Carbon tank electromagnetic valve and pipeline system for eliminating airflow pulsation and noise in vehicle

A technology for in-vehicle noise and airflow pulsation, which is applied in the charging system, the valve's device for absorbing fluid energy, and pipe components, which can solve the problems of reducing pipeline flow performance, high cost, and occupying space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

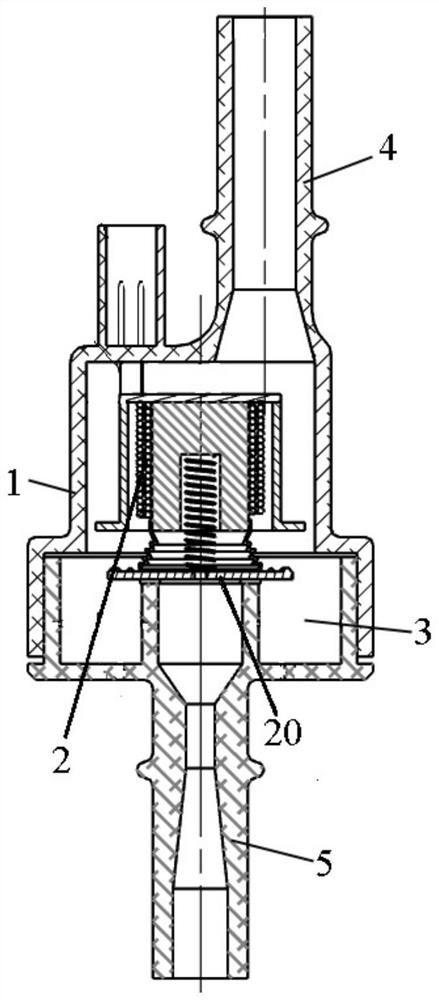

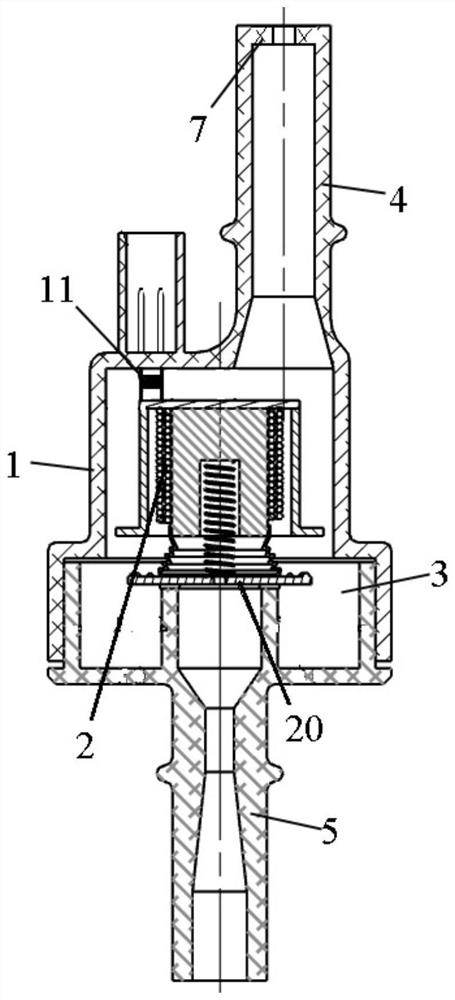

[0045] If there is a description of the direction (up, down, inside and outside) in the present invention, it is based on Figure 4 The structure shown in is a reference description, but the actual application direction of the present invention is not limited thereto. Wherein, the bushing 8 is inside, and the upstream pipeline 6 is outside; the upstream pipeline 6 is on the top, and the intake pipe 4 is on the bottom.

[0046] Combine below Figure 3 to Figure 19 , a carbon canister solenoid valve and pipeline system for eliminating airflow pulsation and interior noise of the present invention will be further described in detail.

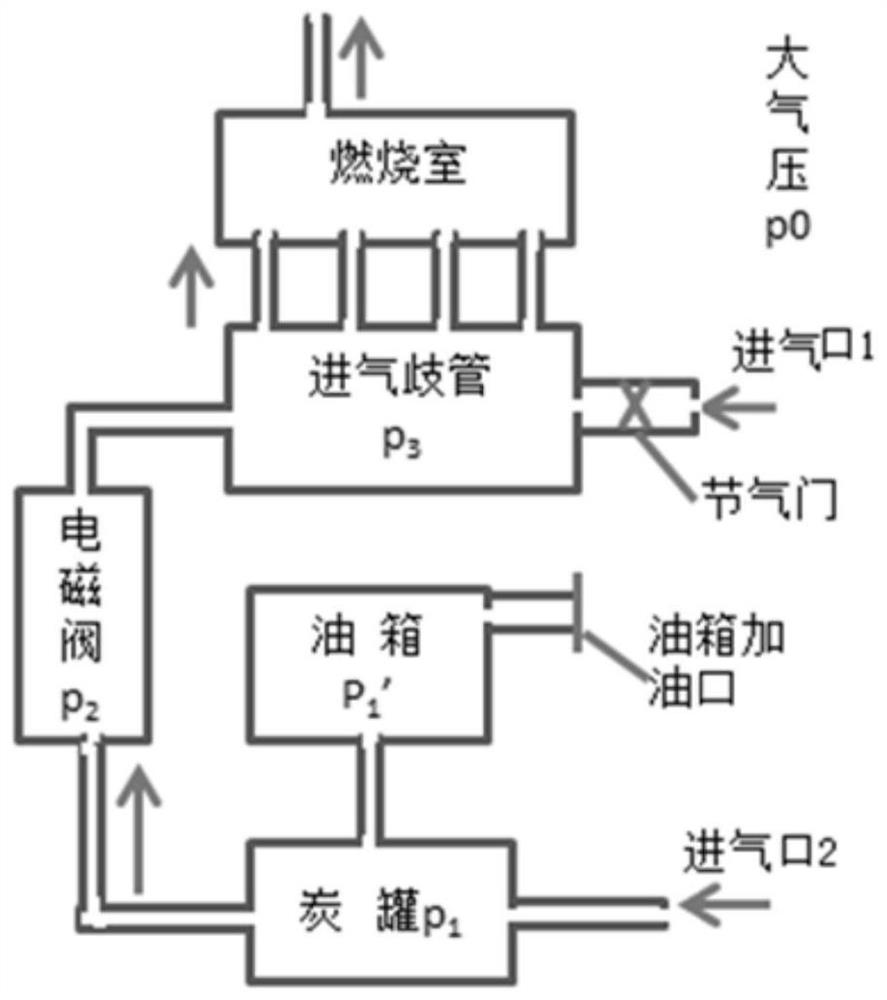

[0047] A carbon canister solenoid valve and pipeline system that eliminates airflow pulsation and noise in the car according to the present invention, please refer to Figure 3 to Figure 17 , comprising a solenoid valve, an upstream pipeline 6 and a downstream pipeline, the solenoid valve comprises a valve body 1 and an inductance coil 2 arranged ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com