Method for additive manufacturing of copper on titanium alloy based on interactive treatment of laser and electrochemical deposition

A technology of additive manufacturing and interactive processing, applied in the direction of additive processing, electroforming, electrolysis, etc., can solve the problems of poor adhesion of deposited layers, harm to human health, complicated and cumbersome steps, etc., and achieve good adhesion and low cost , The effect of simple process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

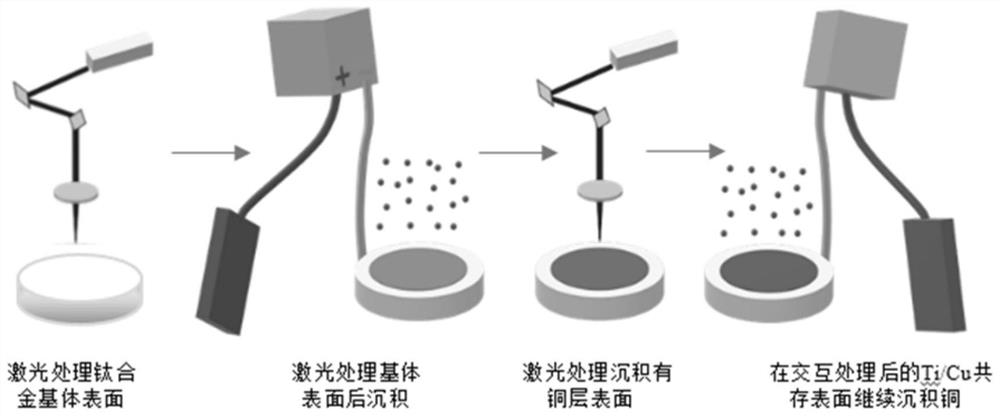

Method used

Image

Examples

Embodiment 1

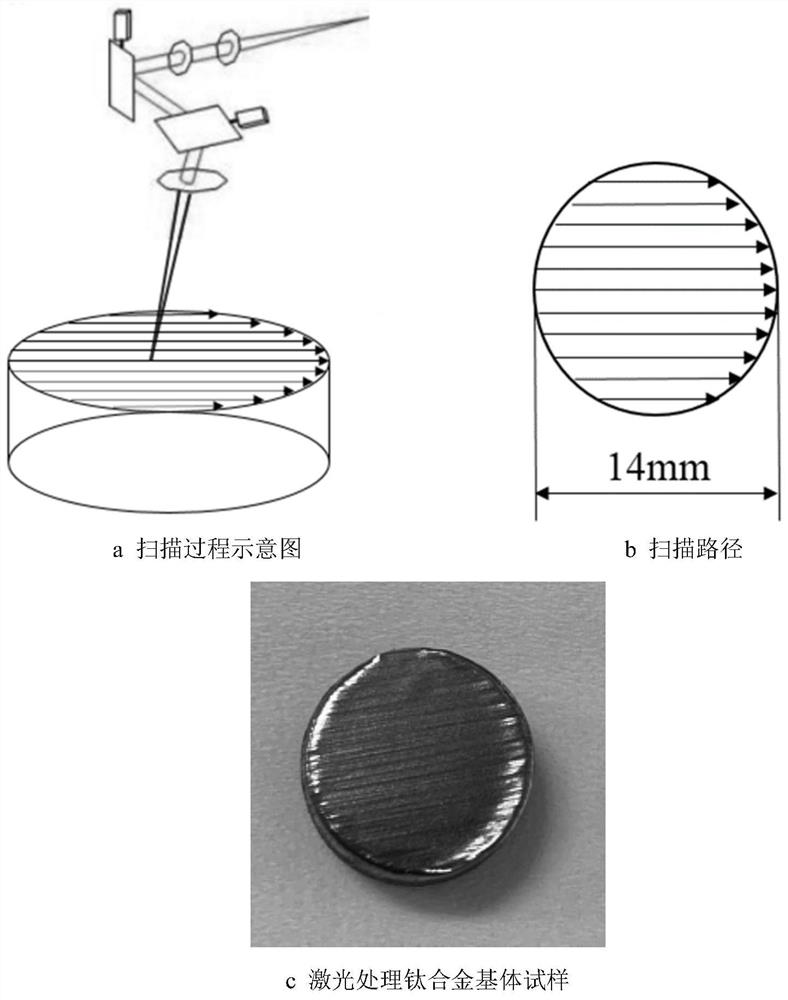

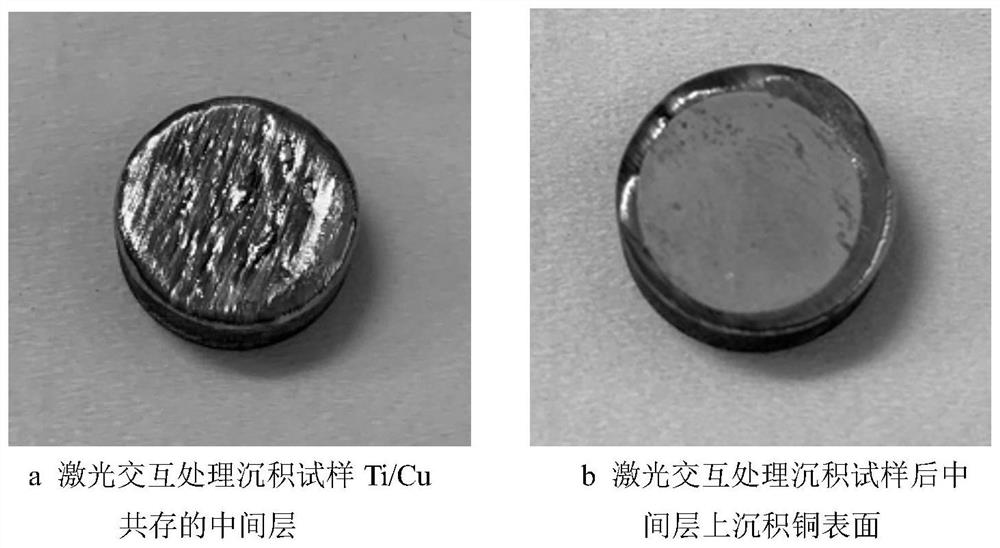

[0044]Use a 1500W galvanometer laser to perform laser melting treatment on the polished titanium alloy substrate sample, set the laser focal length to 517mm, laser power to 500W, scanning speed to 300mm / s, scanning mode to unidirectional scanning, and line spacing to 0.04 mm, forming a fused layer with a certain texture on the surface, such as figure 2 shown. Deposit the obtained sample in the electrodeposition system for 10 minutes to obtain the first layer of copper deposition layer, and then perform laser treatment on the sample deposited with copper, the laser scanning line spacing is 0.05mm / s, and the rest are the same as the first laser treatment Same, the first Ti / Cu interlayer was obtained; the obtained sample was subjected to laser treatment after electrodeposition for 10 min, and the laser treatment parameters were the same as the second data; the sample was deposited for the third time, and the deposition time was After 10 minutes, the deposition sample was obtain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com