Conductive nanofiber porous membrane material with nano metal particles loaded on the surface and preparation method thereof

A technology of nano-metal particles and conductive nano-technology, which is applied in carbon fiber, fiber treatment, textiles and papermaking, etc., can solve the problems such as the electrical conductivity of the material, and achieve good processability, increase the contact area, and improve the electrical conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

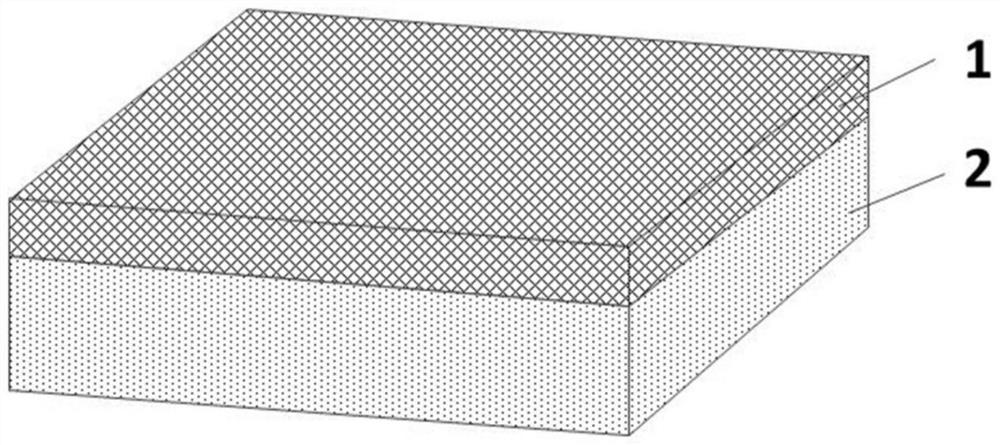

[0064] This embodiment discloses a conductive nanofiber porous membrane material loaded with nano metal particles on the surface, comprising the following preparation steps:

[0065] (1) Preparation of nanofiber suspension: disperse 10 g of ethylene vinyl alcohol copolymer nanofibers with a diameter of 100 to 200 nm in a mixed solvent with a mass ratio of 1000 g of ethanol to deionized water of 1:1, and stir to form nanofibers The ethylene vinyl alcohol copolymer nanofiber suspension with a solid content (mass percentage concentration) of 1 wt%, is sealed and stored.

[0066] (2) Preparation of nanofiber porous base membrane: apply the ethylene vinyl alcohol copolymer nanofiber suspension obtained in step (1) to one surface of the cotton fiber woven cloth by spraying, the coating thickness is 20 μm, and the coating thickness is 20 μm. Density is 10g / m 2 , and vacuum-dried at normal temperature to prepare a nanofiber porous base film with a pore diameter of 200-600 nm, which i...

Embodiment 2

[0073] This embodiment discloses a conductive nanofiber porous membrane material loaded with nano metal particles on the surface, comprising the following preparation steps:

[0074] (1) Preparation of nanofiber suspension: disperse 10 g of ethylene vinyl alcohol nanofibers with a diameter of 100 to 200 nm in a mixed solvent with a mass ratio of 1000 g of ethanol to deionized water of 1:1, and stir evenly to form a nanofiber solid. The ethylene vinyl alcohol copolymer nanofiber suspension with a content (mass percentage concentration) of 1 wt% is sealed and stored.

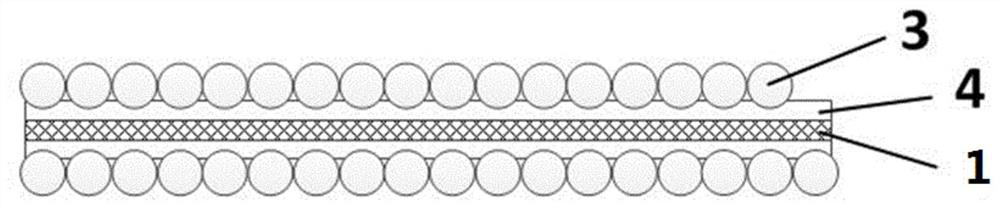

[0075] (2) Preparation of nanofiber porous base membrane: apply the ethylene vinyl alcohol copolymer nanofiber suspension obtained in step (1) on both surfaces of the polyacrylonitrile woven cloth by spraying, and the coating thickness is 10 μm. Coating density is 5g / m 2 , and vacuum-dried at normal temperature to prepare a nanofiber porous base membrane composed of polyacrylonitrile woven cloth and nanofiber coa...

Embodiment 3

[0082] (1) Preparation of nanofiber suspension: disperse 10 g of ethylene vinyl alcohol nanofibers with a diameter of 150 to 300 nm in a mixed solvent with a mass ratio of 1000 g of ethanol and deionized water of 1:1, and stir to form a solid content of nanofibers (mass percentage concentration) is 1wt% ethylene vinyl alcohol copolymer nanofiber suspension, sealed and preserved.

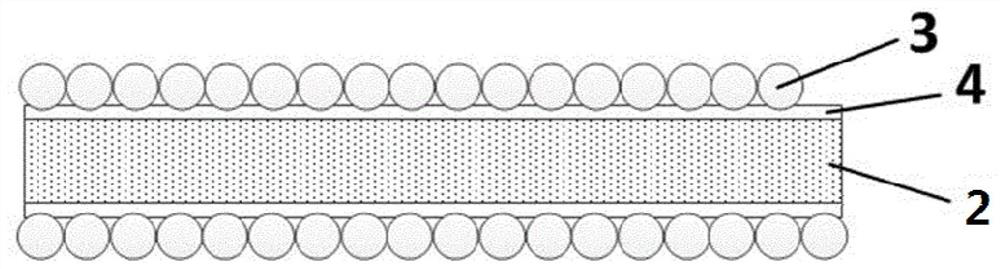

[0083] (2) Preparation of nanofiber porous base membrane: apply the ethylene vinyl alcohol copolymer nanofiber suspension obtained in step (1) to one surface of a polyacrylonitrile woven cloth by spraying, the coating thickness is 30 μm, and the coating thickness is 30 μm. The density is 20g / m 2 , and vacuum-dried at normal temperature to prepare a nanofiber porous base membrane composed of polyacrylonitrile woven cloth and nanofiber coating attached to the surface with a pore diameter of 500-800 nm.

[0084] (3) Configure dopamine hydrochloride aqueous solution: configure a tris-HCl (Tris-HCl) buff...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com