Bearing disassembling, cleaning and assembling integrated equipment

A bearing assembly and bearing technology, applied in metal processing equipment, chemical instruments and methods, cleaning methods and appliances, etc., can solve problems such as wasting manpower and material resources, affecting cleaning time and rhythm, and economic loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

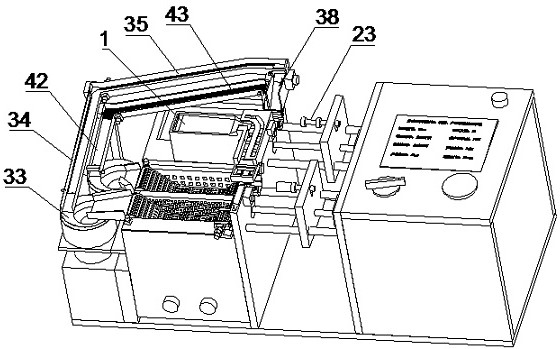

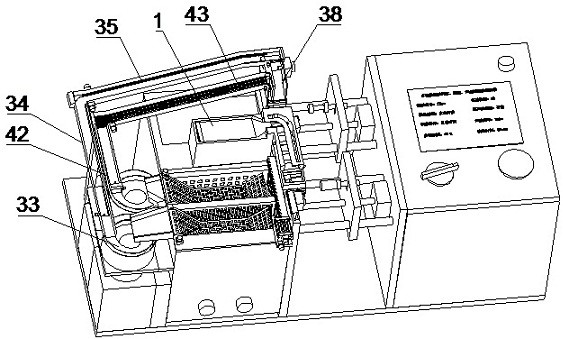

[0058] The integrated bearing disassembly, cleaning and assembly equipment in this embodiment includes a loading module, a disassembly module, a cleaning module and an assembly module.

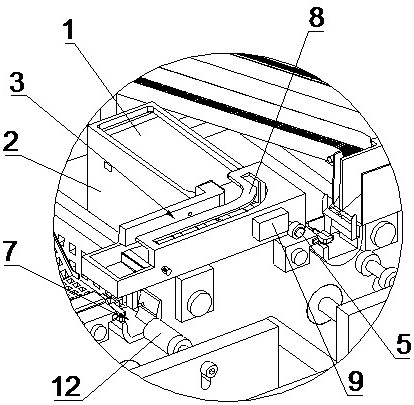

[0059] see Figure 1-4 , the feeding module in this embodiment includes a feeding vibration mechanism and a feeding conveying mechanism, and the described feeding vibrating mechanism includes a feeding tray 1 and a vibrating machine 2; the described feeding conveying mechanism includes a feeding conveying channel 3, an upper Material conveying belt 4 and feeding conveying motor 5, described feeding conveying belt 4 is arranged in the feeding conveying passage 3; Described feeding conveying passage 3 is provided with the passage for detecting whether there is bearing on the feeding conveying passage 3 Detection module6. The outlet end of the feeding tray 1 communicates with the inlet end of the feeding conveying channel 3, and the outlet end of the feeding tray 1 is a narrowing structure for l...

Embodiment 2

[0089] Different from Embodiment 1, the bearing inner ring and the inner and outer rings of the bearing in this embodiment are dried by a drying and blowing device after cleaning, so as to reduce waiting time and improve work efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com