Hydrocarbon fuel for solid fuel ramjet engine and preparation method thereof

A ramjet, hydrocarbon fuel technology, applied in the field of hydrocarbon fuel and its preparation, can solve the problems of high energy consumption, high cost, long production cycle, etc., to improve cleanliness, save cost and time, and reduce characteristics of tail smoke Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

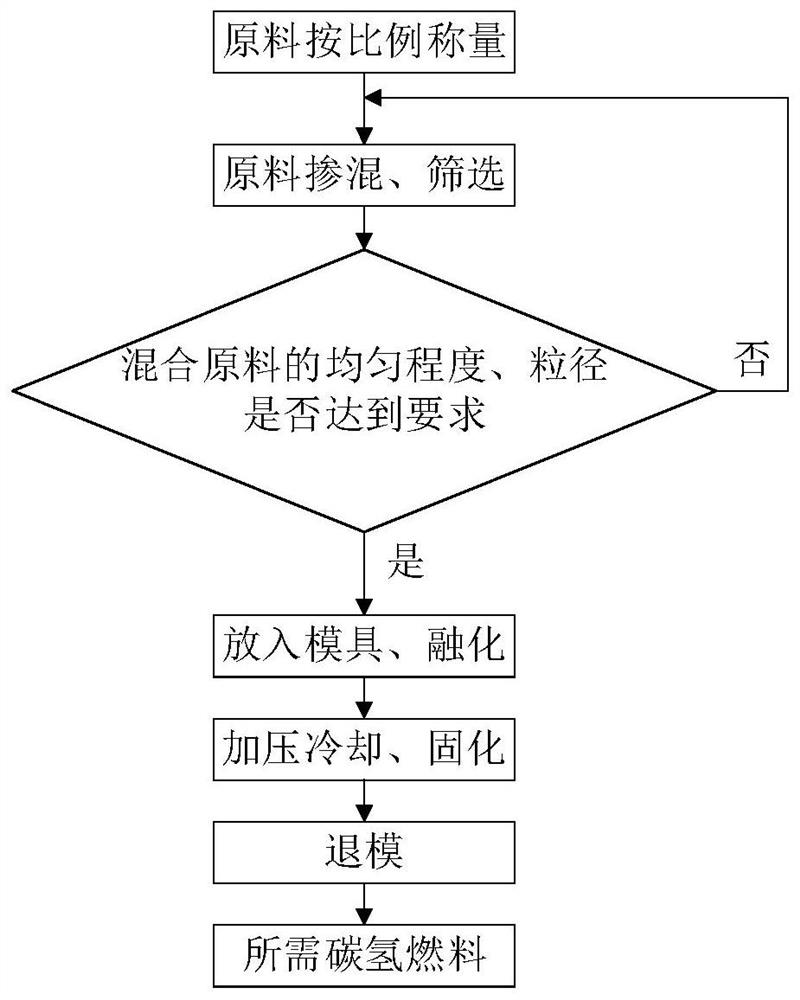

Method used

Image

Examples

Embodiment 1

[0032] Hydrocarbon fuels for solid fuel ramjet engines, including, by mass percentage:

[0033] Hydrocarbon fuel pellets: 68% high-density polyethylene, 30% fully refined paraffin wax No. 58.

[0034] Carbon functional additives: carbon black 2%.

[0035] The preparation method is:

[0036] (1) Weighing: Accurately weigh the formulations of each component in a dry environment, and put them into different containers for later use;

[0037] (2) Blending: Add the above components into a blender for mixing, control the mixing temperature to 40°C, and mix for 90 minutes to obtain a slurry;

[0038] (3) Screening: the slurry is granulated, passed through a 200-mesh standard sampling sieve, and dried to obtain a uniform slurry;

[0039] (4) Heating and melting: put the uniform slurry into the preparation mold wrapped in aluminum foil, then put it into the heating device to melt the uniform slurry, and control the temperature at 165±5°C;

[0040] (5) Pressure curing: put the molte...

Embodiment 2

[0044] Hydrocarbon fuels for solid fuel ramjet engines, including, by mass percentage:

[0045] Hydrocarbon fuel pellets: 65% high-density polyethylene, 30% fully refined paraffin wax No. 58.

[0046] Carbon functional additives: carbon black 2%, graphite 3%.

[0047] The preparation method is:

[0048] (1) Weighing: Accurately weigh the formulations of each component in a dry environment, and put them into different containers for later use;

[0049] (2) Blending: Add the above components into a blender in turn for mixing, control the mixing temperature at 40°C, and mix for 90 minutes to obtain a slurry;

[0050] (3) Screening: the slurry is granulated, passed through a 200-mesh standard sampling sieve, and dried to obtain a uniform slurry;

[0051] (4) Heating and melting: put the uniform slurry into the preparation mold wrapped in aluminum foil, then put it into the heating device to melt the uniform slurry, and control the temperature at 165±5°C;

[0052] (5) Pressure ...

Embodiment 3

[0056] Hydrocarbon fuels for solid fuel ramjet engines, including, by mass percentage:

[0057] Hydrocarbon fuel pellets: 47.5% high-density polyethylene, 47.5% fully refined paraffin wax No. 58.

[0058] Carbon functional additives: carbon fiber 5%.

[0059] The preparation method is:

[0060] (1) Weighing: Accurately weigh the formulations of each component in a dry environment, and put them into different containers for later use;

[0061] (2) Blending: Add the above components into a blender for mixing, control the mixing temperature to 30°C, and mix for 80 minutes to obtain a slurry;

[0062] (3) Screening: the slurry is granulated, passed through a 200-mesh standard sampling sieve, and dried to obtain a uniform slurry;

[0063] (4) Heating and melting: put the uniform slurry into the preparation mold wrapped in aluminum foil, then put it into the heating device to melt the uniform slurry, and control the temperature at 155±5°C;

[0064] (5) Pressure curing: put the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Volume calorific value | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com