Thermal insulation material glue content determination method

A thermal insulation material and measurement method technology, applied in the direction of weighing by removing certain components, can solve problems such as too much difference between the real content of the glue and the detected content, inaccurate test results, cumbersome test process, etc., to avoid violent reactions The effect of uncontrollable temperature, shortened test time, and high accuracy of test results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

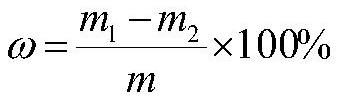

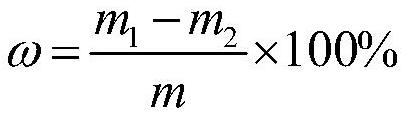

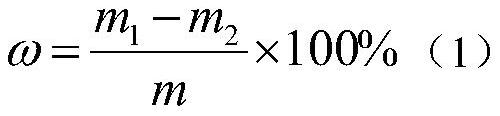

[0032] Weigh 2g of the T-1 thermal insulation material sample, accurate to 0.0001g, which is 2.0968g, put it in a 150mL beaker with constant weight, weigh the total mass of the sample and the beaker, which is 86.2641g, add acetone and ethyl acetate Put 40mL of the mixed solvent prepared by ester at a weight ratio of 1:3 into the beaker containing the sample, heat it in a water bath at 35°C, stir for 1 min to fully disperse the sample in the beaker, let it stand for 1 min for a little precipitation, pour out the cloudy liquid, and leave Put the black floc (carbon fiber braid) in the beaker, add the mixed solvent repeatedly to dissolve it 4 times, until the mixed solvent solution is clear and translucent after stirring and dissolving, finally pour out the liquid, put the beaker and the insoluble matter in the oven at 130°C After drying for 0.5h, the solution in the beaker was completely dried up, transferred to a desiccator to cool to room temperature, and weighed, which was 85.3...

Embodiment 2

[0042] Weigh 2g of the T-1 thermal insulation material sample, accurate to 0.0001g, which is 2.2282g, put it in a 150mL beaker with constant weight, weigh the total mass of the sample and the beaker, which is 85.0760g, add acetone and ethyl acetate Put 40mL of the mixed solvent prepared by ester at a weight ratio of 1:2 into the beaker containing the sample, heat it in a water bath at 40°C, stir for 2 minutes to fully disperse the sample in the beaker, let it stand for 2 minutes, and then pour out the cloudy liquid after a little precipitation. Put the black floc (carbon fiber braid) in the beaker, add the mixed solvent repeatedly to dissolve 5 times, until the mixed solvent is clear and translucent after stirring and dissolving, finally pour out the liquid, put the beaker and the insoluble matter in the oven at 150°C for drying Dry for 0.5h until the solution in the beaker is completely dry, transfer it into a desiccator to cool to room temperature, and weigh the mass, which i...

Embodiment 3

[0046] Weigh 2.0132g of the T-1 thermal insulation material sample, place it in a 150mL beaker with constant weight, weigh the total mass of the sample and the beaker, which is 84.7808g, add acetone and ethyl acetate at a weight ratio of 1:2 Put 40mL of mixed solvent in the beaker containing the sample, heat it in a water bath at 40°C, stir for 2 minutes to fully disperse the sample in the beaker, let it stand for 1 minute to settle slightly, and then pour out the turbid liquid, leaving black floc (carbon fiber braided fabric) In the beaker, repeatedly add the mixed solvent to dissolve 4 times until the mixed solvent solution is clear and translucent after stirring and dissolving, and finally pour out the liquid, put the beaker and the insoluble matter in the oven at 130°C for 1 hour, until the solution in the beaker is completely Dry, move into a desiccator to cool to room temperature, weigh the mass, which is 83.9143g. Calculate the glue content based on the reduced mass of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com