Method for graded production of wet-process phosphoric acid

A technology of wet-process phosphoric acid and phosphoric acid, applied in chemical instruments and methods, phosphorus compounds, inorganic chemistry, etc., can solve problems such as difficult removal, achieve high product quality, round appearance, and improve market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

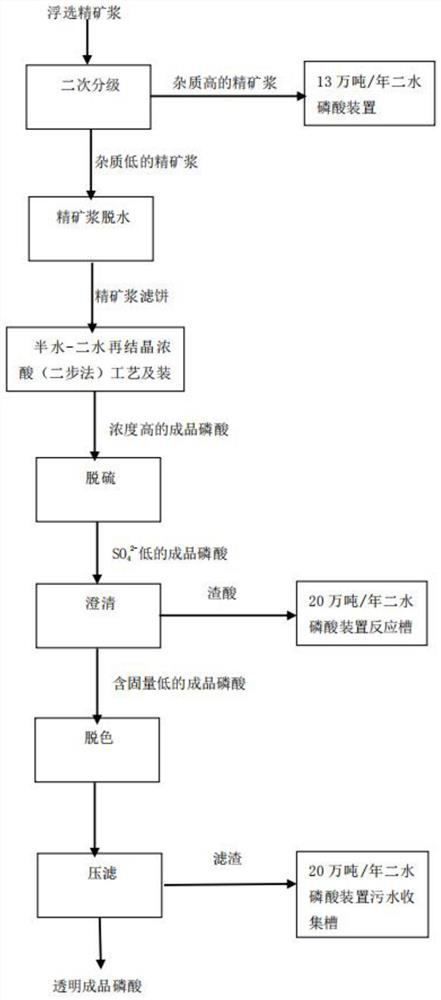

[0052] The wet-process phosphoric acid classification production method of the present invention comprises the following steps:

[0053] A step: the flotation concentrate pulp is secondary classified with a cyclone, dewatering is carried out by classifying the concentrate pulp with low impurities at the bottom to step B, and the top concentrate pulp with high impurities is settled and concentrated by the pulp thickener, and the thickener The bottom pulp enters the reaction tank of the 130,000-ton / year dihydrate phosphoric acid production unit, and the upper clarified water is used as the production water of the grinding unit.

[0054] Step B: the bottom concentrate pulp with low impurities in step A is dehydrated with a pressure filter, and after pressure filtration, a concentrate pulp filter cake is formed, and the water content of the filter cake is controlled at 14-16wt%. The filtrate is used for the production water of the phosphate rock grinding plant.

[0055] Step C: T...

Embodiment 2

[0065] The wet-process phosphoric acid classification production method of the present invention comprises the following steps:

[0066] A step: the flotation concentrate pulp is secondary classified with a cyclone, dewatering is carried out by classifying the concentrate pulp with low impurities at the bottom to step B, and the top concentrate pulp with high impurities is settled and concentrated by the pulp thickener, and the thickener The bottom pulp enters the reaction tank of the 130,000-ton / year dihydrate phosphoric acid production unit, and the upper clarified water is used as the production water of the grinding unit.

[0067]Step B: the bottom concentrate pulp with low impurities in step A is dewatered with a pressure filter, and a concentrate pulp filter cake is formed after the filter press, and the water content of the filter cake is controlled at 13-15wt%. The filtrate is used for the production water of the phosphate rock grinding plant.

[0068] Step C: The con...

Embodiment 3

[0074] The wet-process phosphoric acid classification production method of the present invention comprises the following steps:

[0075] A step: the flotation concentrate pulp is secondary classified with a cyclone, dewatering is carried out by classifying the concentrate pulp with low impurities at the bottom to step B, and the top concentrate pulp with high impurities is settled and concentrated by the pulp thickener, and the thickener The bottom pulp enters the reaction tank of the 130,000-ton / year dihydrate phosphoric acid production unit, and the upper clarified water is used as the production water of the grinding unit.

[0076] Step B: the bottom concentrate pulp with low impurities in step A is dewatered with a pressure filter, and after pressure filtration, a concentrate pulp filter cake is formed, and the water content of the filter cake is controlled at 12 to 14wt%. The filtrate is used for the production water of the phosphate rock grinding plant.

[0077] Step C:...

PUM

| Property | Measurement | Unit |

|---|---|---|

| iodine adsorption value | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com