Method for rapidly and accurately determining crystal axis orientation of gallium oxide monocrystals

An accurate measurement and gallium oxide technology, applied in the field of gallium oxide single crystal processing, can solve the problems of inaccuracy and slow detection, and achieve the effects of low technical requirements, weakened equipment dependence, and less crystal loss.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

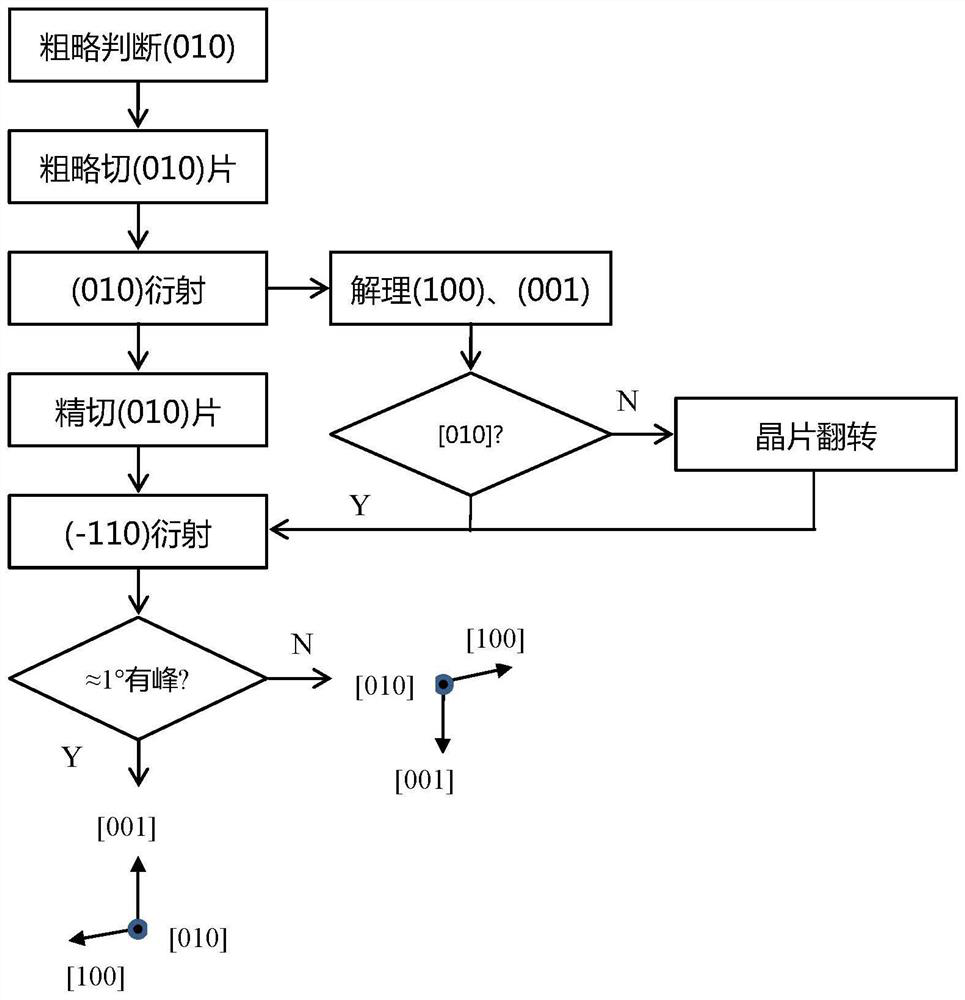

[0068] This embodiment provides an example of a method for quickly and accurately determining the crystallographic axis orientation of a gallium oxide single crystal, referring to figure 1 , the method includes the following steps:

[0069] S1. Preliminary judgment of the direction of the (010) crystal plane: take a gallium oxide crystal ingot to be tested, observe the surface of the gallium oxide crystal ingot, the plane perpendicular to the crystal fiber is the initial (010) crystal plane; among them, the gallium oxide crystal The choice of ingot is β-Ga 2 o 3 single crystal.

[0070] S2. Cutting the initial (010) crystal plane: fix the gallium oxide crystal ingot on the stage of the diamond wire cutting machine, and cut a small slice of crystal from the gallium oxide crystal ingot along the initial (010) crystal plane, denoted as S2 .1 Gallium oxide wafer, S2.1 The thickness of the gallium oxide wafer is 0.3 mm, and the cut gallium oxide ingot is recorded as the second g...

Embodiment 2

[0085] The difference between this embodiment and embodiment 1 is that the operating parameters and intermediate results of some steps in the detection process of the method are different, specifically including the following steps:

[0086] S1. Preliminary determination of the direction of the (010) crystal plane: the same as in Example 1;

[0087] S2. Cutting the initial (010) crystal plane: fix the gallium oxide crystal ingot on the stage of the diamond wire cutting machine, and cut a small slice of crystal from the gallium oxide crystal ingot along the initial (010) crystal plane, denoted as S2 .1 Gallium oxide wafer, S2.1 The thickness of the gallium oxide wafer is 1 mm, and the cut gallium oxide ingot is recorded as the second gallium oxide ingot;

[0088] S3. Determination of the declination angle of the initial (010) crystal plane: place the cut S2.1 gallium oxide wafer on the stage of the X-ray orientation instrument for X-ray diffraction to measure the angle between ...

Embodiment 3

[0099] The difference between this embodiment and embodiment 1 is that the operating parameters and intermediate results of some steps in the detection process of the method are different, specifically including the following steps:

[0100] S1. Preliminary determination of the direction of the (010) crystal plane: the same as in Example 1;

[0101] S2. Cutting the initial (010) crystal plane: fix the gallium oxide crystal ingot on the stage of the diamond wire cutting machine, and cut a thin slice of crystal from the gallium oxide crystal ingot along the initial (010) crystal plane, denoted as S2. 1 Gallium oxide wafer, S2.1 The thickness of the gallium oxide wafer is 0.4 mm, and the cut gallium oxide ingot is recorded as the second gallium oxide ingot;

[0102] S3. Determination of the declination angle of the initial (010) crystal plane: place the cut S2.1 gallium oxide wafer on the stage of the X-ray orientation instrument for X-ray diffraction to measure the angle between...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com