Fixing device and heat pump equipment

A technology of fixing devices and heat pumps, applied in lighting and heating equipment, measuring devices, mechanical equipment, etc., can solve the problems of low assembly efficiency, increased operation difficulty, inconvenient installation, etc., achieve fast assembly, improve operation accuracy, and simple structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

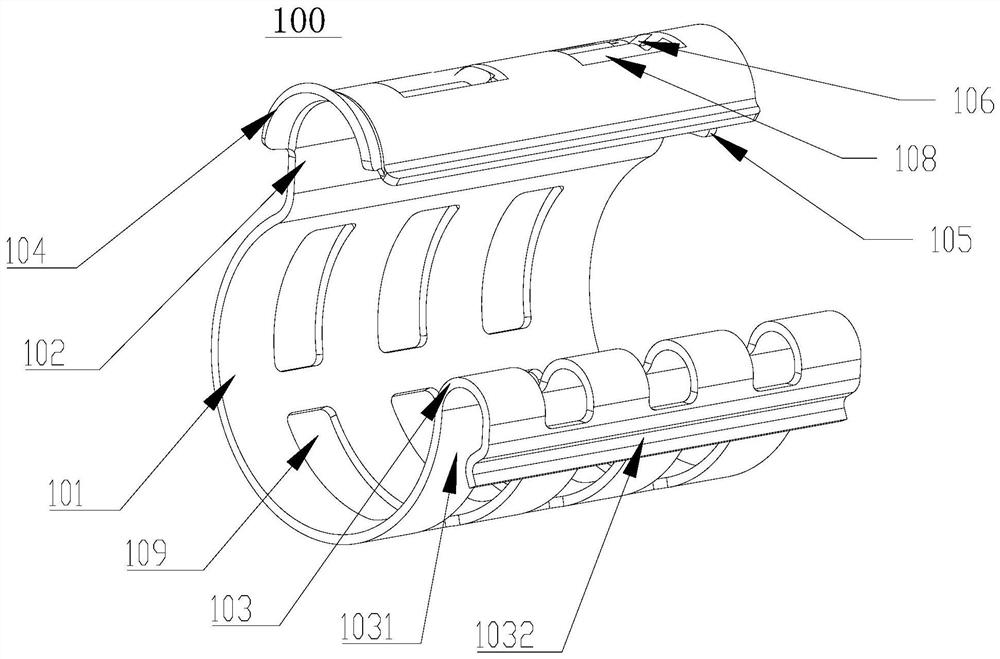

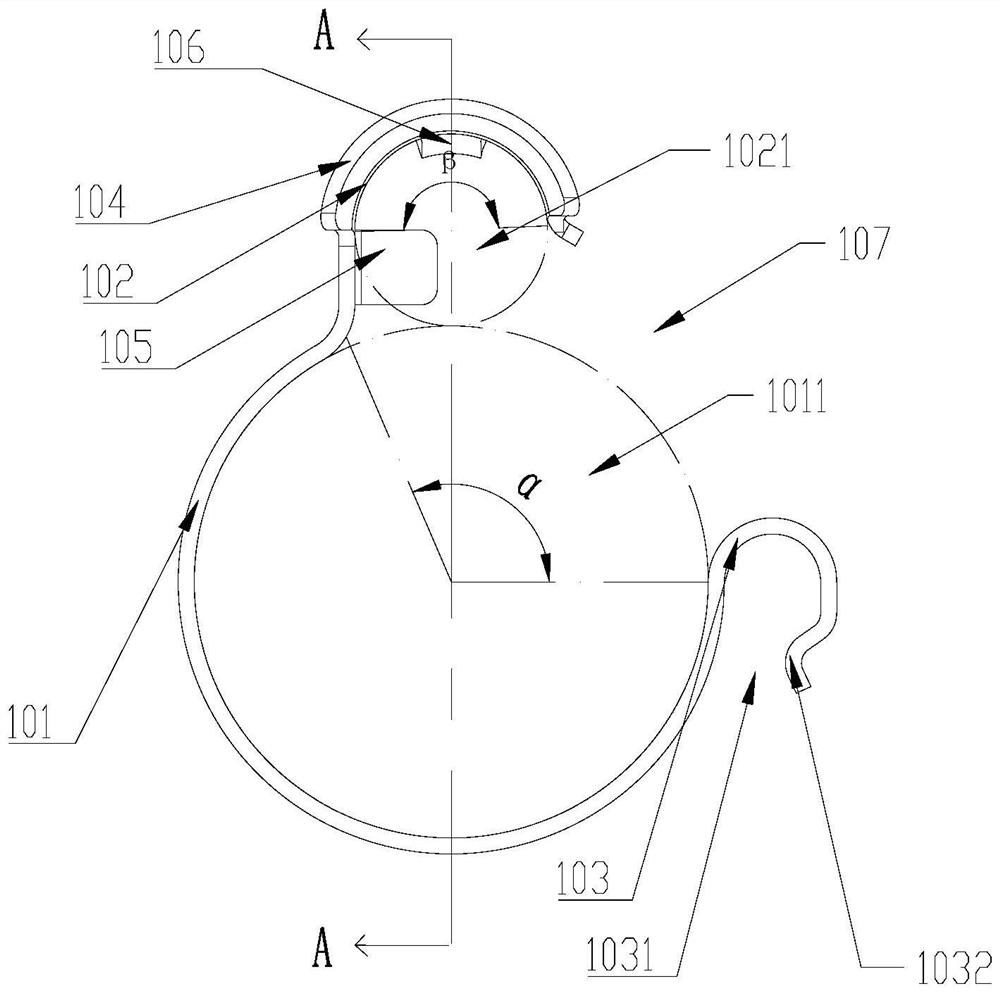

[0039] refer to Figure 1-5 As shown, the present invention discloses a fixing device 100. The fixing device 100 includes a first open sleeve 101 and a second open sleeve 102. The first open sleeve 101 is provided with a first opening 1011 in the axial direction, and the second opening The sleeve 102 is provided with a second opening 1021 in the axial direction; the first opening 1011 is disposed toward the second opening 1021, the first side of the first opening 1011 is connected to the first side of the second opening 1021, and the first side of the first opening 1011 is The two sides and the second side of the second opening 1021 are not connected, as the free side, forming the installation port 107 of the fixing device 100; the cylinder corresponding to the first opening sleeve 101 is outside the cylinder corresponding to the second opening sleeve 102 cut.

[0040] By setting the first open sleeve and the second open sleeve outwardly, the components installed in the two o...

Embodiment 2

[0050] This embodiment is a further optimization or limitation of Embodiment 1 or an equivalent replacement.

[0051] A fixing device 100, the fixing device 100 includes a first open sleeve 101, a second open sleeve 102, the first open sleeve 101, the second open sleeve 102 are provided with a first opening 1011, a second Two openings 1021; the first opening 1011 is opposite to the second opening 1021, the first side of the first opening 1011 is connected to the first side of the second opening 1021, the second side of the first opening 1011 and the second opening 1021 The second side is the free side, forming the installation port 107 of the fixing device 100; the corresponding cylinder of the first open sleeve 101 is circumscribed with the corresponding cylinder of the second open sleeve 102, and the radius of the first open sleeve 101 is greater than The radius of the second open sleeve 102 .

[0052] refer to figure 1 and figure 2 , wherein, the radian of the first ope...

Embodiment 3

[0060] This embodiment is a further optimization or limitation of embodiment 1 or embodiment 2 or an equivalent replacement.

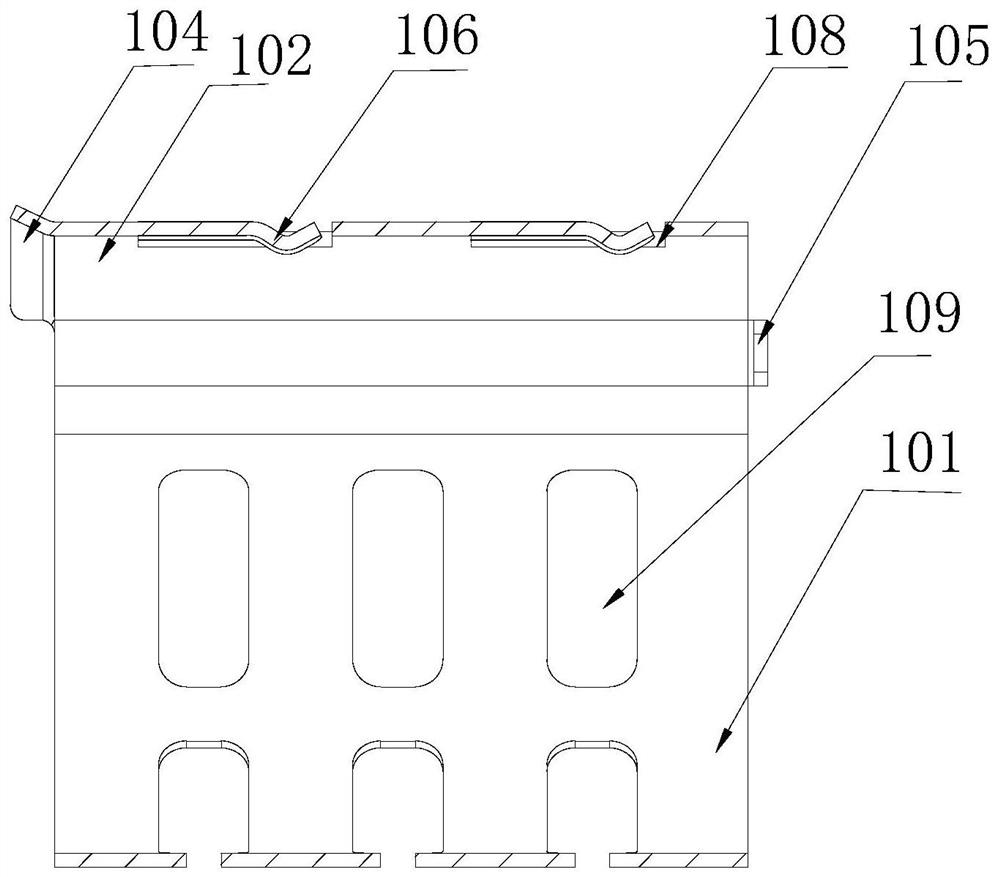

[0061] refer to figure 1 , image 3 and Figure 4 , the peripheral wall of the second open sleeve 102 is provided with a number of positioning holes 108, the elastic piece 106 is arranged in the positioning hole 108, the elastic piece 106 is inserted into the positioning hole 108, and the temperature sensing probe 300 is further compressed to make the temperature sensing The probe 300 fits closely with the temperature tube body 200 to be measured, so that the temperature measurement is more accurate.

[0062] Several hollow structures 109 are arranged on the peripheral wall of the first open sleeve 101, and the hollow structures 109 extend along the circumferential direction of the first open sleeve 101, so that the rigidity of the first open sleeve 101 is moderate, and the clamping installation is labor-saving convenient.

[0063] refer to figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com