Safflower yellow pigment and its preparation method and dyeing method

A technology of safflower yellow pigment and dyeing method, which is applied in the directions of dyeing method, chemical apparatus and method, organic dyes, etc., can solve problems such as waste of safflower yellow pigment, and achieve the effects of simple operation, good health and environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

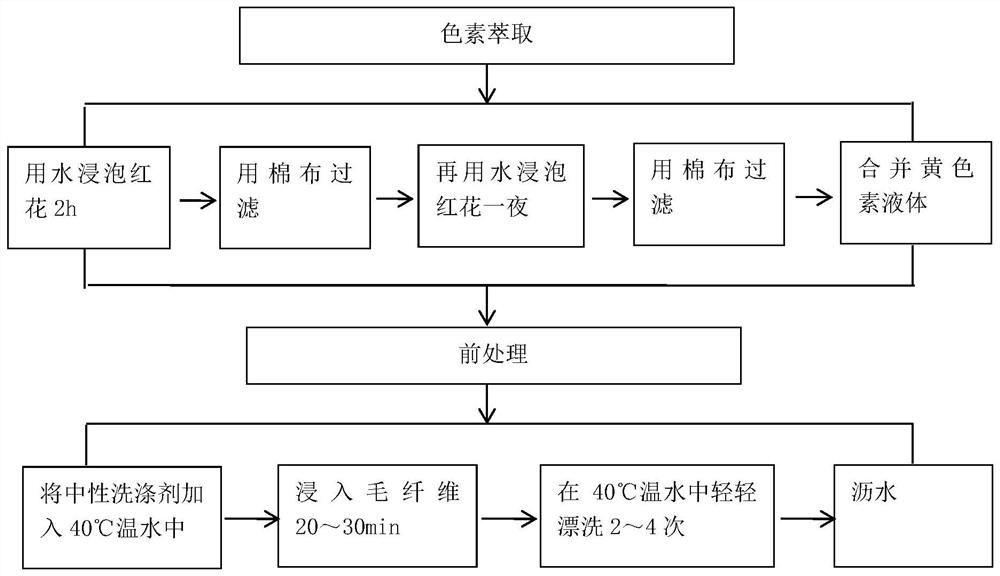

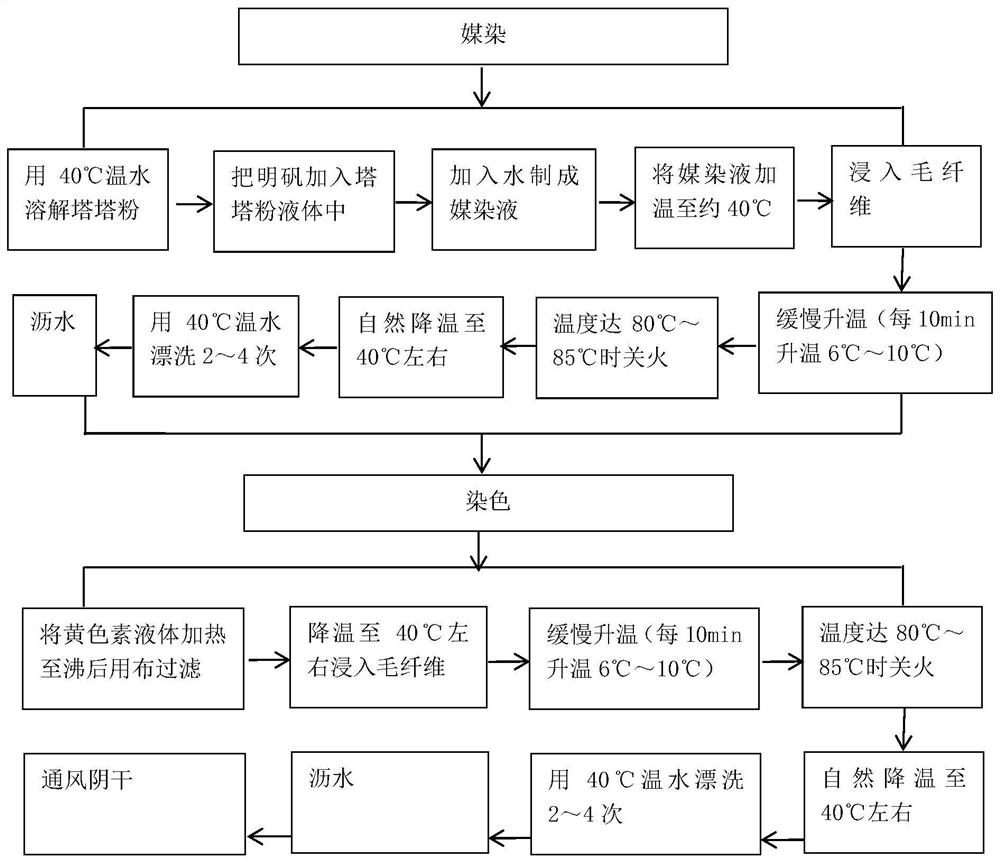

[0042] The inventors of the present invention found that safflower yellow pigment has good water solubility, while safflower red pigment is insoluble in water. Therefore, safflower yellow pigment can be obtained by dissolving in water. Specifically, a first aspect of the present invention provides a method for preparing safflower yellow pigment, which includes the following steps: soaking safflower in water, and collecting yellow pigment liquid after squeezing the safflower, wherein the The temperature of the water is 50°C or lower.

[0043] Specifically, in the present invention, the preparation method of the safflower yellow pigment comprises the following steps:

[0044] Step 1): After soaking the safflower in water below 50°C, squeeze it and let it stand to collect a yellow pigment liquid;

[0045] Step 2): put the extruded safflower in step 1) and soak it in water again, squeeze it again, and collect the secondary yellow pigment liquid; mix the primary yellow pigment li...

Embodiment 1

[0103] The present embodiment 1 and application example 1 use the following raw materials by weight: 50 g of bleached sheep wool, 200 g of dried safflower, 6 g of alum, and 1 g of cream of tartar.

[0104] Extraction of safflower yellow

[0105] 1. Soak safflower in 6L of water in a container, rub it with your hands and let it stand for 2 hours.

[0106] 2. Filter with cotton cloth to collect the yellow pigment liquid once.

[0107] 3. Put the filtered safflower into the container, inject 6L of water, stir evenly and soak for 12 hours.

[0108] 4. Filter, wrap the petals in cotton cloth and wring to extract the juice, collect the secondary yellow pigment liquid.

[0109] 5. Mix the yellow pigment liquid obtained twice and set aside.

Embodiment 2

[0133] The present embodiment 2 and application example 2 use the following raw materials by weight: 50 g of bleached mohair, 400 g of dried safflower, 6 g of alum, and 1 g of cream of tartar.

[0134] Extraction of safflower yellow

[0135] 1. Soak the safflower in 5.5L of water in a container, rub it with your hands and let it stand for 1.5 hours.

[0136] 2. Filter with cotton cloth to collect the yellow pigment liquid once.

[0137] 3. Put the safflower in the container again, inject 5.5L of water, stir evenly and soak for 13 hours.

[0138] 4. Filter, wrap the petals in cotton cloth and wring to extract the juice, collect the secondary yellow pigment liquid.

[0139] 5. Mix the yellow pigment liquid obtained twice and set aside.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com