Novel flue gas desulfurization tower

A desulfurization tower and flue gas technology, applied in liquid degassing, gas treatment, separation methods, etc., can solve the problems of large gas bubble volume, foam overflow, and short residence time of flue gas, so as to reduce deposition and ensure cleanliness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

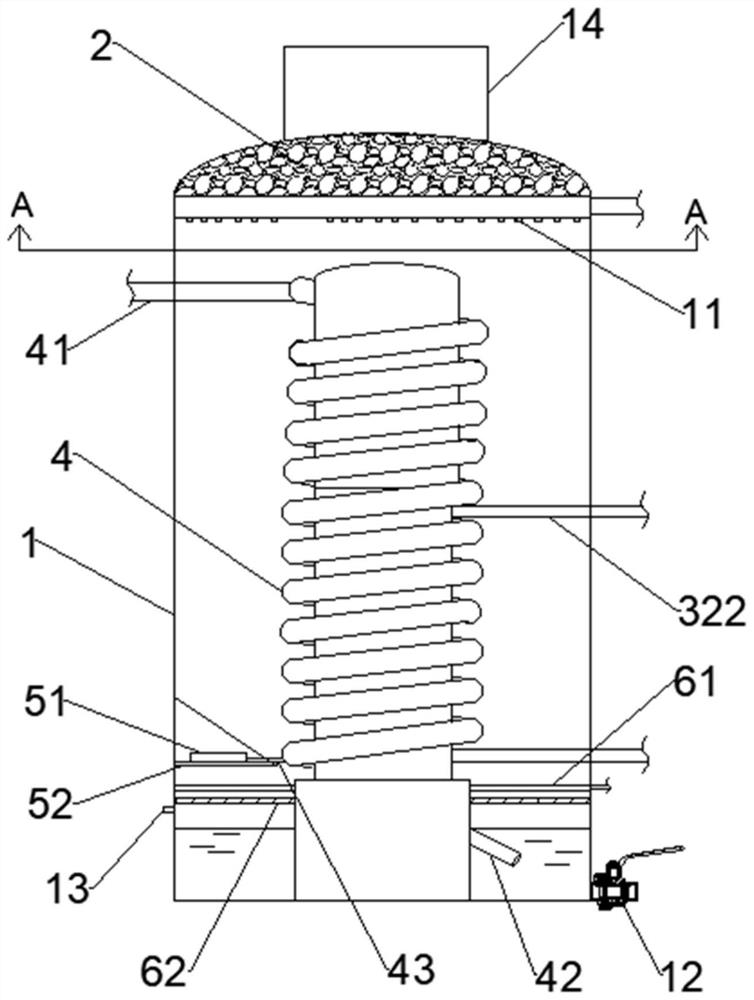

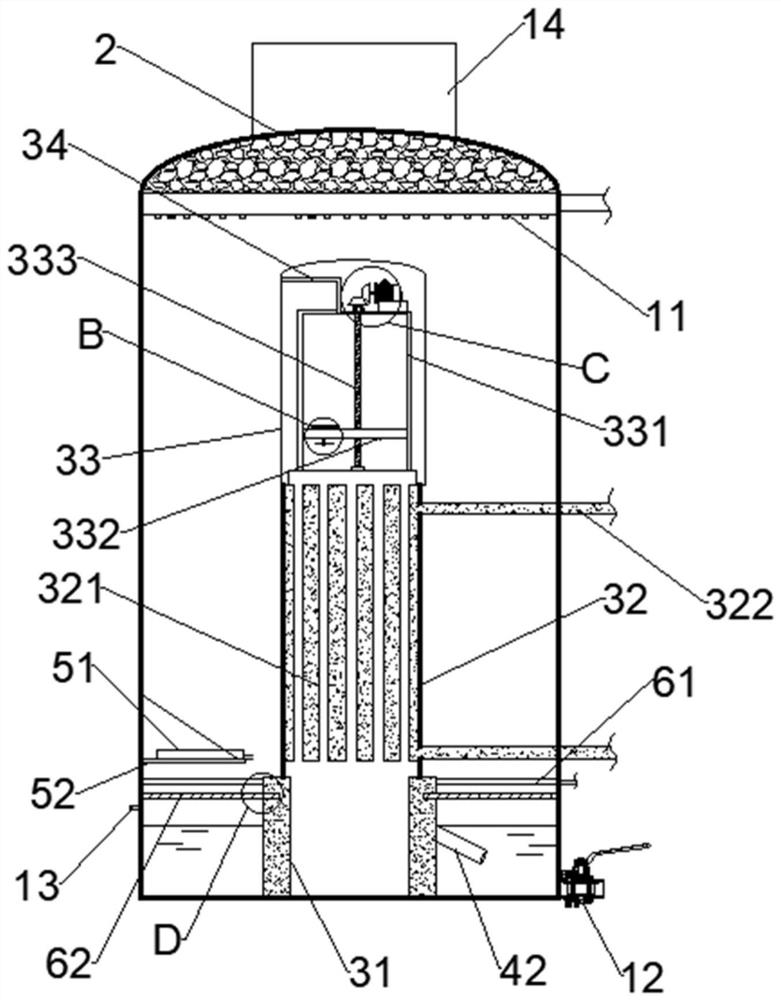

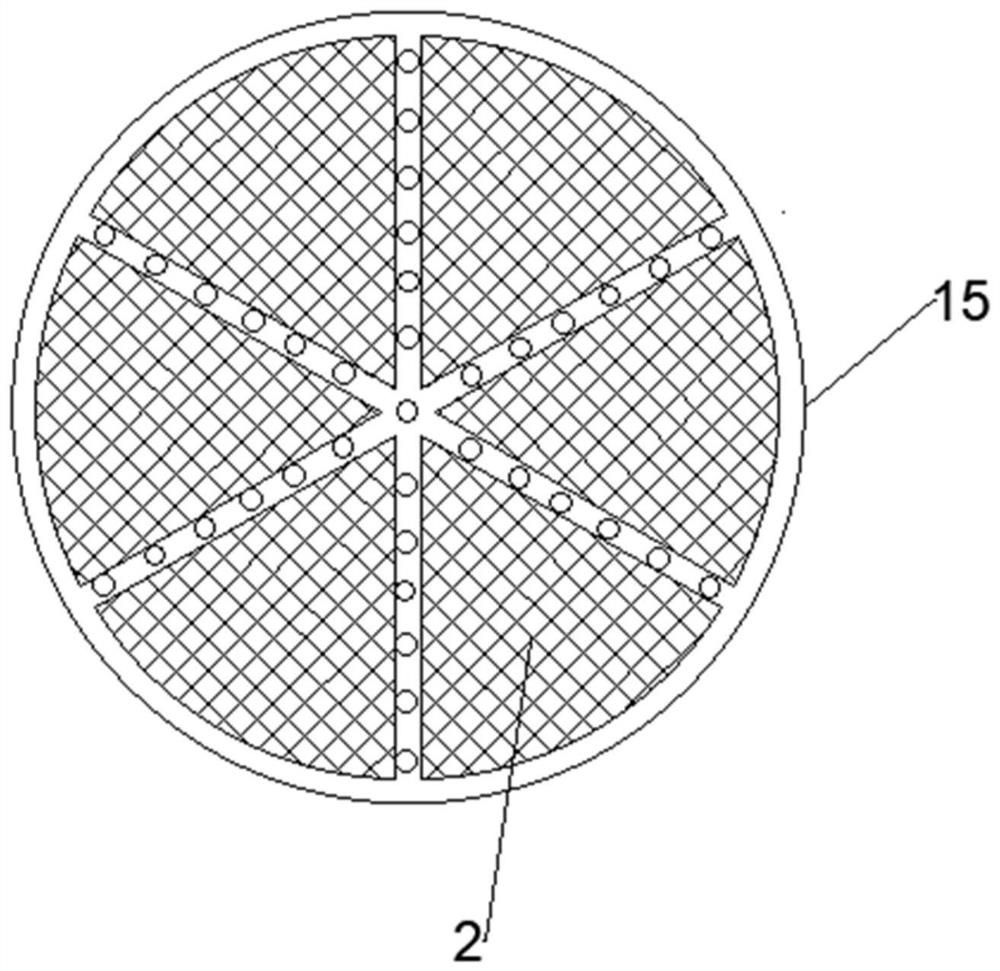

[0042] Such as figure 1 Shown is a new type of flue gas desulfurization tower, which is used to solve the problem that the desulfurization tower in the prior art cannot make full use of the heat in the flue gas, and at the same time can increase the residence time of the bubbles in the absorption liquid to improve the desulfurization effect of the flue gas. Moreover, the thickness of the foam layer can also be controlled, and its structure includes: a housing 1, a flue gas treatment pipe, a spiral pipe 4, and a defoaming mechanism. In the heat exchange layer 32, the heat of the flue gas is exchanged with the cooling medium, and the heat of the flue gas is recovered and pressed into the spiral tube 4 coiled outside the flue gas treatment pipe, and the spiral tube 4 is filled with an absorption liquid , the flue gas discharged from the flue gas treatment pipe flows into the bottom of the casing 1 along with the absorption liquid in the spiral pipe 4, and the mist of the absorpti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com