Power storage device composition, power storage device electrode slurry, power storage device electrode, and power storage device

A storage device and composition technology, applied in the direction of non-aqueous electrolyte battery electrodes, battery electrodes, hybrid capacitor electrodes, etc., can solve the problems of capacity reduction, active material stripping, and failure to maintain adhesion, etc., to improve battery performance, Effect of improving softness and adhesiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0139] 2.2.4. Preparation method of slurry for storage device electrodes

[0140] The slurry for an electrical storage device electrode according to this embodiment may be a slurry for an electrical storage device electrode produced by any method as long as it contains the above-mentioned composition for an electrical storage device and an active material. Manufactured by the method described in et al.

[0141] 3. Electrode of electrical storage equipment

[0142] The electrical storage device electrode of the present embodiment includes a current collector and an active material layer formed by applying and drying the above-mentioned slurry for electrical storage device electrodes on the surface of the current collector. The electrical storage device electrode is manufactured by coating the above-mentioned slurry for electrical storage device electrodes on the surface of a current collector such as a metal foil to form a coating film, and then drying the coating film to form...

Embodiment 2~25

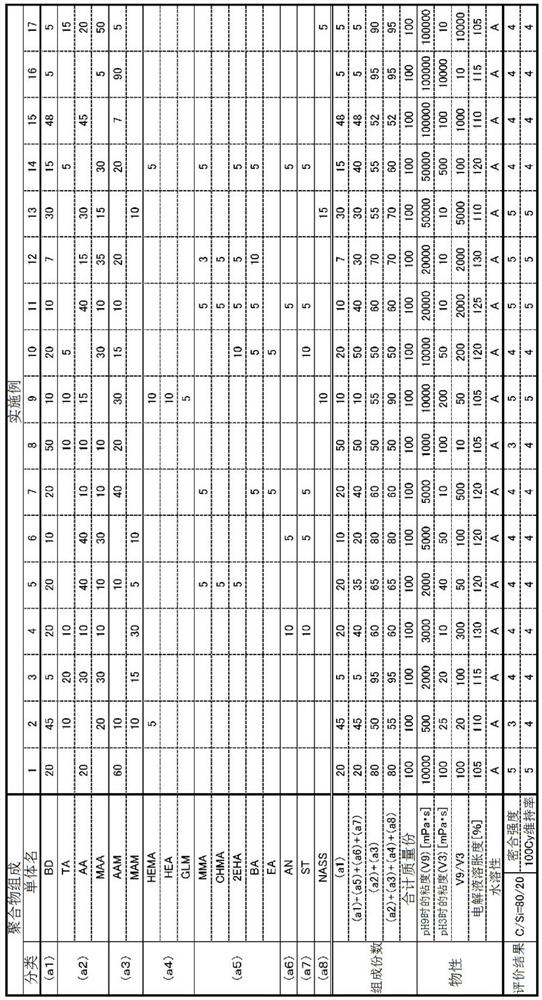

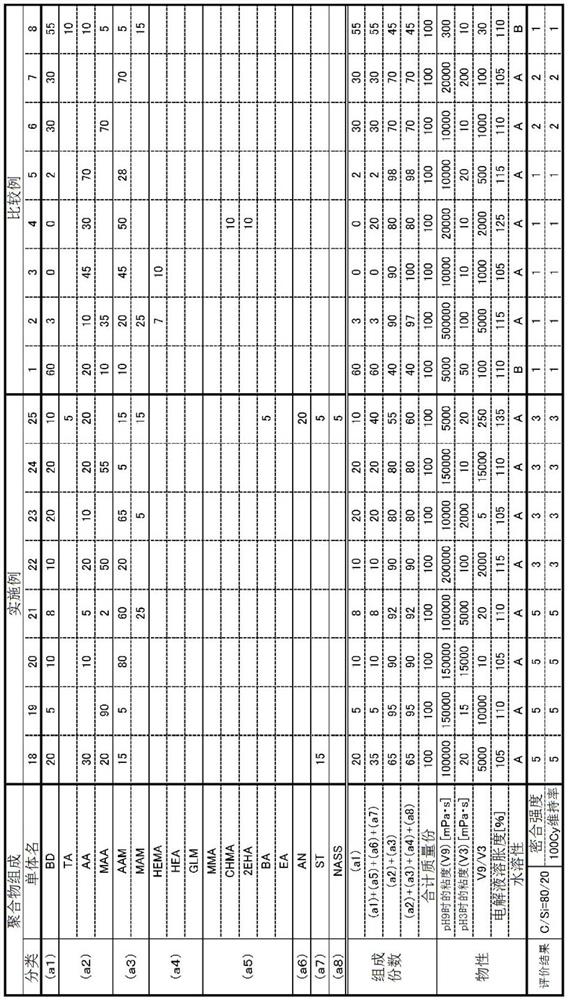

[0194] 5.2. Examples 2-25, Comparative Examples 1-8

[0195] In the above "5.1.1. Preparation and evaluation of the composition for electrical storage devices (1) Preparation of the composition for electrical storage devices", the types and amounts of each monomer are as described in Table 1 or Table 2 below. , except that, it carried out similarly, and obtained the composition for electrical storage devices containing 20 mass % of polymer components. It should be noted that in this specification, the polymer (A) obtained in Example 1 is referred to as "polymer (A1)", and the polymer (A) obtained in Example 7 is similarly referred to as "polymer (A7)", the polymer (A) obtained in Example 14 is called "polymer (A14)", etc. In addition, the polymer obtained in Comparative Example 1 is referred to as "polymer (B1)", and the polymer obtained in Comparative Example 5 is similarly referred to as "polymer (B5)", etc.

[0196] Furthermore, except for using the composition for electr...

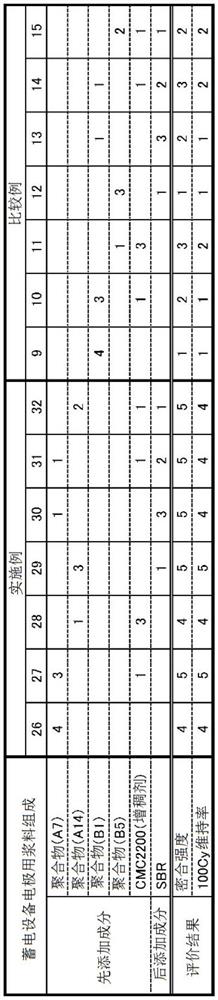

Embodiment 31

[0198] The composition for electrical storage devices of pH9.0 containing 20 mass % of polymers (A7) was obtained similarly to Example 7. Next, 1 part by mass of a thickener (trade name "CMC2200", manufactured by Daicel Co., Ltd.) was put into a twin-shaft planetary mixer (manufactured by Primex Co., Ltd., trade name "TK HIVIS MIX 2P-03") as a component to be added first. (in terms of solid content, added as an aqueous solution with a concentration of 2% by mass), 1 part by mass of polymer (A7) (in terms of solid content, as a battery at pH 9.0 containing 20% by mass of the polymer (A7) obtained above equipment composition), 76 parts by mass (in terms of solid content) of artificial graphite (manufactured by Hitachi Chemical Industry Co., Ltd., trade name "MAG") as a highly crystalline graphite as a negative electrode active material, the graphite coating obtained above 19 parts by mass of film silicon oxide powder (in terms of solid content) and 1 part by mass of carbon (De...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap