Graphene nanoparticle composite material with high conductivity and preparation method thereof

A nanoparticle and composite material technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of reducing the electrical conductivity of graphene nanoparticle composite materials and the difficulty in realizing graphene and nanoparticle electronics. Problems such as effective transfer, unstable compounding of nanoparticles and graphene, etc., to achieve good economic benefits and application prospects, good application prospects, and the effect of improving adhesion and contact performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

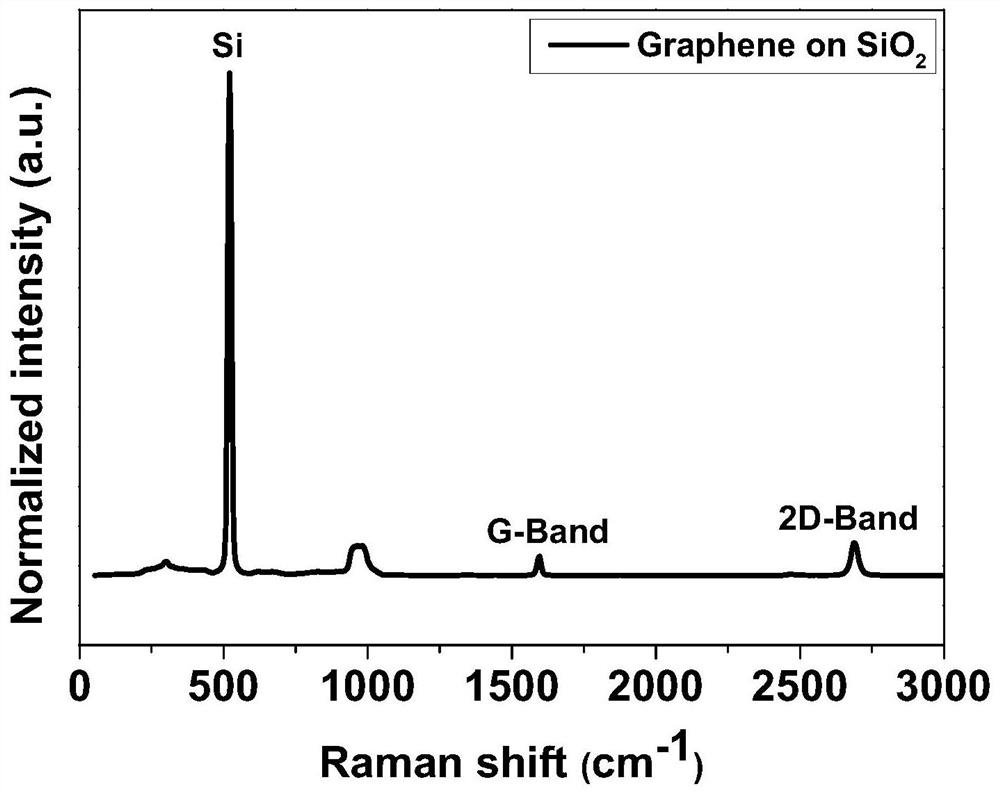

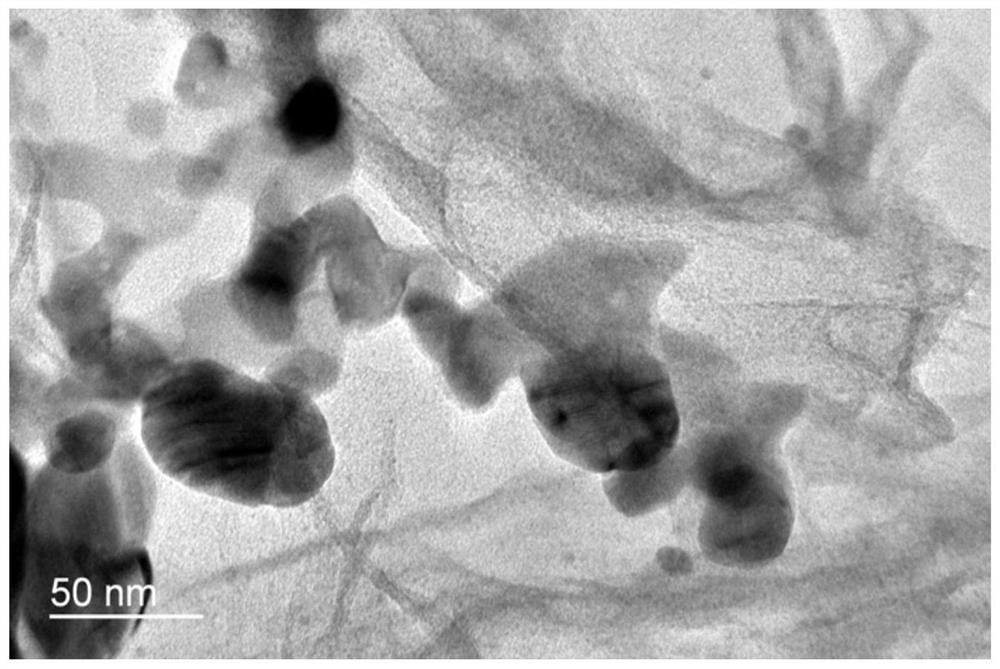

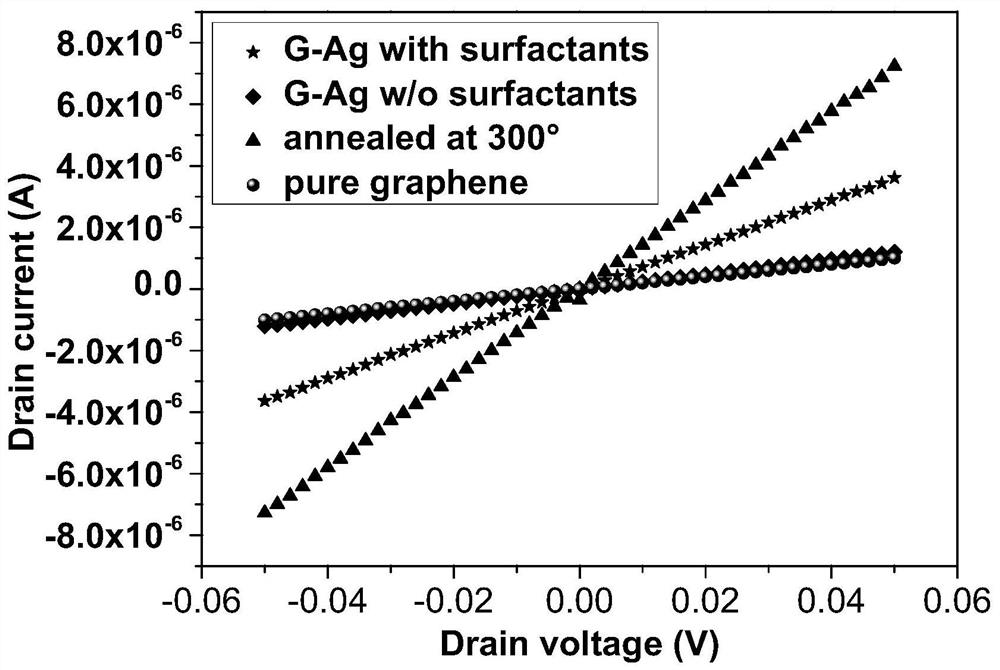

[0051] Example 1, such as Figure 1-3 Shown, a kind of preparation method of the graphene nano particle composite material with high electrical conductivity in the present embodiment, comprises the following steps:

[0052] S1, the AgNO 3 Add PVP (polyvinylpyrrolidone) to deionized water, and supplemented by stirring, to obtain a mixed solution A;

[0053] S2, the NaBH 4 The solution is added to the mixed solution A in the step S1, and supplemented with stirring until the color of the solution changes from transparent to dark yellow, and the stirring is stopped to obtain the mixed solution B;

[0054] S3, performing the first high-speed centrifugation treatment on the mixed solution B in the step S2, drying the precipitate of the mixed solution B after the first high-speed centrifugation treatment, to obtain the first metal nanoparticles;

[0055] S4. Mix the first metal nanoparticles and PEG (polyethylene glycol) in the step S3 and add them into the DMF (dimethylformamide)...

Embodiment 2

[0078] Embodiment 2, a kind of preparation method of the graphene nanoparticle composite material with high electrical conductivity in the present embodiment, comprises the following steps:

[0079] S1, the AgNO 3 Add PVP (polyvinylpyrrolidone) to deionized water, and supplemented by stirring, to obtain a mixed solution A;

[0080] S2, the NaBH 4 The solution is added to the mixed solution A in the step S1, and supplemented with stirring until the color of the solution changes from transparent to dark yellow, and the stirring is stopped to obtain the mixed solution B;

[0081] S3, performing the first high-speed centrifugation treatment on the mixed solution B in the step S2, drying the precipitate of the mixed solution B after the first high-speed centrifugation treatment, to obtain the first metal nanoparticles;

[0082] S4, mixing the first metal nanoparticles in the step S3 with PEG (polyethylene glycol) and then adding it into a DMF (dimethylformamide) solution, supplem...

Embodiment 3

[0102] Embodiment 3, a kind of preparation method of the graphene nano particle composite material with high electrical conductivity in the present embodiment, comprises the following steps:

[0103] S1, the AgNO 3 Add PVP (polyvinylpyrrolidone) to deionized water, and supplemented by stirring, to obtain a mixed solution A;

[0104] S2, the NaBH 4 The solution is added to the mixed solution A in the step S1, and supplemented with stirring until the color of the solution changes from transparent to dark yellow, and the stirring is stopped to obtain the mixed solution B;

[0105] S3, performing the first high-speed centrifugation treatment on the mixed solution B in the step S2, drying the precipitate of the mixed solution B after the first high-speed centrifugation treatment, to obtain the first metal nanoparticles;

[0106] S4. Mix the first metal nanoparticles and PEG (polyethylene glycol) in the step S3 and add them into the DMF (dimethylformamide) solution, supplemented b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com