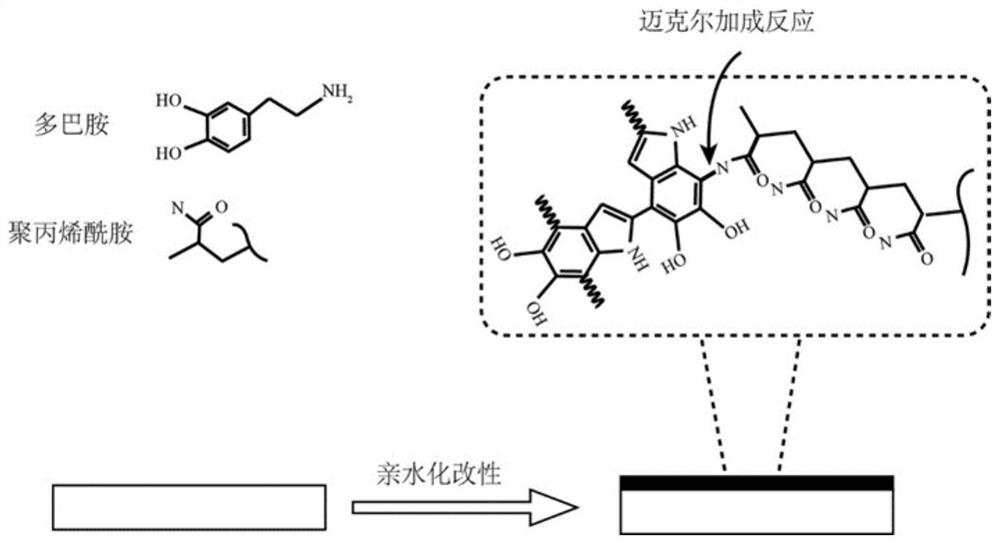

Coal seam moistening method based on mussel bionic principle

A bionic principle and coal seam technology, applied in earthwork drilling, safety devices, mining devices, etc., can solve the problems of coal seam water injection wetting effect to be improved, coal seam water permeability is poor, surface free energy is low, etc., to improve coal seam water injection wetting effect, reduction of dust production, good hydrophilic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

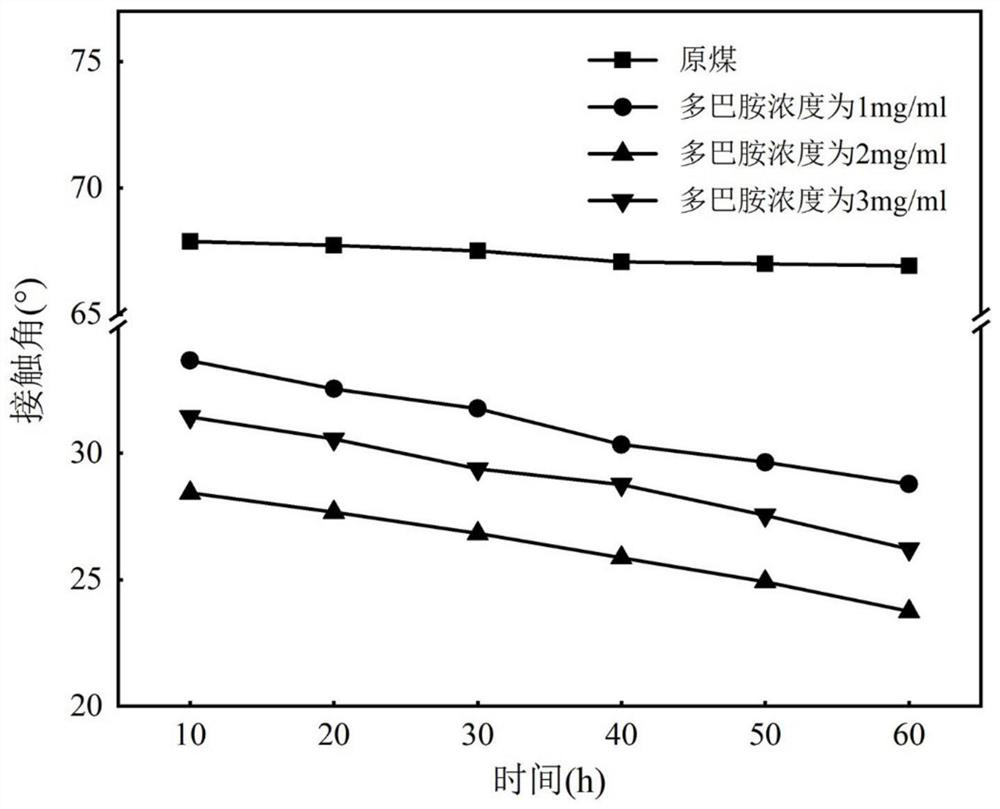

[0047] Set up four groups of wetting agents for coal seam water injection with different dopamine concentrations. The dopamine concentrations are set to 0, 1mg / mL, 2mg / mL, and 3mg / mL respectively. At this time, polyacrylamide is added according to the molar ratio of dopamine to 1:1. , the concentration of copper sulfate is 5.3mM, and the concentration of hydrogen peroxide is 26.1mM. The preparation process of the coal seam water injection wetting agent is as described in the summary of the invention. The prepared briquettes were placed in four prepared wetting agents for coal seam water injection with different concentrations of dopamine. After 30 minutes of deposition, the briquettes were taken out and dried, and then the contact angle experiment was carried out. The experimental results are as follows image 3 shown.

[0048] from image 3 It can be seen from the figure that the contact angle of the raw coal used in the experiment is about 70°, and the contact angle changes ...

Embodiment 2

[0050] Set five groups of different deposition times, 0, 15min, 30min, 45min, 60min respectively. At this time, the concentration of dopamine is 2mg / mL, and the molar ratio of polyacrylamide to dopamine is 1:1. The concentration of copper sulfate is 5.3mM, hydrogen peroxide concentration is 26.1mM. The preparation process of the coal seam water injection wetting agent is as described in the summary of the invention. The prepared coal cake was placed in the prepared coal seam water injection wetting agent, deposited and modified according to five groups of time gradients, then the coal cake was taken out and dried, and then the contact angle experiment was carried out. The experimental results are as follows Figure 4 shown.

[0051] from Figure 4 It can be seen that the contact angle of the coal sample decreases significantly after the coal seam water injection wetting agent is deposited and modified. When the deposition time is 15 min, the contact angle of the coal sample ...

Embodiment 3

[0053] Set the molar ratio of five groups of different polyacrylamide and dopamine dosing, respectively set the molar ratio of polyacrylamide and dopamine dosing to 0:1, 0.5:1, 1:1, 2:1, 4:1, this When the dopamine is 2mg / mL, the concentration of copper sulfate is 5.3mM, and the concentration of hydrogen peroxide is 26.1mM. The briquettes were placed in five groups of coal seam water injection wetting agents with different dosing ratios of polyacrylamide and dopamine. After 30 minutes of deposition, the briquettes were taken out and dried, and then the contact angle test was carried out. The experimental results are as follows Figure 5 shown.

[0054] from Figure 5 It can be seen from the figure that compared with the coal samples modified by pure dopamine solution, the contact angles of the coal samples modified by four different polyacrylamide and dopamine dosing ratios are significantly reduced, and with the With the increase of polyacrylamide concentration, the overall...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com