modified aromatic amines, and stir with a mixer for 15 minutes to obtain a semi-finished anti-corrosion coating;

[0052] A bag filter is used to filter the semi-finished anti-corrosion coating to obtain a finished anti-cor...

Embodiment 2

[0054] Mix 30 parts of graphene raw materials, 3 parts of sodium benzoate and 3 parts of titanate, and stir in an ultrasonic reactor to obtain a graphene suspension;

[0055] Mix the prepared graphene suspension with 40 parts of water, and heat at 120° C. for 2 hours to obtain crude modified graphene;

[0056] The obtained modified graphene crude product is subjected to solid-liquid separation, washing and drying in sequence to obtain modified graphene;

[0057] 35 parts of nano-titanium dioxide and 250 parts of epoxy resin are mixed, and a high-speed disperser is used to pre-disperse it to obtain a dispersion;

[0058] Fully grinding the obtained dispersion to obtain a ground product;

[0059] Mix the prepared grind, modified graphene and 2 parts of modified aromatic amines, and stir with a mixer for 15 minutes to obtain a semi-finished anti-corrosion coating;

[0060] A bag filter is used to filter the semi-finished anti-corrosion coating to obtain a finished anti-corrosio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com