Carbon quantum dot modified polystyrene oil displacement material and preparation method thereof

A polystyrene, carbon quantum dot technology, applied in chemical instruments and methods, general water supply saving, drilling composition and other directions, can solve problems such as poor temperature resistance, reduce interfacial tension, improve oil recovery, good The effect of oil washing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Preparation of carboxylated carbon quantum dots: Mix 2 g of anhydrous citric acid and 20 mL of deionized water, place in an ultrasonic washing machine to completely dissolve the citric acid; then place in a microwave oven at 700W for 4 minutes to obtain a mixture. There is a certain solid residue in the obtained mixture, add 20mL of deionized water, place it in an ultrasonic washing machine, and ultrasonically disperse it evenly for 5 minutes; then transfer it to a centrifuge tube, and separate it for 5 minutes in a high-speed centrifuge at 8000r / min; collect the supernatant Carry out dialysis, transfer the supernatant into a 500-1000D dialysis bag, dialyze with deionized water for 48 hours, and change the water every 6 hours. The solution after the dialysis is transferred out for freeze-drying, and the obtained solid product is purified carboxylated carbon quantum dots.

Embodiment 2

[0025] Preparation of carboxylated carbon quantum dots: Mix 0.5g of anhydrous citric acid with 5mL of deionized water, then place it in an ultrasonic washing machine, ultrasonically disperse it for 10 minutes, and dissolve it completely; then place the solution in a microwave oven with a power of 400W for heating reaction After 8 minutes, a mixture containing carboxylated carbon quantum dots was obtained. Add 100mL of deionized water to the mixture containing carboxylated carbon quantum dots and ultrasonically disperse it for 30 minutes to make it evenly dispersed. If there is no solid residue in the mixture, dialyze it directly. If there is residue, use a high-speed centrifuge to separate and centrifuge at 8000r / min for 5-10min , retain the supernatant where the carboxylated carbon quantum dots are located; add the supernatant to a 500-1000D dialysis bag and dialyze with deionized water for 48 hours, add one-third of the volume of the dialysis bag during dialysis, and change i...

Embodiment 3

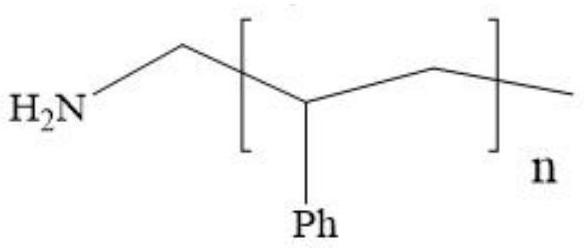

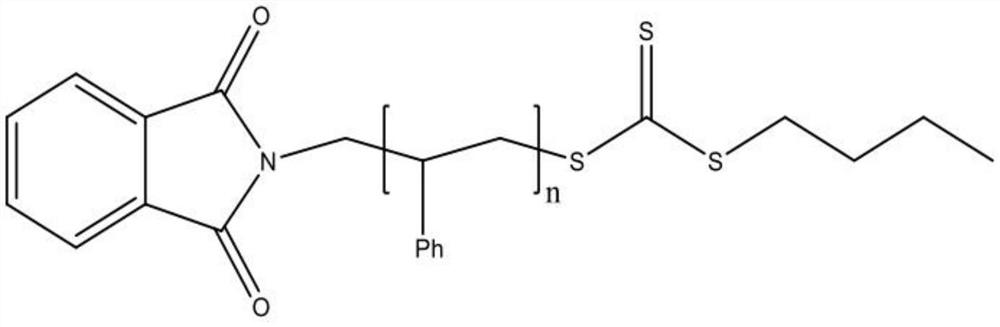

[0027] The preparation of mono-primary amino polystyrene comprises the following substeps:

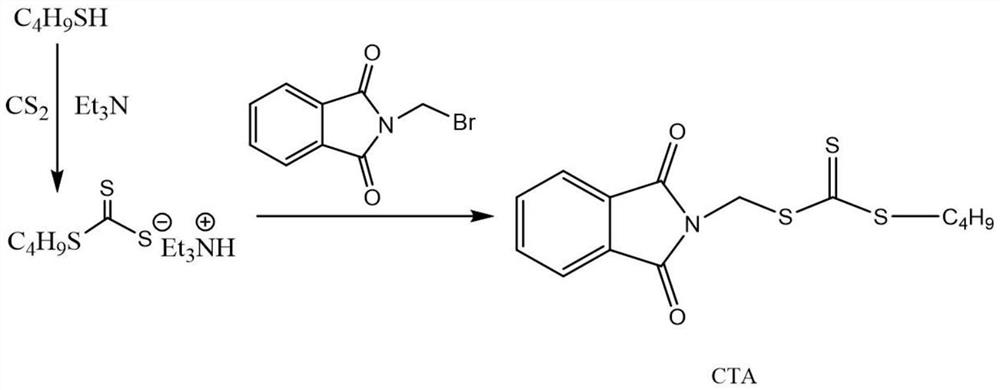

[0028] (1) Synthesis of chain transfer agent (CTA):

[0029] Add 3.57g of 1-butanethiol, 6.07g of carbon disulfide and 25ml of chloroform in a dry three-necked flask equipped with a polytetrafluoroethylene rotor, a constant pressure dropping funnel and a condenser tube, and slowly add 8.21g of triethylamine dropwise under stirring, The solution turned orange-yellow with the formation of the intermediate triethylaminobutyl trithiocarbonate. After the solution was stirred at room temperature for 3 hours, 9.59 g of N-bromomethylphthalimide was slowly added in batches, and the addition time was not less than 30 minutes. The solution of the mixture thickened with the formation of bromide salt, and the solution was continued to react at room temperature for 16h. After the reaction finishes, add 20ml chloroform to dilute the reaction mixture, and the organic phase is washed with deionized w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com